-

Content Count

29 -

Joined

-

Last visited

Posts posted by WoodsideCo

-

-

Awesome thanks Brian!

-Sam

-

On 1/27/2017 at 1:15 PM, cjartist said:I love the look of a round or mexican braid. However using a rotary punch kills my hands and wrists.

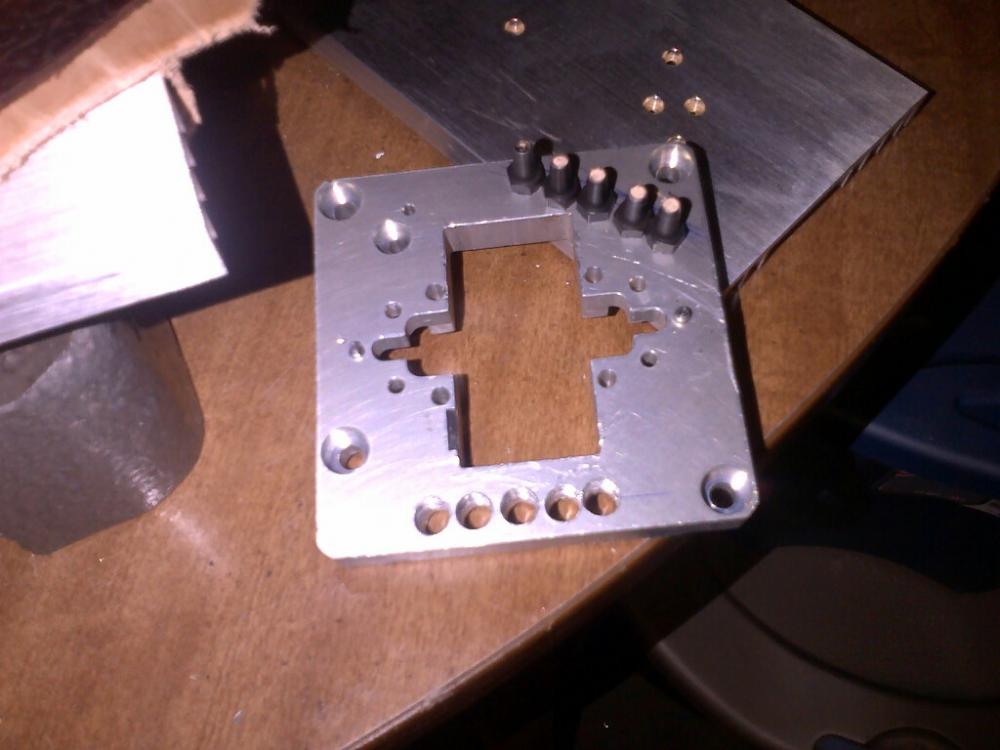

I recently made a seat cover with a mexican braid and punched all the holes over the course of three days. I decided that I needed a better way. So I ordered five of the replacement rotary hole punches, then drilled and tapped a scrap hunk of aluminum to hold them. Now I can use my arbor press for the job. I just punched all the holes for a similar seat cover in an hour and boy, what a difference!

Awesome! What size tap/ thread did you use the for the punches? Are they the osborne rotary punches?

-

Pm sent

-

Thanks guys, I will give Consew a call and see if they can direct me to the closest dealer to me. Really appreciate all the help!

-

1 minute ago, gottaknow said:I can't afford to buy cheap parts. I buy OEM or generic through my main supplier, which sells both. They find the best quality generic and are always up front about quality or issues that have arisen from other customers. It's something we didn't have to deal with 35 years ago. Everything was OEM purchased directly from the manufacturer. I miss the days when the Singer rep would stop by every other week to take my orders. Sigh.

Regards, Eric

Do you know where I could get OEM or generic parts for the Consew 277RFS? Or what the cylinder arm is based on / compatible with?

Thank you, Sam

-

Hey Uwe, That is a good idea. I think I will give that a shot.

Thanks!

