-

Posts

49 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by JeffHami

-

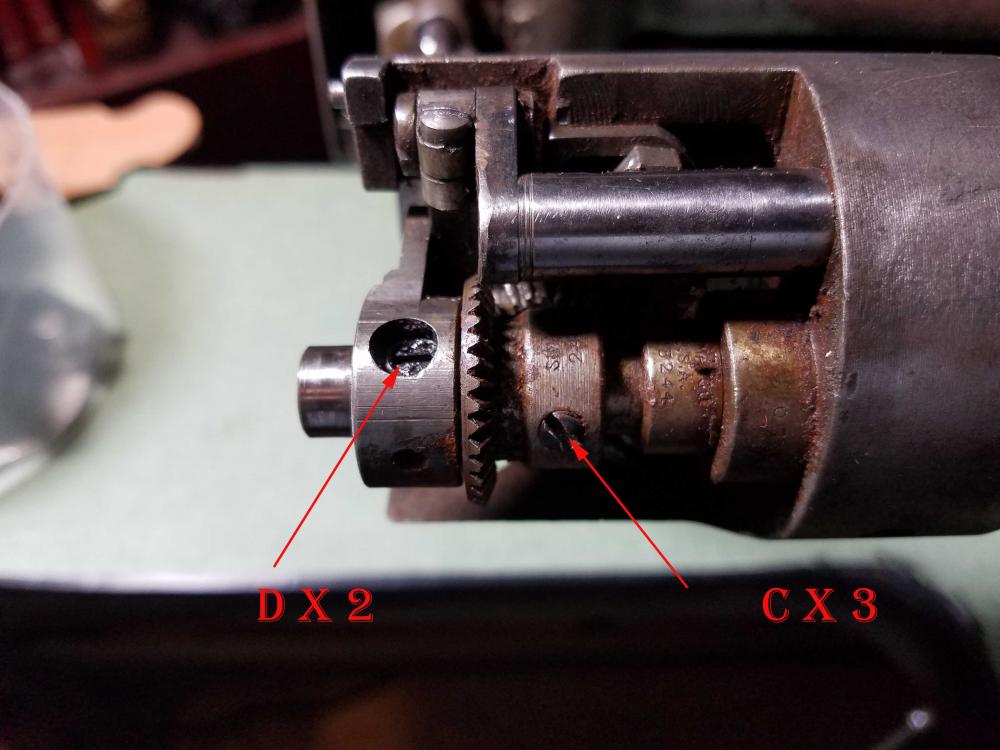

I had already loosened the 3 set screws that the arrow is pointing at so that is why it looks long. Does the beveled gear on the bobbin assembly wear out?

