-

Content Count

28 -

Joined

-

Last visited

Posts posted by medion

-

-

I'm also noticing something else which is contributing to inconsistency - thread spooling off my thread cones is not smooth. I can feel it jerk, especially as it spools off the bottom, as if there is a minor stickiness factor in the cone thread. Is this a result of a bad batch of thread? Or?

-

Thank you everyone for your help - so, for future people having this issue, it seems like an increase in needle sized has likely resolved it in tests. I need to run a few actual wallets now, however, with scrap it looks like it's resolved. I'm running M40 thread needle 130/21

-

This actually looks like it's not an entirely uncommon problem

-

17 hours ago, RockyAussie said:I am thinking that after you lift the presser foot you are at the same time having the tension discs open up which then do not come fully closed as quickly as they should. Try and see if there is something catching the little rods that opens the discs or the rod that pushes the plate that opens them. Might just need a bit of oil.On the other side of the machine check if the parts that push that little rod are not moving as freely as they should as well. If all this gives you no joy....try lifting out your needle until only the tip is in place then only partly lift the presser foot and then do your turn. If you have the needle positioner on your machine you may have to disable it first.

Thanks, I'll take a look! Honestly, I have so many tension issues with this machine, none of my other 3 machines cause me so much drama... I feel like I'm constantly fixing a hangup or battling a bizarre issue like this...

-

2 hours ago, Wizcrafts said:The problem could be caused by twisty thread (top and/or bobbin), or a change in the density of the leather as you round the corner, or the glue/tape you baste them with, or the needle point shape, or the foot pressure, or by the setting of the check spring.

Obviously, the tension has changed after turning that corner. Try reversing the direction of the bobbin and adjust the tension to balance the knots. Run a little higher overall tension to make it easier to position the knots.

Try to watch the leather as you round the corner to see if it lifts with the needle. More foot pressure would subdue that problem.

Try a different needle with a different point. A diamond, or triangle point may help.

Use titanium coated needles and keep a dauber and Goof Off handy if you sew through leather tape or heavy cement.

Thanks very much for all these ideas - I will try swapping in a new needle to start with and see how I go. With regards to twisting thread, I wonder if the thread is twisting when I round the corner? My corner rounding is done by spinning the wheel by hand, as I cannot reliably control the clutch and round the corner. So, I sew up to the corner, stop, hand crank and turn the corner with the needle down and the foot up. This is how I've always done it, and I've rounded literally hundreds of corners on hundreds of wallets and other objects, but for some insane reason this is now plaguing me... Anyway, let me try a needle change and changing the bobbin direction. Thanks again.

-

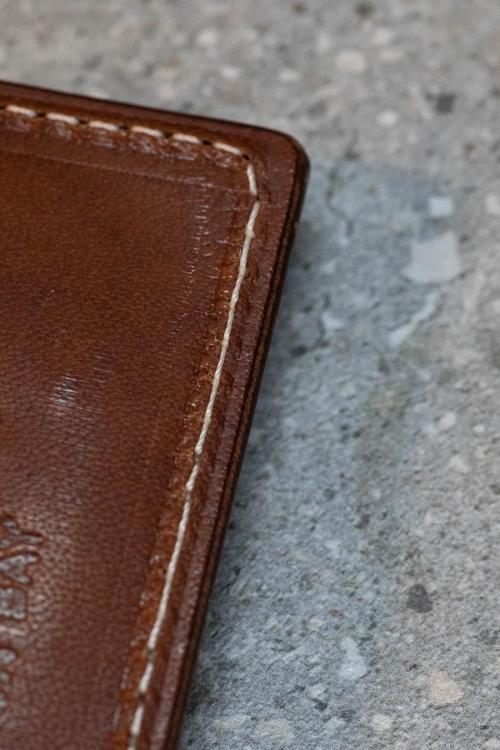

Hi all,

I'm working on 10 wallets and 3 of them are having the strangest loss of bobbin-tension after rounding the corner. I cannot work out what's going on, and I've re-worked two of them hand-winding through the existing holes, to the same effect. I cannot for the life of me work out why this is happening. It's on a JUKI 1508 NH - any thoughts on what's going on would be so very helpful!

Cheers, Medion.

-

13 hours ago, Matt S said:Quote@medion, is there any particular reason that you're using v69 thread? Unless you have a very particular reason for using exotic thread you will probably find that using a thicker nylon, polyester or linen thread will give you more strength than you need. V69, for instance, is something I only use on light duty items like pocket notebooks and wallet internals

The honest truth, is that I like working with unusual and high performance materials... There is no reason other than that

I do currently use v69 right throughout my wallets though, it has held up well so far - what are you using for your main wallet stitch line if only using v69 for wallet internals?

