Chopinzee

Members-

Posts

15 -

Joined

-

Last visited

Profile Information

-

Location

Boston, MA, USA

-

Interests

piano, photography, south indian cooking, garment sewing

LW Info

-

Leatherwork Specialty

just getting started--total newb

-

Interested in learning about

bag making

-

How did you find leatherworker.net?

google

Recent Profile Visitors

1,924 profile views

Chopinzee's Achievements

Member (2/4)

-

I made a wallet for a friend recently, and dip-dyed the pieces. I sealed both sides with a few coats of Resolene. The outside is holding up fine, but the flesh side is turning all his credit cards orange!! It's not a big deal in his case (says he doesn't mind "personalized" cards, hehe) but I'd like to avoid this problem in the future. I know one option is to leave the flesh side uncolored, but I really don't like the look of almost-white leather against dark exteriors. Does anyone have other solutions? I've seen a brown colored Resolene for sale online, but don't know if that would work any better.

-

Thanks Ferg, good to know about the fray-stop. I have some interfacing I can strengthen the fabric with as well. Been wondering if it would be more appropriate to use a running stitch in this situation so I don't have to worry about returning a needle through the same hole in the fabric? Then I could just use a sharper needle and it would go between the fibers of the fabric rather than making holes. I'm sewing in a zippered lining and wanted stitching around the zipper, and my chisel really doesn't want to create anything usable on the zipper-tape/lining layer.

-

This has probably been covered in a previous thread at some point, but for the life of me I can't find where! How do you all sew leather to fabric? I've been saddle stitching my leather, but I'm pretty sure if I tried that with fabric on one side, the second needle wouldn't go back through the same place the first needle came out unless I prepunched holes in the fabric--which won't work since the fabric frays like mad. There must be a simple solution... I know I can use glue, but isn't there some way to hand-stitch?

-

Oh, you CAN true the edges afterwards... thank goodness! Earlier I had tried sanding, but just managed to rough up the edges without actually taking anything off, so I figured that couldn't be the solution. But I was probably just not persistent enough. I don't have a belt sander, so maybe it's time to get out the dremel tool.... I was prepared for stitching/dyeing/finishing to be hard, but I had no idea I wouldn't even make it past the cutting stage.

-

Just started a first attempt at a project with veg tanned leather; very simple wallet pattern. Here's my problem: I cut the darn thing out 5 times, wasted a TON of leather, and still can't seem to cut pieces that match. They're not off by much, but the edges just don't line up perfectly together. I'm sure my pattern itself was cut accurately (I used scissors, and cut in the center of the printed lines). It's just cutting the actual leather that I can't seem to be accurate.... I'm using a fresh blade on a utility knife, a cutting mat, and a straightedge, but I just don't have the control to cut to within a millimeter. (Or the vision to SEE to within a millimeter!) Is there any way to "true up" the pieces with each other AFTER they've been cut?

