stor

-

Content Count

21 -

Joined

-

Last visited

Posts posted by stor

-

-

-

My Juki lu 563 is coming along, change the hook to get it to accept a thicker thread in the bobbin and the new servo is doing a good job with my speed reducer, however, i got another problem.

I would like to free up my right hand when i do reverse stitching and my question is !

Is there a way to disable the spring on the reverse lever so i don't need to press it down while I'm stitching reverse?

/P -

6 minutes ago, jimi said:Thanks Stor, that looks good and slow. I have had this on my list for a while now also, maybe get around to doing it one day. the jack is also a little too fast for me.

No worries !

Maby one of the guys above can point you in the direction of a seller if you dont wanna go thru the pain of 3d printing one, but if you do wanna 3d print one let me know and ill send you the file. -

12 hours ago, chrisash said:Nylon may be a better long term filament as stronger and often used in gears etc, now he has the STL file made for the printer just a few hours printing to use another filament

yes, thats the plan now when i know it works.

-

On 3/13/2019 at 10:28 PM, jimi said:Hi Stor, yes could you post a video of the speed

Slowest i could run on the slowest speed (500)

The knocking sound is the hook hitting the needle, i just switched my hook (B1830-563-BA0) to get thicker thread at the bottom and i need to adjust the distance from hook to needle. sorting it out tomorrow. -

15 hours ago, dikman said:If you search on ebay for "45mm pulley" they're around $3-4.

6 hours ago, katit said:$3-4 shipped from China. Just ordered one yesterday. But I guess it's part of fun to DIY

I do lot's of things that don't make any financial sense..

I do lot's of things that don't make any financial sense..

I did find alot of 40-45 mm pulley but none that fit my 13 mm axel that my Jack have and i guess i could have spent more time to trying to find the right one but in the spirit of DIY whats the fun in that ?

i learned 2 new skills and hopefully inspiring someone in the process.

i learned 2 new skills and hopefully inspiring someone in the process.

I keep you posted on the progress. -

Thanks !

i was around for the original run of MacGyver !

Printed it in PLA as test, see how it holds up, where not sure it would work at all and my backup plan was to do a speed reducer with a large and small pulley.

/P2 minutes ago, jimi said:Hi Stor, yes could you post a video of the speed

i sort it out tomorrow.

-

I got a Juki lu-563 and as soon as i got it i took the old clutch motor out and now i use it as a boat anchor

I invested in a Jack JK-563A-1 servo motor and its nice ! However ! its abit to fast for me even at its slower speed and when i did some digging around i found that i wasn't the only one with that problem and tried to find a good solution for it without spending 2-300 euros on top of that and i figured a smaller pulley would do the trick but couldn't find any 40 mm pully for it.

After some brainstorming i figured I just make a 3d model of what i needed and hired a 3d printer owner to print it for me and it arrived today, i needed to drill out the hole and do some file work to get it to fit and now it installed.

and it arrived today, i needed to drill out the hole and do some file work to get it to fit and now it installed.

I printed it in PLA as a test and gonna run in until it falls apart but im surprised that it works so well !

im totally happy with the speed now, i can do a recording if anyone wanna see the speed.

Here is a few photos

Kind regards

Peter - Antfarm steel & leather -

On 1/6/2019 at 12:55 AM, Wizcrafts said:Did you back off the bobbin spring tension screw? The bobbin tension shouldn't be so tight that the top tension causes the thread to snap as it goes around the bobbin case/shuttle. Too much bottom tension needs to be offset by excessive top tension. This causes the thread to dig in more. Back off both tensions and rebalance the knots.

Thank you ! that fixed it and i went with a smaller needle aswell to get less blowout.

/P -

5 hours ago, Wizcrafts said:If the knots or loops are constantly showing on the bottom, back off the bobbin tension spring a half turn at a time until they are centered in the leather. If the knots always show on one side or the other, the thread is too large for the thickness being sewn. In that case you need to use a smaller thread on the bottom, or on both sides, along with a smaller needle.

