buko

-

Posts

23 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by buko

-

-

It appears that adjustment worked. At first when I tried it the thread was still fraying so I took the plate off and noticed that the hook was splitting the thread. I replaced the needle and it started sewing fine. I guess I must have bent it at some point.

The thread I have seems to fray very easily though. Its bonded nylon from Superior Threads but I'm not sure if I'm really a fan of it.

-

12 hours ago, Wizcrafts said:

This could possibly be caused by an improperly adjusted check spring. Try lengthening the stroke of the spring. This will keep the top thread taut until the needle has fully passed through the leather and comes out the bottom layer. Too short of a stroke may allow the thread to be too loose as the needle makes contact. This is where the thread splitting begins.

Ok, this sounds like what is happening. I see the thread go really slack as the needle makes contact. When you say "lengthen the stroke" do you mean adjust the tension or do you mean rotate the check spring counter clockwise? Or both?

-

Let me first start by saying that I know very little about sewing machines. This is the first one I've ever used. I've been researching for months and finally bought a used Consew 206rb-2 from a local sewing machine mechanic that restored it. To use it for leather, I replaced the motor with servo, put a 50mm pulley on the motor and replaced the wheel on the machine with a 145mm pulley which has slowed the machine enough that I can control it.

Now the problem: any time I try to use a 135x16 size 22 needle the top thread comes unwound and breaks. I've tried both #138 thread and #92 thread with the same results. When I use a 135x17 regular needle it sews fine. I've checked the hook timing (after watching videos) and it appears to be ok. I've adjusted the tension and it doesn't seem to affect anything. I've attached a photo to show what I'm getting. The stitches on the brown leather are with the normal needle and the ones on the black leather are with the leather needle. The blue thread is #92 and the black is #138. What am I doing wrong?

-

Before the finish but I caution you that if you aren't going to use a natural finish like beeswax or carnuba wax you may not get good results. You are oiling the leather after all and most finishes won't adhere to oily leather. I would test the resolene on some scrap after the oil has "dried" for a couple of days. Kiwi neutral polish may be an option for you rather than resolene since it is designed to go over the top of waxy finishes.

I don't use resolene so I can't really help you with that one honestly.

-

You can use neatsfoot oil anytime after tooling but if you are going to dye the piece use the oil after dying. The oil usually causes more of the dye to come off so be aware of that. I use a 50% beeswax 25% neatsfoot oil 25% beef tallow homemade balm to finish my pieces. I warm the leather before applying to help it soak in. It softens the leather and gives some water resistance to the piece.

Best thing to do is test on some scraps and see what you like the best.

-

On 10/9/2017 at 1:37 PM, the gafer said:

Fantastic work I am thinking of doing a bag myself but as I have only really made dog collars I am really stuck on ideas tbh

Gafer, what kind of bag do you want to make? I highly recommend you buy the build along patterns from either Ian Atkinson or Nigel Armitage both of which have good instructions and are only £10. Also, the book "The Leatherworking Handbook" has great ideas and techniques and is worth its weight in gold.

-

17 minutes ago, bai said:

I'm playing around with a kangaroo hide I purchased and need to make a few extremely slick pieces of leather that I will withstand flexing. I'm playing around with a few waxes/polishes I purchased but I'm thinking the experts can get me further ahead with some well timed advise.

Basically slick as possible and it will be folded in half thousands of times.

Edit: tried so far Lincoln stain wax shoe polish and Job site Heavy Duty Waterproof - and maybe I'm just rushing it and need to give it a few days but its got a slightly tacky slightly waxy feel.

Searching here I'm going to grab some Sno-Seal to try but anything else?

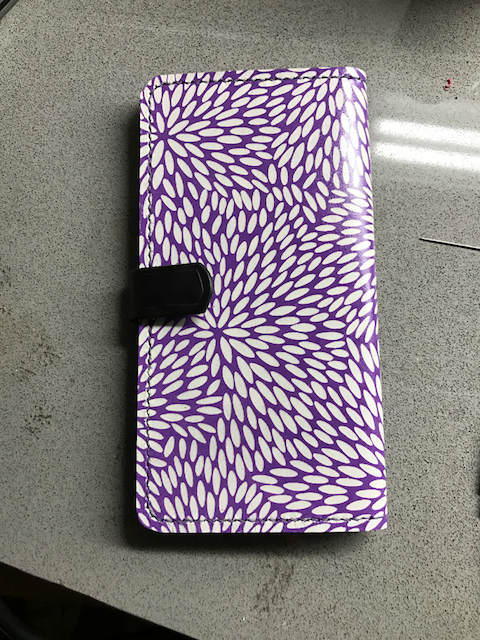

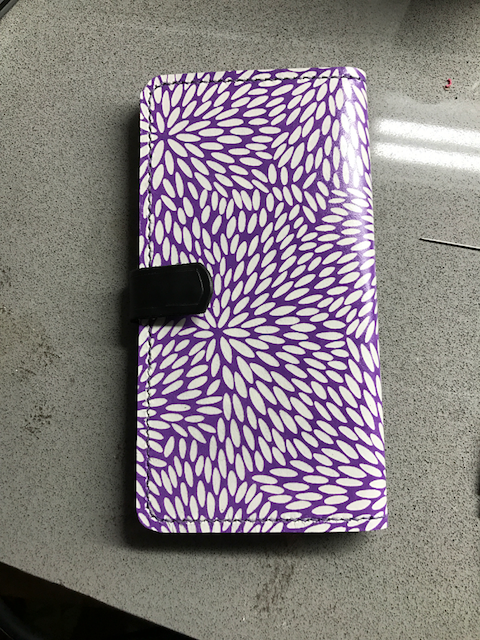

If by "slick" you mean glossy, you could try Kiwi Neutral polish. If you mean slick as in plastic coated you can try Mod Podge. I use it on some washi covered wallets and bags that I make and it will fold without cracking. Not sure what you mean by thousands of times though. Here is a picture of a leather wallet, coated with paper and Mod Podge