-

-

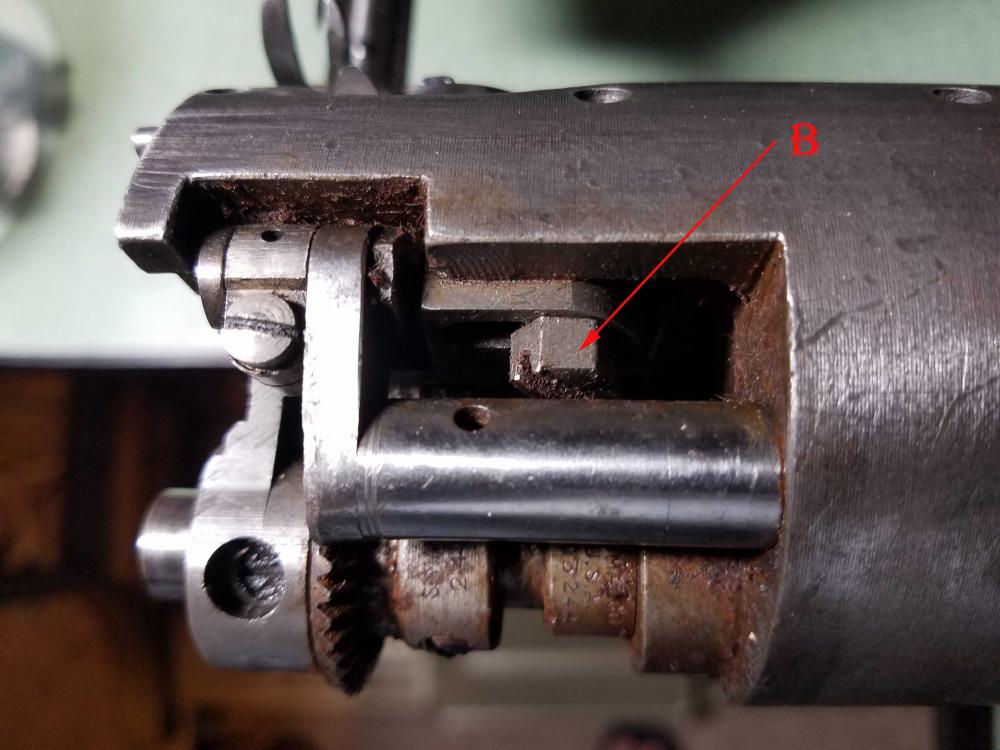

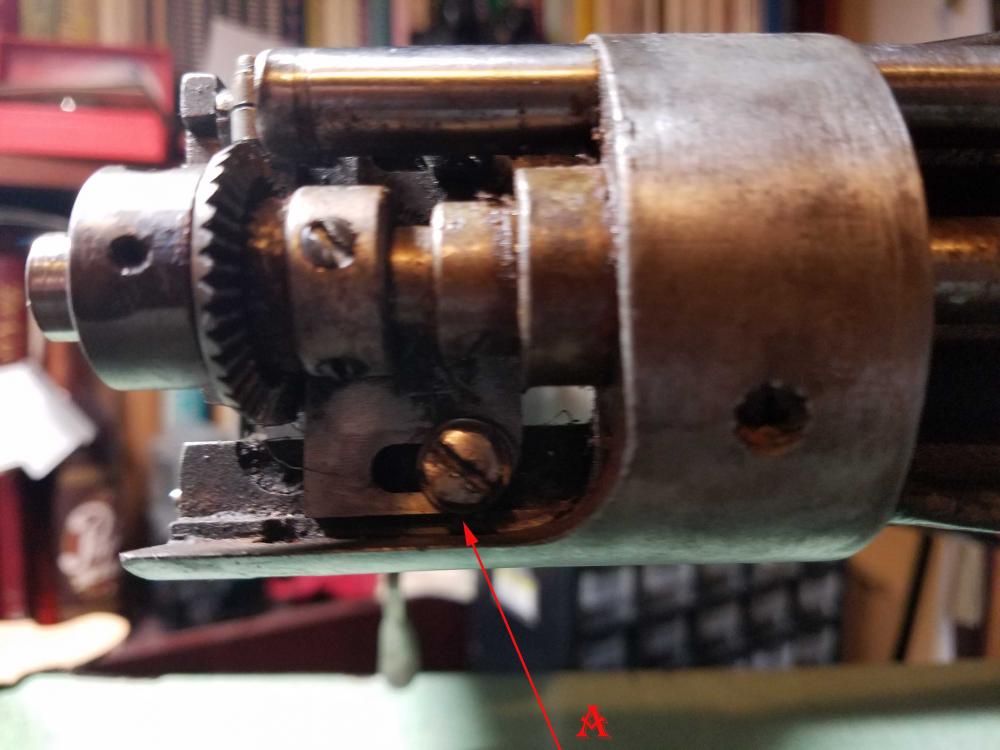

Was sewing on my Singer 153W when everything went to pot. It appears something slipped and the timing is all wack. The first problem I noticed is the pickup hook is now hitting the bottom of the feed dog. I went through and tried to make adjustments but the hook's beveled pinion does not want to stay engaged with the beveled pinion on the shaft. If I move it close enough for a better mesh the pickup hook of the bobbin strikes the needle. I tried loosed screws C and D and tapping on the gear but it does not want to move. I also have a problem with screw B of the bobbin assembly not able to tighten but screw A will . Any advice on how to solve them would be greatly appreciated. I hope I have give enough info.

-

Thanks, can't wait to have time to use it.

-

I picked up this Singer 153W100 at a yardsale and I have been working on getting it back into good working order. I want to thank the folks on the forum for all their help and support. I must admit there was a lot of time and elbow grease went into getting it back into working condition but I think it will be worth the time.

-

It drove the guy nuts at Ace hardware trying to match the thread. He wasn't going to give up but he finally did. I had to order the screws from China, I could find them anywhere is the US. Yes it does fit, I'll look at rotating the rod and let you know what happens.

-

Thank you, I bought the one from cutex. I'm about 90% done with the machine. I also ordered the screws for the bed cylinder cap that were missing, tried to buy them local but it is a weird thread. When those come in I have to watch your video on timing the needle and then I am going to give it a try.