-

Hey Guys,

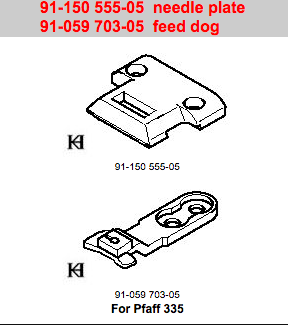

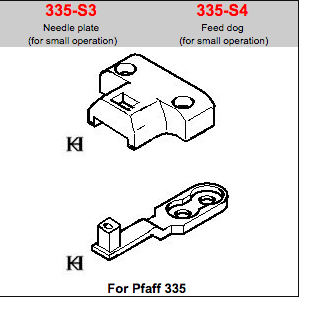

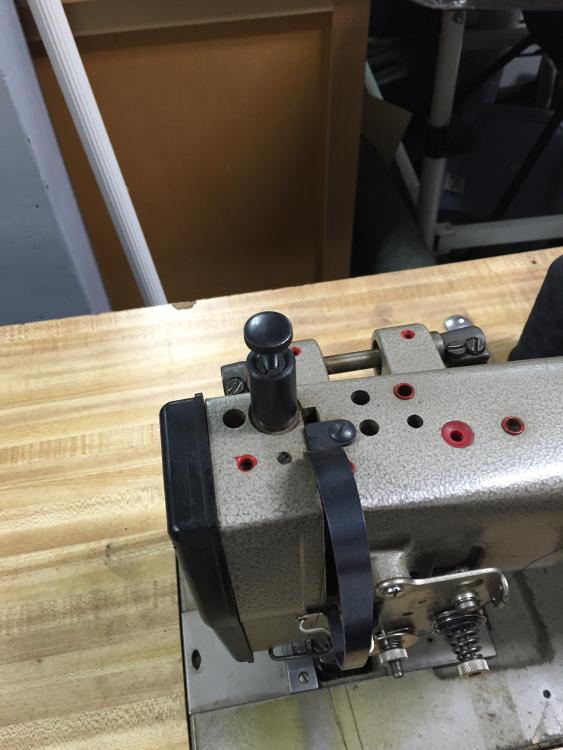

I'm looking for info on the compatibility of Consew 277RFS cylinder arm parts. As far as needle plate, feed dogs, binding plate attachment etc. I understand that all parts are the same as the Seiko LSC 8, but after some searching I cant seem to find what the cylinder arm is based on. It seems very similar to both the Pfaff 335 as well as the Juki 246. Specifically interested in being able to use specialized needle plates, as well as binder attachments for Pfaff 335 on the Consew 277. Such as the attached images available from Kwokhing. I have emailed them asking about compatibility, but have not received a reply. Any information on what the 277 cylinder arm is based on / interchangeable with would be very much appreciated. I have also attached a pic of the badge of of the Consew. Thank you!

-Sam

-

Hey Guys,

I'm on the hunt for a German made Pfaff 335. I am based in the San Francisco Bay Area. I would drive a few hours for pick up or would pay for shipping costs. Thanks!

-Sam

-

PM sent.

-

On 7/17/2016 at 7:53 PM, thefanninator said:Oops... Just noticed I put a 1/2" in there. There is no 1/2 inch, it's a 1 1/4" instead.

Still available?

-

tech sew has this posted as refurbished- http://www.techsew.com/machinery/cutting-skiving-machines/techsew-2020p-bench-top-portable-leather-strap-cutting-machine-used-refurbished.html

hope it helps

-Sam

-

On 9/24/2016 at 4:38 AM, RockyAussie said:Thanks for the tip mikesc. I've had a quick look and can can't find where Tyvek is used in this aplication. EVA foam is a sort of rubbery foam that has a good memory. If you squeeze it, it springs back a bit like rubber thongs do. Does Tyvek behave like this? The application I want it for is as a supple stiffener and padding inside bags and purses and such.

Hey Brian, I think one of these reinforcement options may suit your needs. Possibly the reinforcement GEL, or reinforcement foam http://www.mando.fr/43-renfort

Not sure if you need a log in to view it, if so let me know and i can post a screenshot.

-Sam

-

Nuttish- Thank you for taking the time to write that up. Really awesome. I will report back when I am able to get the supplies you cited and have the time to get everything set up correctly. Thanks again.

-Sam

-

On December 30, 2015 at 0:20 PM, Nuttish said:I forgot to add that bench grinders are ~3500 RPM, which is too fast for burnishing leather IMO.

This is a lot more than you asked, but it's a relatively cheap way to get a more suitable machine burnishing setup and you can continue using your bench grinder as a motor:

Someone at Campbell Randall told me about the merit of burnishing at slower speeds using their various Italian wheels. I use a single phase 1/3 HP motor on a 4:1 pulley connected to an arbor mounted vertically so I can switch wheels out on the top and bottom. In addition to $30 worth of salvaged materials, I needed appropriately sized reducing bushings to fit the wheels to my arbor. I replaced the bearings with babbitt metal. You can get thermally weldable urethane belt material by the foot at McMaster so you don't have to spend hours finding an off the shelf belt.

An easier setup would be a cheap 3 phase fractional horsepower motor and cheap VFD so you can run it on single phase 110 with speed control, which you can't get with a single phase capacitor start motor. This would have been easier to fabricate than my setup because it wouldn't require machining the tensioner/mounting bracket that you can see in the picture. You could make the same thing out of wood with a table saw and router.

Nuttish-

Really like your setup! Are you using the AP style wheels from Campbell? If so where did you find the proper bushing setup? Having a hard time sourcing them for my motor. My arbor is 5/8" and CR's site says that the bore diameter for their wheels is 20mm. I Am looking into getting a bushing setup machined out for me but would prefer to buy something pre-fabbed if possible.

-

Wow fantastic work! Any updates on your machine?

-

Rocky- I dont do enough big runs of belts to justify building the belt edge painter, maybe a single edger though. What did you end up using for the actual paint roller wheels on that machine?