-

5 hours ago, Ken Nelson said:

Update: I got a "bad' check for this splitter and still have it for sale. I got the extra blade back for it, so it has a brand new extra blade for it. I will take the $450 with the new blade but you will be responsible for shipping if I include the extra blade. US Postal Money order or I hold you check for a week. I need to figure out how to take paypal as I spend a lot of money through them. LOL

Ken, if you want to take paypal all you have to do is send the buyer the email address you use to login to your paypal account. They use that email address as the recipient. You can also get their email address and send them a bill from paypal which is a little easier. Hope that helps!

-

On 4/25/2017 at 11:26 AM, Gregg From Keystone Sewing said:

I think Pfaff may sell various springs for this? I'm not sure at all, just speculating. I was looking in the books for 1245 and 335s with this type of two spring pressure foot setup, with nothing for sure. I've seen different subclasses with different spring part numbers, maybe that's it?

First off, I know very little about sewing machines so take what I say with a grain of salt. But my first thought when I saw Uwe's post was maybe you could buy a spare spring and shorten it to reduce the pressure.

-

13 minutes ago, Wizcrafts said:

I buy Organ 135x16 leather point needles for my walking foot and Singer patcher machines. I have them in sizes up to #24.

Thanks Wiz. I have plenty of needles in all sizes but I was specifically looking for the "LR" or "LL" needles that add a slant to the stitch as shown in this picture from the Groz Beckert brocure:

-

Perfect! I'll call and order tomorrow.

-

6 minutes ago, Pintodeluxe said:

You might try Schmetz needles. They have 135x16 needles in size 22 in a myriad of tip styles.

They might have the type you're after. I had to special order mine.

Thank you. May I ask where you special ordered from?

-

I just bought a Consew 206rb and I'm in the process of getting it ready for leatherwork. Studying all the great posts on this site it looks like I will mostly use size 138 thread for much of what I want to do. Looking at the Groz Beckert guide, it looks like I want the LR points to approximate the look of a saddle stitch but I can't seem to find the size 22 (for the 138 thread) in stock anywhere online. Searching this forum it appears to be a common problem.

That said, can anyone recommend a different manufacturer that makes a similar slanted point in that size?

Thanks!

-

Bridle or Latigo would work well for that. Ask your supplier to split it to the thickness you want.

-

1 minute ago, KingsCountyLeather said:

Interesting.... but sounds like a lot of work.

I ended up making a simple belt after and he was happy..

thanks.

It is. I regularly stamp bridle with my maker's mark using this procedure but I'll never do any significant tooling again. Took too long and I made too many mistakes. Its a good method for really deep monograms though.

-

line the inside with dyed pig or calf skin (or even sheep) and then stitch them together. Someone asked me to make a purse that was pink on the outside and black on the inside and I wasted a good bit of leather learning this lesson.

-

You can tool un-cased bridle by heating the tool prior to tooling. Make sure you have a leather glove on for the hand you are holding the tool in and heat the tool with a heat gun. Takes practice and patience but it works.

-

You can download a program called Inkscape for free that is an opensource vector drawing program with similar features as Adobe Illustrator (the gold standard for making templates)

I use a program called Affinity Designer which is almost as good as Illustrator but a fraction of the price.

If you use one of these programs it makes it simple to send the templates out for laser cutting if that's something you want to do.

-

Yes. It was my first concern and I did a lot of research and experimenting to get it right. I tried 20 different adhesives until I found one that worked and wouldn't wrinkle. I ended up coating the paper with good old Mod Podge and then proceeded to scratch the dickens out of it with car keys, stitching irons and anything else sharp I had lying around. It was hard to scratch and, being veg tan, if I had done any of those things to it without the paper it would have been all marked up anyway. The edges are where the problems will be most likely. I'm still trying to figure that part out. I'm making some handbags and I'll be turning leather over the edges to protect them.

That said, it probably won't be life-time durable but it should last a good long while before it needs to be replaced.

Edit: Oh, and these are ladies' wallets so not for putting in your back pocket. That would never work IMO.

-

Hi everyone! I'm fairly new to leather-working and this is my first post. I thought I would post a picture of some wallets that I made for Mother's Day gifts earlier this year. I think they are kind of unique. 1mm veg tan with Japanese washi paper laminated to the flesh side. Critique always welcome!

.png.d07f5d7656144c4ec27f3ef77682e1ab.png)

Club Stamp

in Stamping

Posted

Jimmy, I made you a version of the logo you can send out for a stamp to be made. Its not perfect - just did it real quick but you can have them adjust it for you. PM me your email and I'll send you all the files if you can't download these here.

md club logo.pdf

md club logo.svg