-

Posts

26 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Svey302

-

Good morning, I was trying to use a magnetic seam guide to align my sew line. The cover plate over the bobbin, keeps sliding right preventing the guide from doing its job. Something is obviously missing to lock the cover place, what I am looking for? Looking at the drawing, I think it is part 893 06 820 7 ZYL. SCHR. M3X3. What could I find to replace that part? or is that part available somewhere? Tx Yves

-

Good day, I have installed the servo motor in the picture but I am a bit confused with the set of instruction. There is 2 type of gesture or action possible. "Press" which I think I understand. Then "Flip" which I don't understand what I should do. I don't know if anybody else as a similar motor or experience with one, I would like to understand. At the moment, I can set the speed and use the machine but that is about it. Tx Yves Manual1_1676377433902.pdf

-

I brought the machine home yesterday. The belt is a rubber toothed one. Not cotton. I have cleaned the metal base and table, dusted and oiled as best as I can understand the oiling schematic. The drawing of the under carriage are not the best. I have wound a bobbin with white V69 and threaded the top with black V69. I have ran a few hundred stitches of various length in some pig skin 4 ounces. I forgot to take pictures before leaving home this morning. It came with 2 motors, the original one (clutched) and a small Vevor servo one, both in boxes. I have installed the Vevor one. I need to find some user manual on the motor, there is a digital readout but I don't know what it does. I think I will have an experienced service technician come by to adjust and time the machine. And to learn what to oil correctly. Tx to everybody who shared their experience and opinion. Yves

-

Tx for your recommendation but as they say, you never get a second chance to make a good first impression...I am talking about Raphael/Techsew.

-

Thank you, I will take a look. I will probably pass if it is the cotton string.

-

Thank you CowboyBob, I will be going later today. Is it easy to locate once the machine is lifted?

-

Hello, Tx for your input. I have the room, I haven't picked up any sewing machine yet. Still manually stitching only. I have the name of the service tech working on my friend's machine, I will call him tomorrow to see if he can work on that machine. I think it is better to move the machine to my place before have it serviced/timed, not sure what is the proper term. Yves

-

Good day, A friend who owns a shop making EMT bags is offering me an adler 67-gk373. The machine has been collecting dust for 4 to 5 years, he got it in a lot because he wanted the clickers. Would it be a smart thing to bring the machine home or the machine is just too old to be worth the trouble? I would be moving the machine myself as soon as my trailer is free from the snow, so no moving expenses. Tx for your input, Yves

-

Following advices from more experienced members, I am now looking for a cylinder arm machine. I have spoken to Techsew, the 2750 is 4k cdn. I am thinking about it. Mostly because I will need to save another 2k to purchase it. This one has come up for sale locally for 980$ cdn Pfaff 345 From the seller: the machine is in good order of working just be serviced and the shuttle hook is new...i doing bags canvas, pvc ,cordura ,and webbing she's set with NM 130 needle and nylon thread 69 ...the Bobin can't take more than 138 threads so you can't saw leathers thicker 3/16 . Even if I have never sewn leather by machine before, I think the 3/16 max thickness is not enough.

-

Tx KGG, Your suggestion makes perfect sense. I will try to see one working locally. Yves

-

My needs/wants : that is a difficult question. At the moment, I am only assembling leather by hand (saddle stitching). I would like to explore something else. Wallets, belts, messenger bags. I also own a 2 sailboats so I could also do my canvas work (at the moment, we have an old juki at the yacht club that I can use.)

