stickandtin

Members-

Posts

91 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by stickandtin

-

Hi Bob, I know I can call you anytime and I appreciate that. I just didn't want to trouble you with basic questions that I felt could be asked/answered on the forum. I'll give you a call next week. Thanks!!

-

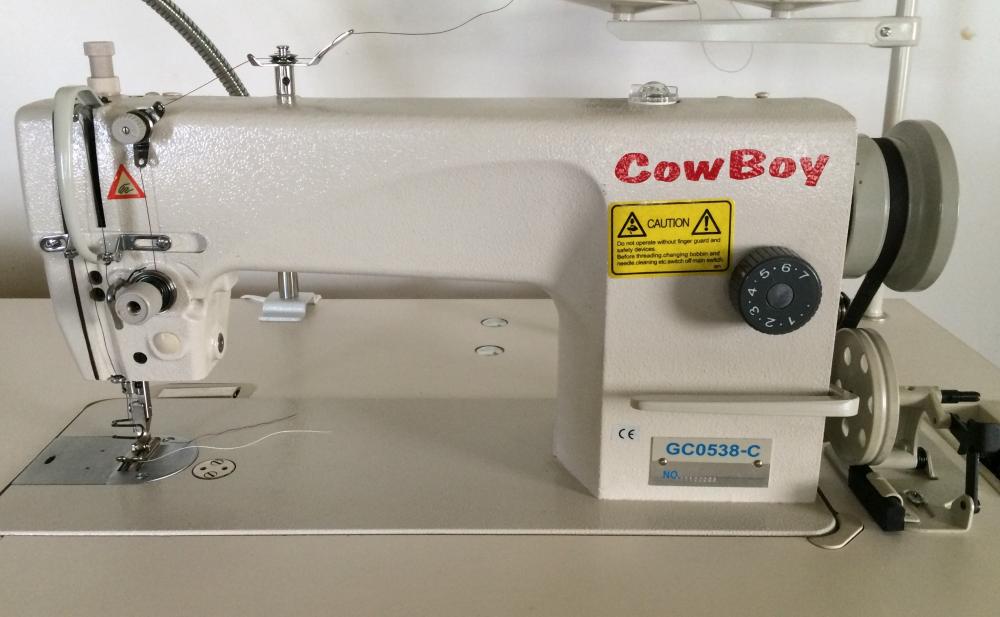

Gregspitz, thank for sending the video. That is some slowwwww sewing. Uwe.....the first industrial machine we ever purchased was the Juki. Since it had an English translation, I assumed all manuals would be that way. Owners manuals for every power tool I buy come in several languages. Again, yes I know I can call Bob. Calling Bob will be a last resort as I am guessing he stays pretty busy and I choose not to bother him with newbie questions. This is why I am asking on this forum. Every day I see posts from people asking details about machines and others sharing that info. I would like to hear from people who are using a Cowboy 538(or same type machine branded with a different name)in some kind of business or hobby. Back to needle size, thread range and other minutia....thought that would be in the manual and it might be. I just can't read Chinese LOL.

-

-

-

Mikesc.....yes, I can place a call to Bob. I just thought maybe some other people on this forum may own and use this model machine and would share some info about it.

-

We ordered a Cowboy 538 from Toledo Industrial. It arrived yesterday. As usual, Bob Kovar was wonderful to deal with and we got the machine in less than a week(Toledo to Lubbock, Tx) from the time we ordered it. We bought the machine to primarily sew draperies. However, we are wondering what else this needle feed machine can be used for and what it's capabilities are. Can it sew leather, vinyl, canvas? What thicknesses? What range of needles and thread can it handle? As far as manuals to operate the machine, the main book is written in Chinese. Why does Cowboy include a user manual that is written only in Chinese? Other than some illustrations it's of no use to us. There was another smaller supplement written in English that covered some basics. Our Juki manual at least had English translations. Because the main manual is in Chinese, I'm sure we will have plenty of questions about operating the machine. We would appreciate any input on other uses for and capabilities of this machine. Thanks!

-

Did some more digging through pics on the Internet and found these two chairs. The chairs in the first pic are made from leather panels sewed together. Guy that made those claims he used "1/4 inch saddle leather", whatever that means. Second chair is laced with leather. Not sure how that is done either because I assume you can only make a leather strip as long as the hide is. Can my juki 1541 sew through 1/2 inch of leather?Does anyone have any idea how the lacing on the chair in the second pic was made?

-

I was digging around the internet trying to identify what type of seat material these frames originally had. Finally struck pay dirt. They are literally called basket chairs. A large woven tapered basket made out of some kind of cane material was inserted inside the ring. The only thing holding the basket inside the frame is the friction created by the taper. I can see now why the frames were bare. The cane had broken or rotted long ago. I have no idea how to weave a basket LOL. I am now exploring ways to modify the frames so I can create seats for them using leather.