-

Sorry I didn't provide enough info. Here is a picture of the needle and presser bar setup. The second picture is of the presser feet, the one on the left is off my machine and the one on the right is what I ordered for a 153W but it was wrong. The 153W 100 is different from the 153W 101 and up. The foot I ordered in much heavier than the foot that came with the machine, but will not mount to my machine. I found CUTEX SEWING Presser Foot Singer 111W151 211W Needle Feed Type Sewing Machine #229882 (picture 3) but not sure if it is the best for leather. I hope this make more sense now.

-

Well just went to install the presser foot I bought and I learned that not all Singer 153Ws are the same. My 153W 100 only has the presser foot (slot left to right not front to back) and the needle bar. I have looked online for a new presser foot but the only thing I find is the 229882 presser foot. Is this all that is out there? Is this fine for leather? Any suggestion or advice would be greatly appreciated.

-

Uwe, I repair clocks for a living and leather work is something I have picked up for therapy. I know enough about clocks that I can repair just about anything that is put in front of me, but when it comes to sewing machines I am flying by the seat of my pants. I've always felt if you have not worked on something and there is a manual available then you buy the manual. Thanks for the pdf files.

-

Uwe, that is what I thought. With a holes facing straight up it is easy for stuff to fall in and other holes are in areas where depree from fabric or leather can fall in.

-

I've been trying to make sure all holes oils are oiled and the machine moves freely before I ever run it under power. I took a thick felt wheel and used a hole punch to make a round wick that after rolling between my fingers fit the hole perfect.

-

Yetibelle, Thank you for the reply. I agree taking photos is a good idea, but sometimes you don't see the screw that is holding a part and you might force something you shouldn't.

-

I have search and search and can not find anyone selling a repair manual for a singer 153W. I do not want a parts manual or a general setup and service manual. I am looking for a repair manual that will describe had to remove parts and the order they go back. Any help would be greatly appreciated.

-

Thank you for the help. Several of the oil holes will filled with dust, dirt and debris. I cleaned them out and when I removed the old felt it was really hard and I could not see how it worked as a wick. The large hole with the cup near the head was packed with a cotton string that I am going to reuse. It looks like it was just wadded up and the cup screwed down on top. Trying to make sure the machine is cleaned and ready to run before I use it for the first time.

-

I am restoring my Singer 153W / 100 and I have found a couple of holes what appears to be hardened wicks. Can anybody tell me what holes should have wicks and where to buy them?

-

Is there a foot that you would suggest for general leather work (belt, bags, hats)?

-

Uwe, Thank you very much for your video. The screw on mine is flush mount so I didn't see it. After I loosened the screw it came right out.

-

Still working on cleaning up the machine and I ran into another problem. I removed the thread tensioner assembly, but the post that goes into the machine will not come out. I am able to turn it wil a screwdriver so I know it is not frozen in place. Is there a lock somewhere that I am missing?

-

Thank you Uwe, that really helped me to understand what it is I am adjusting and how it works. The knob on your machine moves a lot easier than the one on mine. I will take my Dremel and try and clean up the threads.

-

Thanks, after I get it all cleaned up I'll give it a try.

-

Bob, Thank you very much for the quick responce. I printed out your instructions and went and took a look. I have attached the photos of the screws I believe you are referring to. The only discrepancy I found in your instructions is the screws were on the left looking in from the top. How much would you suggest turning the screw to change from a 5 to a 6 TPI? I thought about changing the shaft, but if you say it's a big job I think I'll pass. I've tried to find a service manual, but no luck. I did find the Consew 223-227 are a knockoff and their operating instruction are easier to read. Thanks again, Jeff

-

Hello, I have been reading the forum for a while now trying to learn about what I need to sew leather as a hobbyist. I has decided to hold off buying a machine and as things go a good deal came around on this singer 153W. It has the 3 phase motor that has to go, but the machine turned very smooth so I decided to give it a try. I have been working on cleaning it up and have found a couple a problems. My biggest problem is the thread length adjuster. I see that there are places in the threads of the shaft that have broken off and it makes getting to the 5-7 thread length hard/sketchy. I have come up with two ideas to make it work since I can't seem to find a new shaft. One is to drill a hole in the knob and install a second pin that would track in a non-broken section or have someone make me a new knob with a complete inside thread that would not put all the strain on a small section of the gear tooth. Any help or advice on repairing and using this machine would be greatly appreciated. I fix clocks for a living so I do have mechanical experience, just not on sewing machines.