-

Tx kgg, I am leaning in the same direction you are sugesting. Yves

-

Good day, I have been looking for a while to get a walking foot sewing machine suitable for leatherwork. This machine which I believe is either a clone or rebranded of the Juki 563 is for sale in my region (Montreal, Canada) for a 695$ cdn. From the worn paint, the machine looks well used, I went to see it work with some sample of leather is use for hand sewing. Should I pass on that machine and spend a little more at a local used sewing machine shops? or go with this machine and hope for the best? Tx for any input. Yves

-

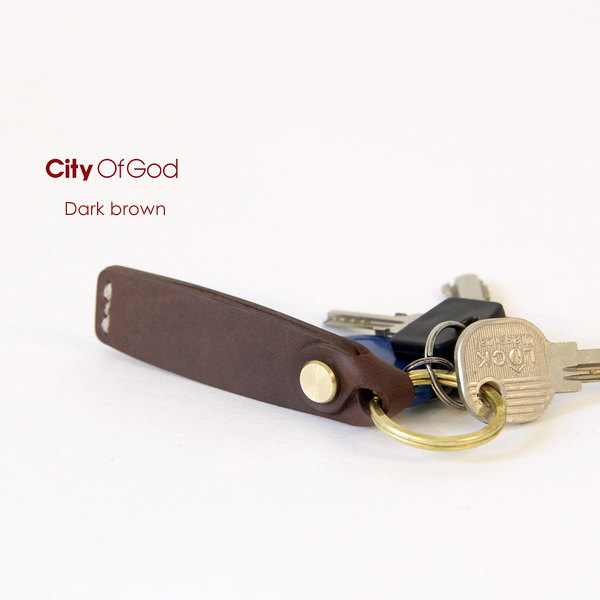

4th prototype, 1st made in leather. I need to refine my edge finishing on the round ears. Tx for everyone's help, Yves

-

I have been playing with the designs suggested previously, shortening the neck. Seeing Monicaj origami help me understood, finally. For some weird reason, I assumed that the ears were crossing (left to right, right to left). I will refine my pattern and built a few prototype to refine the keyfob. I will work with Northmount's design. NVLeatherWorx makes a good point about optimizing leather usage. I appreciated all the help I received. Merci, Yves keyfob shorter neck.pdf

-

I have tried with both design suggestions a couple of time but I must be doing something incorrectly because I am not seeing it. If you haven't discarded them already NVLeatherWorx, could you take a picture of your trial? Truth be told, my problem could be that I haven't got enough leather under my belt to tackle this project. Tx for your help, Yves

-

Thank you, I have tried both design. I did not think of using a thicker leather to get a smoother loop over. I will try that tonight. Tx Yves

-

Hopefully Thor, I soon as I sober up, I should be able to figure it out.

-

It similar to where I was going, I had the antenna/tab crossing more like an X. I will printout your suggestion and play with it. Thank you.

-

Well Tony, if you do I will buy one from you!!! In the mean time, I am cutting individual pieces as I see them and I will assembled them with a hotglue gun, I should be able to figure it out before the new year.

-

You are 100% correct, they go for 20$ usd but they are sold out. That would have been my first intention.

-

Roq, I am sorry, I must be thick (I am from Canada, so I can't even pretend I had to much to eat/drink yesterday). I have printed your suggestion, I am trying to fold the piece with the "antenna" but I don't get it. I still think it is made from one piece of leather. I have included a front and back pics.

-

I did a search for Tboice but did not come up with anything. Can you make it a url link? I could browse his wall. Tx

-

Good day, Relatively new to leather working. I saw this key chain that I like because it is made from one piece of leather (I think). I am trying to come up with a similar version on paper but I have a hard time coming up with the solution. Looking at the pictures, I think that the 2 main rectangular portions should be at some angle to one another (45-60 degrees). I must be missing something to come up with a working pattern. Any suggestion(s)? Tx Yves

-

Thank you Bruce for your advice. For the top roller, I think your ultimate suggestion to make it smooth makes perfect sense, I have played with tension and in order for the leather to feed, it still leave mark but a few passes with the burnisher smooths most of the mark out. I wrapped a couple "lobster claw" elastics around it, that eliminated the marks completely. I have been trying different blade angles, I did take apart and lube everything so the blade moves well. The spring tension was initially set to its maximum setting, your suggestion of lowering that pressure made everything a lot better. I was able to get a skive of 3/4" but I still get a scallop edge on it. But that could be from some gear being worn out. Yves