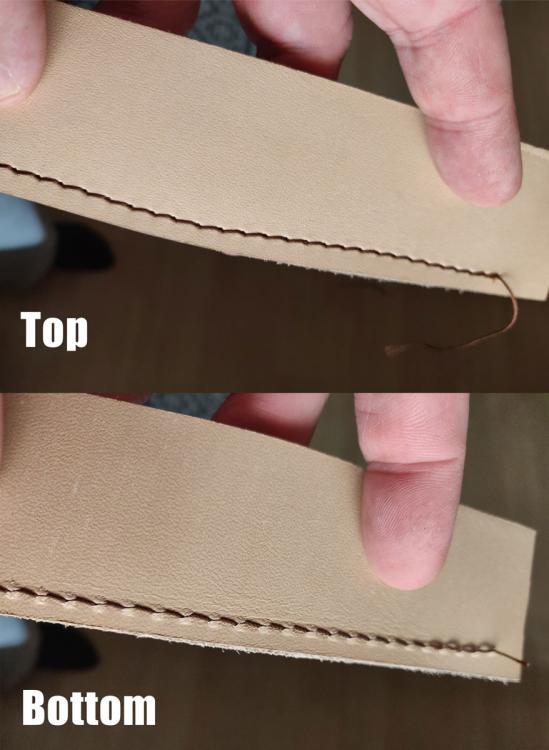

the problem isn't the knot, the problem is that the bottom stitch is tighter and digs into the leather more than the top stitch.

14 hours ago, ensitmike said:I had a similar looking bottom stitch. Switching to a diamond point leather needle cleaned up the stitch a lot.

Was this by chance stitched with a standard needle?

Looked a lot worse with a TRI needle, using a RTW now, couldn't find any S.

-

My top stitches look great but bottom stitch is to tight and cuts into my leather when I loosen the top stitch nothing really happens except that the loop shows up in the bottom.

Or maybe I'm using the wrong size needle?

Or am i just being picky about how it looks?

Using a Juki lu-563 - #15 thread and size 160 needle -

Any proper 3d application like 3d studio max or Maya can extrude a black and white image and apply it to a cylinder they way you want.

-

Thanks Jimi i will try that !

-

-

2 hours ago, Wizcrafts said:No.

Thanks

-

I have a singer 29k8, is it possible to upgrade bobbin size from small to big ?

-

5 hours ago, shoepatcher said:Stor,

the part number is SS535. College sewing in the UK carries the part. I think it is $2.35 pounds. It is a clone piece but should work.

Glenn

Thank you so much !

Notest i was missing the Oil cup spring aswell ordered them both.

Whats the thickest thread / needle i can use on my 29k ? -

On 2017-07-24 at 2:52 AM, shoepatcher said:Finally found my 1900 29K parts list. The 29K8 was set up to sew waxed thread. It had a heavier tension spring on top and in the bobbin case to handle the thicker thread. It also had a different throat plate. Other than that, same as the 29K1. By the way, your machine is missing the stop screw in front to lock the feed foot as to direction!

glenn

Any chance you can scan it and post it here Glenn ? Would love to see if i can find the missing part aswell.

Thank you so much for taking the time to look for it !/Stor

On 2017-07-17 at 9:06 PM, Constabulary said:Nice setup and well displayed! There are Singer crazy people out there who would kill for one of these stools - thats what I´ve heard

This made me do some research and and its crasy how much they go for

-

4 hours ago, Uwe said:Congratulations on finding such a great deal on such a beautiful machine. LOVE that stool, too!

Thank you

3 hours ago, shoepatcher said:

3 hours ago, shoepatcher said:Stor,

I have and original parts list for the early 29K's from 1900. Let me see what it say about the 29K8. We know it was built at the Kilbowie plant.

glenn

Thank you for taking the time, i appreciate it very much !

2 hours ago, jimi said:Aye, Bonnie Scotland!! good picking Stor! I found this on a forum...don´t ask me where they got it from

I found this on a forum...don´t ask me where they got it from 29K & 29U Subclass Listing

29K & 29U Subclass Listing

29- (class) Industrial Universal feed arm (rotates 360 degrees). Upper feed

only (MOST models). Arm lengths: short = 12 1/4", long = 17 1/2".

Hand or treadle powered. Horizontal oscillating shuttle. For patching boots and other Tubular Work

29K8 Arm 12 1/4" x 1 1/8", small bobbin, end wheel.

Needle 29x3 (leather), 29x4 (cloth)

Thank you so much for sharing and taking the time, this is a good start.

-

First of all let me thank all of you that make the effort to share information on this forum, been a huge help while i started leatherworking !

So finally i got my hands on a singer 29k, its a 29k8 and according to the serial its made 1897 so happy 120 year birthday

Its been served and a few years ago and no one have used it after that so all i needed to do was to feed it some oil, everything runs smoothly and im looking foreword to learn to work with her.

I got it for 200€ and a nice bonus was that i also got the original stool with the singer.

Done fair amount of research but cant really find much information about 29k8, closest i got has been in a few manuals that have 29k73, anyone have any information to share about 29k8 ?

Here is a few pics

/stor

Juki lu 563 - foot gettign stuck in up position

in Leather Sewing Machines

Posted · Report reply

Got a problem with my foot getting stuck in up positionen, i need to push it down after i lift the foot

I have oiled all parts but cant figure out where it getting stuck.

https://vimeo.com/337160562

/Stor