-

Posts

29 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Cambridge, Ontario, Canada

-

Interests

sewing machines, computers, Ham radio and repairing old gear!

Machines: Singer 29K71, 29k173, Juki LU-563 , Singer 107W1, Singer 107W102, Juki DDL 555, Merrow A-3DW, Juki MO-816, Singer 47W, Singer 144W, Adler 67, Mitsubishi dy-340 and too many more

LW Info

-

Leatherwork Specialty

Bags and repairs including shoes

-

Interested in learning about

I like Singer machines

-

How did you find leatherworker.net?

Looking at diagnosing an old Singer 29k71 that will not sew.

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

paqman's Achievements

Member (2/4)

-

Lol ok?!? sure. Thanks.

-

Nope, i just too many machines. I would love to keep them all but i already have multiple walking foot machines including the 29k71 and the 29k173 as well as my Juki LU563. If you know anyone whos looking for an Adler 67 let me know... I also have the 144W that i have for sale and i have a Mitsubishi DY340 that i am re-building for my dad. Additionally, i just picked up a Bonis Model A Furrier machine. Andre

-

-

-

I do now! totally makes sense with a larger hook i would need slightly more takeup... No matter... i have ordered the correct hook. thinking about it, someone with a machine shop could really modify this machine to do pretty much anything. This machine can also be modified using off the shelf parts. I have been thinking about getting a foot bar off of a 111W as its the same diameter and would allow me to use more common type feet. Andre

-

Ok more developments: The hook i bought is the HAD-267TR which really looks similar but the basket is different. It was 15$ so worth the risk. So to be clear for anyone looking to know if you can fit a 167 hook into a 67 to upgrade it to a large bobbin, the hook will fit and im sure the basket would also if i had the right one but the opener might rub and need to be modify or be replaced by an opener for a 167. The basket on the HAD-267TR is slightly taller and wont lock into the throat plate and hits the bottom of the slide plate so that wont work. BTW, HAD-267TR is used on a Adler 268-FA which is a post bed machine. this leaves me multiple options: 1- Just order the right hook (I did... ) 2- Order a basket for a 167 hook to see if it will fit and modify the opener to clear the hook. 3- Order a whole new hook for a 167 and see if perhaps the hook is slightly smaller and will clear the OEM opener 4- Experiment and see if a basket from a Juki LU 563 will drop into the HAD-267TR hook i have and use JUKI large bobbins (and make the opener fit) This rebuild is really going to cost me... Andre

-

sooooo i got the hook today. I ended up getting a hook for a 167 (Bigger Bobbin) instead and took a chance that it would fit as it seemed to be mounted the same way. I was right, it fits perfectly... the only thing that does not fit is the Opener. Looking at pictures, they look identical but mine rubs against the hook when i turn it so i suspect the opener for the 167 is slightly wider and allows for the larger hook. Can anyone confirm what the difference between both openers? Looking at the service manual, The opener for the 067 is 067001700 and the opener for the 167 is 0167001700. I thought about bending the opener out a bit to make room for the hook but im worried it wont work and maybe even break it. Thoughts?

-

Made the plate, and it looks good... Got a piece of Stainless and was able to file a nice angle on both sides and after a lot of filing, i got it to fit nice. Also ground the underside and it was not easy but it should work. I also received my Decals. Waiting for the Hook now.

-

Thanks! yep im waiting for the hook to get here so that i can figure out how much to gouge out... im thinking a forstner bit big enough to take off some material from the underside of the plate. Not sure how i would do this for the stainless one yet...

-

Thanks Everyone for the replies. Found a bunch of useful parts and im waiting for them to come in the mail. This includes new Decals as i decided the machine is nice enough to rebuild clean and repaint as most parts are there and its not worn out besides the throat plate and feed dog. I used some Hammer tone paint instead of the regular grey as i thought it would look really nice. The right slide plate is missing and i cant seen to find a replacement so i made one out of plexi glass for now. I may go to the metal supermarket and find a nice piece of stainless to make a new one.