-

On 6/22/2016 at 8:01 PM, RockyAussie said:Hi Johnnywalks, I am sorry that I had not read your entire post on this before. Now I think I see what you are trying to do. I wish I knew what other machinery you have, but what you have here as far as my judgement goes will be fine to do an edge grinding machine. I have attached pics to show how I have made something similar. Mine my look rough but I can move the whole motor up and down to apply pressure in the best place easily.Problem though is that using these type of edge paints in my experience is not much help with these type of wheels other than the 80 grit rubberized wheel. If you get the leather too smooth and shiny the paint will peel of easily. I use these edgings every day and you have to remember that the leather in the first instance needs to be sanded inward toward the middle or the pressure will flair your edges out. After I have finished my bevel sanding I then sometimes mostly on thicker materials like my belts use the grinder to nicely round out the shape. The horsepower of your motor would not be much use for polishing and you would be better to look for about a 2 hp motor for that. I'll cover that in a later post.This motor has a receiving hole that you can make use of the thread. Therefor you only need a flange made up to neatly go over this shaft and shaped a bit like mine shown. Get an engineering shop to lathe it for you and make sure the height allows you to put in the screw and put pressure down.No grub screws needed. One direction it will want to undo so make sure that switch can not be used in the wrong direction.Note the leather piece made up to stop grit getting down into the bearings.If you don't have a small belt sander grinder set up I would be getting this first.The pics showing the soldering iron (light dimmer switch)and the smooth sanding pad and the grey scotch brite material which is the smoothest are some of the most useful tools you could ever want for these type of edging. The workhorse with self made attachments is for doing belt lengths. DAM I hope this is of help.

RockyAussie- Are those wheels you have rigged up to your bench "AP Burnishing wheels"? Campbell Randall sells a few buffing, grinding, polishing wheels that look identical here in the US. I believe they are intended for a few different systems. Ive actually been going back and forth with buying this system http://www.campbell-randall.com/wp-content/uploads/VSB1.pdf which takes those style wheels. I actually have plans sketched out for a very similar bench to accept the wheels without buying the entire vsb system. I've been talking with a buddy of mine who is a machinist to try to tackle a few ideas for edge finishing machinery as I have trouble convincing myself that paying the amount of money some of these manufacturers want is worth it for where I am in production. Maybe in the future, but cant quite justify it yet. I really dig that belt edge painting system you made! I wonder how much money you saved by building yours yourself as opposed to buying something like this http://www.campbell-randall.com/machines/leather-goods-machines/edge-painting-machine/model-991pa-vertical-belt-painting-machine/ or the like. I love seeing guys rigging things together like that either for specific needs that available machinery can't meet or the old "I think I could build that" thought. Good stuff brotha

-

The link was deleted, is this lot still available? Thank you!

-

-

Thanks for the replies on the motors guys, I have a lot to think about. I was wondering what the max thickness of leather is that you have been able to sew consistently is on your 1245's? Also, I was hoping I could get some input on buying one of these pfaff's vs. a new machine under warranty such as the consew 206-rb5, keep in mind this is my first machine. I see positives/negatives of both options, but was wondering if you were buying your first machine and had these options what direction you would go? The way I figure it after I replace the clutch motor, get the machined serviced etc, its going to be within a couple hundred bucks of that new consew, or another newer similar machine. What route do you think I should take?

-

9 minutes ago, Hockeymender said:I have two with speed reducers and two without. Unless you are going to sew some very thick materials, or need to run at a super slooow speed I would say no speed reducer is required. These motors can be set for slow start, just to address the other issue mentioned.

Ok that makes sense. Sorry for all these questions, really appreciate everyone's feedback. About the needle positioner system, once it is installed correctly is it easy to switch from the needle ending in the up position and then back to the needle ending in the down position in the material? Meaning could I do a run of stitching with the positioner in the down position and then flip a switch and have it end in the up position on the next run of stitching? Not sure if that's how these systems work, don't have much experience with them. As far as install is it pretty much plug and play? Would I need to order a different sized belt or does the motor come with a new belt that will fit the 1245? Thanks again!

-Sam

-

Joe, that motor looks very nice and I like that it has the needle positioner on it. Do you think there would be any reason to get a speed reducer with this or should be good to go with just the motor?

Sark- The repair guy in my area stocks and recommended a motor that sounds just like what you've been using. I think he said it was a "family" brand and its 3/4HP with 550 W. He said something similar about feeling like a lot of these motors made in china are almost identical other than the sticker on the front. From what you have said and others as well these seem like a good option, my only concern is the abrupt start. Ive worked on a juki that had a similar type of jump off the line feel to it and it kept throwing me off, I'm sure with a few days of working on it it would not be a problem though.

-

Thanks for all the help fellas, I'm pretty sure I'm going to pull the trigger on one of the 1245's, I'm very excited! Was wondering if anyone had recommendations for a good servo motor (make/model) to replace the clutch motor with? Also do you think a speed reducer is also a good idea with a new servo motor? Appreciate any and all feedback

-

Ok thanks guys, I'm going to try to get my hands on the user manuals for each subclass and see whats what a bit more. Sorry about the pics! cant figure out how to get them to upload upright, Apologies to your necks!

Danny marlin head knife

in Old/Sold

Posted · Report reply

PM sent.