-

-

Leatherwytch, thank you for the help. I have no idea how to weave leather to form a seat. Weaving never crossed my mind as an option, but that approach does make a lot of sense. I was originallythinking along the lines of sewing solid pieces to form the seat then somehow attaching that to the frame. Honestly, with my lack of knowledge about working with leather or leather weaving this project may be way over my head.

-

Found these frames at a junk store and was thinking about trying to cover them in leather. I know nothing about leather, but I do have a juki 1541S to sew on. What kind of leather do you recommend trying to make the seats out of? Is my juki the right machine to sew seats for these frames? What would be the best way to attach the leather to the frames? asked these questions in another subgroup but didn't get any response. Thought maybe I asked in wrong area so trying this one. Thanks for any help or advice.

-

Acapulco style chairs

stickandtin replied to stickandtin's topic in Furniture: Inlays and Upholstery

Maybe I asked this question in the wrong subgroup. After looking around here, it seems to be a place to showcase projects that are finished rather than ask questions about how to do something. I'll try another area. Thanks. -

Acapulco style chairs

stickandtin replied to stickandtin's topic in Furniture: Inlays and Upholstery

-

Found these frames at a junk store and was thinking about trying to cover them in leather. I know nothing about leather, but I do have a juki 1541S to sew on. What kind of leather do you recommend trying to make the seats out of? Is my juki the right machine to sew seats for these frames? What would be the best way to attach the leather to the frames? Thanks for any help and advice.

-

Juki 1541S bobbin case problem

stickandtin replied to stickandtin's topic in Leather Sewing Machines

Tried the socket approach to getting rid of the dimple. My sockets have rounded edges so couldn't get close enough to the dimple. Went with the dremel tool and had success polishing off that dimple. Put bobbin back in basket and everything works perfectly. Wife is sewing merrily along again. Thanks everyone for the help. -

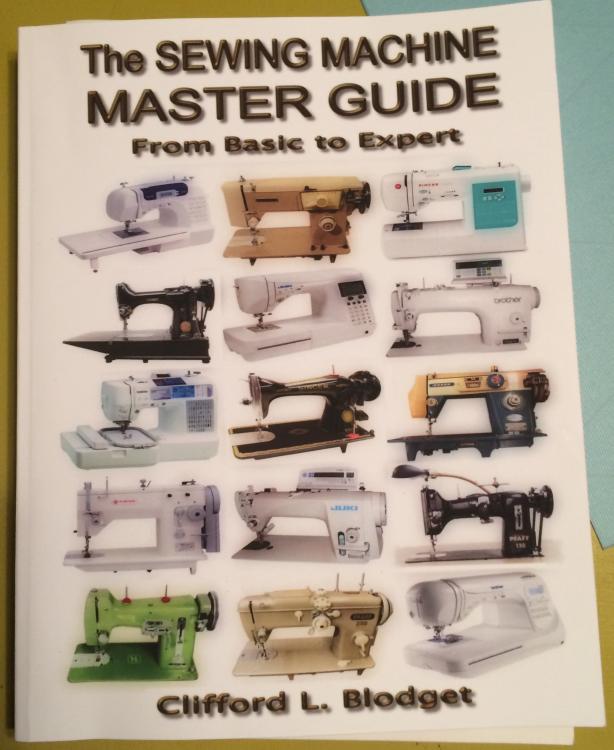

While digging around the Internet in an attempt to educate myself about sewing machines I found a reference to a book. It's called "The Sewing Machine Master Guide From Basic to Expert" by Clifford L. Blodget. Ordered a copy from Amazon and got it yesterday. For newbies like me who never sat in front of a sewing machine before, this book is very helpful. The book covers home and industrial machines. It explains basic things like how a sewing machine works, what the different parts are called, needle options, thread size, how to set machine thread tension, how to set bobbin thread tension, what correct stiches should look like and much more. I'm only about a third of the way into the book and I feel a whole lot less lost. Many of the questions I see asked on this forum by beginners like me are answered in this book. Has anyone else here looked at it?