-

Hi all, i have once again acquires more sewing machines. A Local factory is closing and they are tearing it down and they used to make chairs and seats and had lots of machines for sale. A few months back, i bought a few Juki walking foot machines including a LU-563 and LUH-521 as well as a 47W66. I have since sold the LUH double needle machine but kept the other 2. I talked to the owner a few days back and he made me an offer i could not refuse on the last 3 machines he had for sale, an Adler 67, Mitsubishi dy-340 and a Singer 144W (20 in long arm and huge bobbins, this thing is a beast!) The Adler is missing some parts and i need replacements. I would really like to restore it and get it back in working order as its a really nice machine and is mostly complete. The hook was there and was rusty and stuck so i started cleaning it and got it free and started working on cleaning it up and realized the hook is just snapped off. I can find hooks online but they are over 200$! if that's what i have to pay, fine but still, it seems steep. I am also missing the slide plate on the right side as well as a set of feet. There are parts available, but some are harder to find like the slide plate. Hooks are pricey, feet are all over the place and seem cheaply made. I read somewhere on the forum that there is a mod to grind the foot bar to accept 111W style feet? Where do you guys get your parts for Adler machines? There is no dealers locally, there used to be one but they closed down Andre

-

ok so i struggled to adjust everything and it kept jamming, turns out, my lever kept slipping sooo.... i stopped at the metal supermarket and bought some aluminum and re-made the lever. Much better now! I got enough to remake the other bracket also but it is locked in place and is solid so i may keep it.

-

Thanks! Yep i thought about that also! i have worked with alluminum before and it can easily be worked with woodworking tools... ill look into it. There is a metal supermarket near by, ill go and pick a few chunks and see what i can come up with...

-

thanks all! I have officially rebuilt it last night, see below. The parts fit perfectly. Im not loving the plastic parts but they work, i may still find some brass stock and remake them in brass, it would also look quite nice. My main concern is the set screws stripping the plastic so i was careful when tightening them down. I had to omit the tension spring that usually stick out next to the big adjustment knob as it was also missing (Most likely broke off like the other parts). I put a washer and screw in there to keep that dial from falling of the post. Luckily, i had this black spring and installed it between the lift rod and the existing hole in the casting, this keeps the knee lift tension rod down at all times so pushing the knee lift increases the sew width and allows it to return to centre when you let go. The lever i made is used to adjust how you want to sew (Width), left to centre, side to side, right to centre. I have to drill the 2 outer holes once i figure out the limits of the needle but doubt i would use those settings. There are limit set screws at the bottom that limit the side to side movement so the needle wont swing out too far. The large knob needs to be loosened to allow the knee lift to adjust sew width on the fly, if you tighten it, it sets the width and wont allow the knee lift to move. There is a right hand screw keeping the knob from coming off when loosened all the way which is a nice touch.

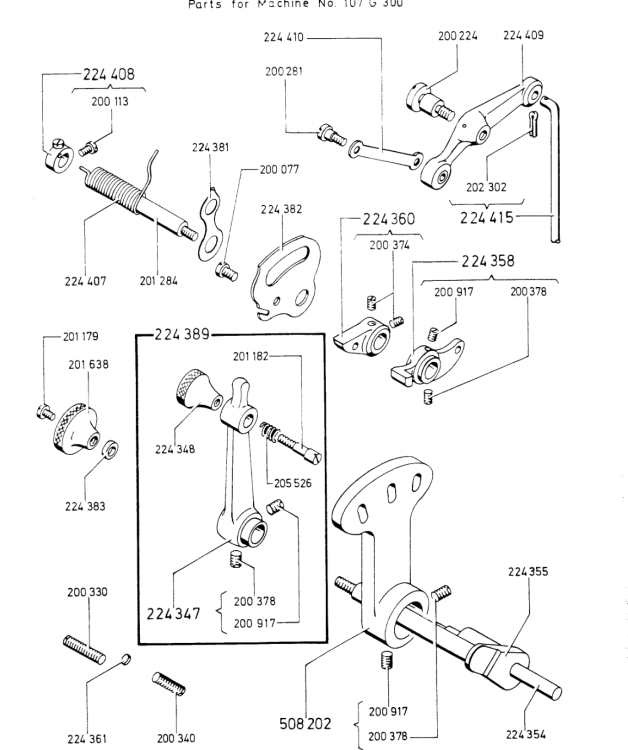

-

ok so i thought i should be able to make those parts in brass but could not find appropriate stock locally so i ended up getting some delrin and made the parts that way. Not perfect but it will get the machine functional. I also found that Singer made a 107G302 which used the same parts. Unfortunately, the lever is the same part and still unavailable and the other part is slightly different with part number 508202 but again, its not available. Lastly, i had a spare timing belt for a 107W1, part 224400, and figured it would fit, well, it wont. This machine uses a slightly longer belt, part number 224303. So i guess im using the old link belt till i figure something out.