LoveToLearn

Members-

Posts

46 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by LoveToLearn

-

That does not give the right to denigrate others. I wont trade free advice for letting him verbally abuse me for his own self inflation. Having said that nobody seems to agree if that is a start capacitor, or run capacitor, does it have a start switch or does it not, etc. Is it just the cap or is the whole motor a piece of junk to name a few.. Lots of opinions and I appreciate them all. I have to determine who I should listen to and who not to. It says something about folks when they get their feelings hurt when asked for clarification, so much so that they then need to try to make someone else feel small.

-

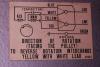

It starts and runs whether its in or if I remove the cap completely and set it on the table. Sometimes it starts clockwise and other times it starts counter clockwise. It is a single phase 1/3hp 3.7 amps 1750 rpm motor. I dont see any centrifugal switch and I hear no click when its winding down when I shut it off like on the table saw in the garage.

-

I took the cover off the back of the motor and removed the capacitor. I put a voltmeter across the terminals with the meter set at 600v ac and got no reading. Then I started the motor with no capacitor and it ran the same as it did before. So the capacitor was doing nothing. I think I need a new cap to tell the motor which way to start. I dont even know if the cap that was in there is the proper cap. I wish I could get some part numbers for the cap and the wearable clutch parts. I would have a good motor then. Then I need a small motor pulley which is 15mm bore and about 35 to 45 mm diameter 3V and a speed reducter which I will make. I have been wondering why guys with the servo motors also add speed reducers? I thought the servo motor provided totall speed control. LoveToLearn

-

Singer 111W-155 I Cant Get Any Bobbin Tension.

LoveToLearn replied to LoveToLearn's topic in Leather Sewing Machines

ya it says nothing about that in the instructions or any manuals Ive seen. Thanks for mentioning that important detail. Ill try it. LoveToLearn -

Adding A Speed Reducer To A Flatbed

LoveToLearn replied to cdthayer's topic in Leather Sewing Machines

Did you notice a remarkable difference in speed and control by changing that pulley? -

Singer 111W1555 Serial Number Year Id

LoveToLearn replied to teched's topic in Leather Sewing Machines

nice quality. thank you very much. !! -

Singer 111W-155 I Cant Get Any Bobbin Tension.

LoveToLearn replied to LoveToLearn's topic in Leather Sewing Machines

Thanks guys, Ill try it. LoveToLearn -

Adding A Speed Reducer To A Flatbed

LoveToLearn replied to cdthayer's topic in Leather Sewing Machines

Thats cool but where are you guys finding the tiny pulley for the motor? I have a Consew clutch motor with a 15mm keyed shaft and I can find nothing for it. I woud like a 35mm pulley with 15mm bore. The machine is a singer 111w-155 which i think the handwheel pullley is 3V. Any ideas where I can locate one of these mythical creatures? If it doesnt slow it down enough that way, Ill add a speed reducer. I already have an idea how to make one inexpensively. -

Im looking at the pedal travel and when I push the pedal down I can see something that looks like a disk brake rotor and a brake shoe. There is an adjustment screw that looks like it sets the travel of this shoe. On the other side of the rotor looks like some kind of wheel that engages by means of friction with the brake rotor thing. What is this and what is the proper adjustment? Also are there any replacement parts for these clutch motors? This one is a Consew motor 1/3hp 1750 rpm. My goal is to have my machine up and running by the end of the week so I can start learning how to sew. Thanks LoveToLearn

-

I recently bought my first machine. It came with a nice K Leg table. The top is perfect but the green plastic molding that goes around the perimeter of the table is missing. There is a slot in the table edge where this trim goes. There is some of it remaining, about 3 feet or so. Do you know where I can buy one? Its a crazy story what happened. I bought a lathe a few years ago on craigslist. When I went to get it, it was attached to an industiral sewing machine table, with green top and the plastic molding was perfect. Of course I didnt need it so I took the lathe off put it on the workbench that I built for it and disassmbled the table and put it away. I didnt use it for years. I always thought though that maybe I would get a sewing machine and use the table. As time went by , I wanted to get rid of stuff I never use and rationalized that if I ever got a machine it would come with a table and I wouldnt need this one. Besides who knows what kind of machine this table fits and the chances that it would be the one I want is slim. So recently, very recently I set the table top on the curb for pickup and as I looked back at it one last time I considered taking the molding off because it looked like something that would be hard to find. Finallly I told myself, quit holding on to everything, just let it go and maybe someone is looking for that molding and can use it and be happy when they find it on the curb. So I let it go. Sure enough, weeks later after never needing it for years, I buy a nice deal on craigslist for the SInger 111w-155 with table and everything and I mean everything, everything except the green plastic molding that goes around the table. I means statistically what are the chances of this? Is this Murphys law or something? This happens all the time. The moment you throw something away, you need it badly. So, does anyone know where I can get the molding for this table? Thanks LoveToLearn

-

Ok will do Cowboy. Are bigger handwheel pulleys available also? Right now the pulleys look about equal in size. If I had a 2" motor pulley and 6" handwheel pulley thats 3:1 so my 1750 motor would be turning the machine at 583. I wonder how many stitches per minute that is. Is this doable? I thought about a speed reducer by they are a bit pricey and it looks like you have to move the motor mounts or the sewing machine so it is offset so the reducer pulley lines up with the handwheel pulley. Not sure I want to remount the motor an inch over. I cant see how else that would work. Thanks LoveToLearn

-

thank you Wiz. Now should I keep the 66 or the 500a rocket? The rocket is more versatile with all the stitches it can do. The singer is older and very cool indeed to behold. Both are portable. The 500a is much lighter and smaller and I think is worth more because it has a cult following it seems. The 66 is simpler. 500a has more that can go wrong. What to do.