The honest truth, is that I like working with unusual and high performance materials... There is no reason other than that

I do currently use v69 right throughout my wallets though, it has held up well so far - what are you using for your main wallet stitch line if only using v69 for wallet internals?

-

Hi all,

Does anyone have any input on what could be considered the strongest modern machine sewable thread for leather? I currently use a bonded nylon #69 thread which is fine, but I do wonder what the strongest machine sewable thread may be, I'm thinking in terms of Kevlar and Dyneema (or others?) - does anyone have experience with high tech threads? I understand there comes a point where the thread is significantly stronger than the leather, however I'm wanting to avoid that part of the discussion.

-p

-

THANK YOU everyone - you're all right, it is the clutch being in brake mode when the machine is stopped. If I run the pedal very lightly, the stiffness disappears - thanks so much, I was getting all worried about having to fit a new motor or something

-

Hi all,

I have a Pfaff 335 - the older style, image attached as an example.

I'm having an issue which appears to be getting worse, whereby the motor is hard to turn/sticks. It's not the machine, if I take the belt off the machine itself turns over smoothly. That being said, the clutch/motor still works perfectly fine, and you wouldn't notice it if you didn't hand crank the needle into position or around tight spots.

I'm just wondering if this is normal behaviour/the motor is wearing out/bearings are toast/or other. Am I not doing something maintenance-wise? My other two machines are much newer with servo motors so I have nothing to compare - I also live in a remote place without access to industrial machine mechanics.

Any help greatly appreciated!

Cheers!

-

5 hours ago, dfrensdorff said:Medion...... I do have the smooth presser door and walking foot as well. I do recommend you get those, or sand/carefully grind what you have. They are relatively inexpensive from Toledo Sewing. Even so, you still may get some foot marks, but in my experience, nothing that a bone creaser can’t smooth out. Keep messing with your foot pressure.

Cheers - sorry to be a pain, but are you able to show me a link to the bits you changed on your machine?

-

51 minutes ago, dfrensdorff said:I have the exact model Juki, and sew everything from wallets & belts to chaps, chinks, and Dopp kits. I also go from waxed canvas to leather with minor adjustments. 92 thread is what I use most for wallets, but it is easy to go from 92-138 thread. As you know, you’ve got a great machine there. Get needles from Bob at Toledo ..... good luck!

Ohhh, please tell me what changes you've made to your machine since we have the same one!

I've tried loosening off the presser foot just now, and I'm still having a track issue, particularly on the shiny side. Did you do the aforementioned sanding mod on the feed dog?

I've tried loosening off the presser foot just now, and I'm still having a track issue, particularly on the shiny side. Did you do the aforementioned sanding mod on the feed dog?

-

9 minutes ago, CowboyBob said:You can loosen the pressure on the foot & buff(sand) the feed dog,a smaller pulley will help slow it down.Here's a needle & thread charthttp://www.tolindsewmach.com/thread-chart.html

Thanks, I will try re-adjusting the foot and buy another feed dog to sand down.

Regarding thread size on your chart, I have a lot of 69 (T70) [Tkt 40] - is this strong enough for wallets or should I move up to my original idea of 138 (T135) [Tkt 20] ?

-

Hi all,

I have a Juki 1508 (1508NH specifically) that I am now experimenting with for production wallet sewing. This machine, along with my others, have primarily been used for canvas work and I'm very inexperienced with leather sewing. I pulled out some leather scraps yesterday and now understand it's going to be quite a bit of fiddling to get a nice finish! I was hoping I could get some advice on some immediate issues - I have no access to a machine mechanic because of where I live unfortunately, however this machine will be dedicated to this one task, so it can be tweaked for its purpose.

- The presser foot & feed dog are leaving tracks along my leather. Can the presser foot be replaced with something made of nylon? Are there special 'leather feed dogs' which have less aggressive teeth, or is it all about tension and adjustment?

- I'd like to use M20 nylon bonded thread - what is a leather point needle recommendation for this thread size?

- I need to slow the machine right down (clutch motor) - is a smaller pulley the way to go or must I get one of the more specific speed reducing pulleys which also gear the machine for torque? The Nick-O Sew dual speed reducers on eBay are nice, but after USD conversion and shipping to Australia it's an expensive bit of gear.

Thanks so much!

-m

-

Hi all,

I've recently picked up a Pfaff 335 which features a synchronised binder - I have a 14mm shell, but I'm after a 19mm or 20mm shell for this machine, but I can't seem to find one anywhere. Is anyone experienced with these machines, or know of any stores which sell a range of shells for them? Cheers, -M

-

I ended up finding a Juki 1508, only used for 6 months, shipped to my city for $1600USD, so pretty happy with the outcome in the end!

-

The SInger 132k6 is made to sew buffing wheels and webbing, up to 1/2 inch thick, with #346 thread, using a #26 needle. It seems to be a good match for your projects. I used to own one of these beasts and know its limitations and advantages.