-

Juki 1541S bobbin case problem

stickandtin replied to stickandtin's topic in Leather Sewing Machines

Great advice Eric and Uwe. Thanks for the help. -

Juki 1541S bobbin case problem

stickandtin replied to stickandtin's topic in Leather Sewing Machines

This forum is the greatest sewing forum on the Internet! -

Juki 1541S bobbin case problem

stickandtin replied to stickandtin's topic in Leather Sewing Machines

Thanks Uwe. Have any idea what caused the needle to hit the basket like that? -

Juki 1541S bobbin case problem

stickandtin replied to stickandtin's topic in Leather Sewing Machines

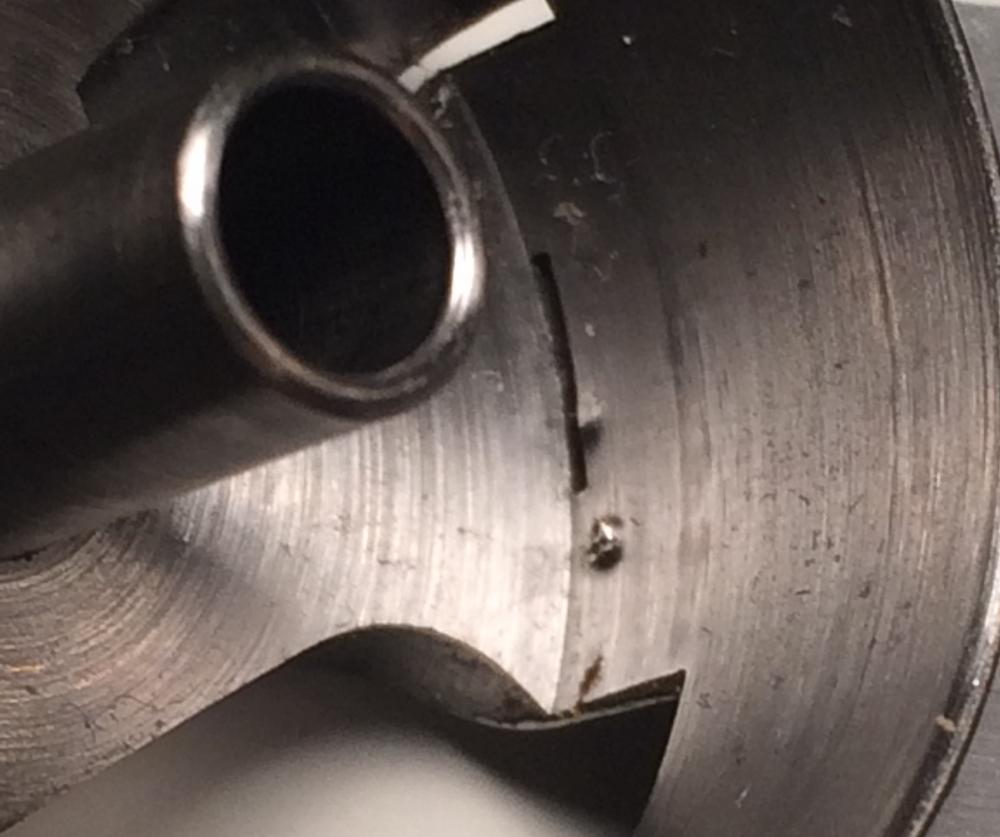

This is the little dimple I'm seeing. The safety clutch did pop right before all this started happening. Wife was sewing over several layers of a marine vinyl seam. -

Juki 1541S bobbin case problem

stickandtin replied to stickandtin's topic in Leather Sewing Machines

Took disc out. Inserted bobbin and bobbin still binds and won't turn. I think I may have found the problem. Looks like the needle could have hit the bobbin case and created a little dimple inside the bobbin case and that is what the bobbin is binding on. I'll take a pic of what I'm looking at and post. -

Juki 1541S bobbin case problem

stickandtin replied to stickandtin's topic in Leather Sewing Machines

Ok, got the disc back in the bobbin case but bobbin turns a little and sticks. Then I can't pull any bobbin thread. I think the holes in the bobbin are catching on those little arms and not allowing the bobbin to turn. Does this make any sense? What's the purpose of that disc anyway? -

Juki 1541S bobbin case problem

stickandtin replied to stickandtin's topic in Leather Sewing Machines

-

Wife was merrily sewing along and all of a sudden bobbin thread started binding and breaking. Took bobbin case out and couldn't pull thread. Took bobbin out and thread was bound up in bobbin. Unwound several feet of thread, put bobbin back in case and put back in machine. Tried sewing a couple of stitches and same thing happens. Thread breaks. Take bobbin case out and can't pull thread off bobbin. Take bobbin out again and thread is bound up on bobbin. Wind new bobbin, put back in machine. Same thing happens. Take bobbin case out, remove bobbin and inspect the case. Inside there is a blue black metal disc looking thing with little arms. Arms look worn and maybe bent up. Take the disc out to inspect, now I can't get it back in. Is this disc damaged? Which way does it go back in? Thanks for any help

-

Best machine for non leather application

stickandtin replied to stickandtin's topic in Leather Sewing Machines

Eric, you make a valid point about dealer support when buying a new machine. Bob at Toledo industrial has been great to work with after buying our Juki from him. We have pretty much decided to buy the cowboy 538. Thanks to everyone who took the time to post help, opinions, photos and advice.