-

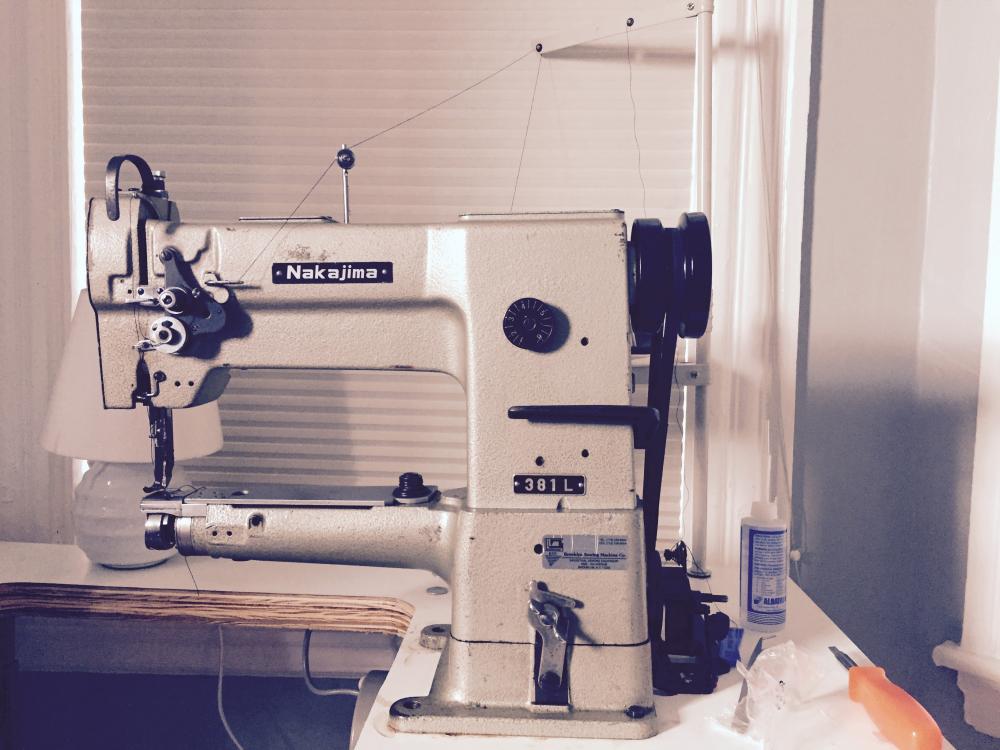

Thanks Glenn, That makes sense. A few things in the 245 look slightly different but it's close enough that if I ever need to take it in to a mechanic, I think with the 245 manual they could figure it out. I'm liking the machine so far; gotta get used to the speed of the clutch motor! Hannah

-

And I just posted a quick video of it sewing:

-

-

I just purchased a "new" (only new to me--actually quite old) machine for sewing leather. It is a cylinder bed Nakajima 381L machine with a Consew clutch motor. I figured it was a safe choice because I knew it was well maintained and the previous owner had used it to make exactly the kind of stuff I want to use it for (lightweight bags and wallets). Now that I have it at home, I'm realizing what a complete newbie I am at this, and how difficult it is to set everything up without a manual--so I decided to send an SOS to you folks to see if anyone knows more about this machine--or even a similar machine that would be easier to find a manual for. After googling a few different machines, it *looks* most similar to the Juki DSC series. It lost a bit of oil on the trip from NY, and the markings for where to oil it have all rubbed off. Any thoughts on what needles and thread to use?

-

Introduction And Question About Making Bags

Chopinzee replied to Chopinzee's topic in How Do I Do That?

You folks are awesome--this is all VERY helpful! -

Introduction And Question About Making Bags

Chopinzee replied to Chopinzee's topic in How Do I Do That?

Thanks! I'll definitely try both the Bontex and the Tandy Bag Stiffener to see if there's any difference between them. I hadn't thought of gluing on a supporting layer--I'm so used to making bags with only fabric, I sometimes forget that I can use glue. Off to do some experiments with fusing scraps of leather to the Pellon interfacings I already have... -

Introduction And Question About Making Bags

Chopinzee replied to Chopinzee's topic in How Do I Do That?

Thanks fanninator and zikman for the info! I had seen that mention in the Valerie Michael book of "Vileden", and spent a fruitless 20 minutes online trying to figure out what it was. The only thing google came up with was a bunch of stories featuring a "vile den" of thieves... I wonder if maybe Vileden is some version of Vilene (the E.U equivalent of Pellon). "Grey Board" seems to be cover board for bookbinding, from what I can tell--probably too stiff for my purposes, although it could work to reinforce bag bottoms. Zikman, do you have any suggestions for a leather with the right combination of stiffness/thickness? I do have a Tandy's about an hour away that I can shop at if I know what to look for (so far I've been ordering online). They may have bontex too. -

Hi, I'm Hannah and I'm very very new to working with leather! I found this site while doing some internet research about sewing leather bags, and so far I've found a huge amount of info just browsing the old threads. I've made a lot of cloth handbags, but only recently started to sew with leather. I always wanted to work with leather but assumed my sewing machine wouldn't be able to handle it, and I knew I didn't have the budget for a specialty machine. But recently I've been fooling around with a few lighter weight leathers (chrome tanned, 2-3 oz) and as long as I'm careful I can coax my sewing machine to deal with several layers. This has opened a whole new world of possibilities, and I'm excited to start making some leather bags! I recently bought some hand-stitching tools as well, and I'm very interested in learning to hand-sew leather. Here's my question (probably the first of many): when making handbags out of cloth, usually interfacing is ironed on to the fabric to give it body and structure. I've heard that heat plus leather is a Bad Thing, and one shouldn't iron interfacing to it. If that is true, how do bags made of lightweight leather get their structure? Is some kind of material sewn into the bag to reinforce it? If so, what? Is it possible to wrap soft leather around a stiffer frame?