As for reverse, you can either spin the work around to backstitch, or just sew over the starting thread for a few stitches. I have a SInger walking foot machine without reverse and overstitch all the time. Four or five stitches should do the trick.

With the Singer, are parts and accessories like binding attachments readily available? If in future I like the machine, could I upgrade it to a servo motor?

Also, I have stumbled across many of your other related posts (they constantly come up in Google when researching machines!) - thanks for putting up so much valuable info.

-

Thanks for the feedback! Wouldn't you know it, the Juki has been for sale for two months, and sold yesterday!

Any thoughts on the Singer 132K6 as an alternative? My only concern with this era of machine is lack of reverse.

-

Hi all,

I am overworking my Juki DDL-555, sewing through multiple layers of canvas, leather, seat belt webbing, and other materials it wasn't really designed for. Therefore I'm looking at a walking foot, and the Pfaff 1245, Juki 563 are available nearish to where I live.

The Pfaff can be upgraded to a servo motor and would come in at around $1100USD, the Juki around $680USD with a clutch motor. They are both gold/bronze coloured, so built in the 80s sometime. Are these machines overpriced? Any other machines I could be looking at? Availability is always the issue, ie. Consew 206's aren't anywhere to be seen.

The alternative could be to keep waiting for something else to popup, or to consider something new, like a Cowboy or Typical Chinese machine...

The materials I'm sewing, are 3-4 layers of webbing, leather strapping, multiple layers of canvas and wool with binding, etc. I unfortunately do not think I can afford a newer machine like the Juki 1508.

I also have a bunch of binding attachments for my Juki 555, but I have a suspicion none of them will fit the aforementioned walking foot machines, which is a shame! Are attachments for the Pfaff readily available?

-

Just an update: I ended up getting a mechanic in to look at my machine. He actually got it working reliably by removing bits: We removed the knives, as they were having issues cutting the high tensile nylon bonded thread I'm using. We also removed the lower thread retainer.

The mechanic additionally adjusted the bobbin thread, and this made a very visible difference in stitch quality. The machine is now reliably stitching, the only draw back is I need to cut between stitches - no big deal, as I don't run a production factory. Also loosening up the thread on the tensioner improved the stitch - I'm now able to punch through three and even four layers of webbing.

Just posting this for any other antiquarians who are interested in getting the Singer 269W / 269W141 going.

All in all pretty happy with my $150 bartacker!

-

Amazing, thanks everyone - such fast replies! Kaplan Sewing link was great, thank you.

Has anyone ever worked in high load safety sling sewing? Ie. lifting slings, vehicle lifting slings, etc - and if so, did you work within standards set about by your country? For example, in Australia we have things like the AS/NZS 4380:2001 standards - Cargo restraint systems -Transport webbing and components. Does anyone have any feedback on the reality of working in this kind of industry?

-

Does anyone recognise what kind of machine this might be?

-

That stitch looks pretty good to me, considering you're sewing webbing!

That document I mentioned has info on setting the hook timing - although it says "parts list" it has more than that in it. I had a quick look as I was curious (it's different to my machine). I can't help with the cutter, as I'm not familiar with them, although mine had an automatic cutter which cut the excess material from the seam as it was sewed - I removed it as 1) I didn't need it and 2) it was one more complication I could do without!

As long as the machine is working mechanically, virtually all problems, in my experience, will be due to thread tension and/or hook timing. Spend the time to make sure the hook timing is correct,

Yes, not bad! It is quite fickle though - if I change the webbing type I have to start my thread tension adjustments again to try and get it working. But it is what it is!

For the hooking timing - do you mean the section on 'To time the shuttle' or 'To time the cam feed' ? I can't see a reference to hook timing per se in that PDF.

-

I've actually managed to get the old thing working quite nicely - looks like it was primarily to do with tension, although on the odd tack it still does mis-cut my thread, I will need to work on that issue another day: https://www.dropbox.com/s/bow03zjpqkc1ya8/Photo%208-09-2015%2011%2008%2049%20am.jpg?dl=0

Cotton yarn for blanket stitch machine

in Leather Sewing Machines

Posted · Report reply

Hi all,

This is a bit off topic as it's not a leather machine per se (this is my only non-leather sewing machine), however I know there is a wealth of knowledge and industry here and I was hoping someone might have an answer.

Does anyone own a dedicated blanket stitch / crochet stitch machine - most commonly built by Merrow? I own one for whipping blanket edges. I currently use a 5/2 weight cotton yarn for this, however I am noticing the yarn I use often has knots in it, which is ripping through my needles. Has anyone worked with these machines and able to recommend what kind of yarn/brand/weight is commonly used in production blanket edge stitching?

Cheers! Medion