garyo1954

Members-

Posts

12 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by garyo1954

-

Great! If you haven't already, check out the Epilog site. A ton of information there with downloadable samples you'll be interested in.

-

chrisash, good point. If/when (and you know I will) do it again, I'll likely use the initial G. Maybe circle G and bevel it. After using block fonts a thousand times it was nice to see something different for Christmas. Script is, IMO, a more personalized touch. Nonetheless a block font would or just an initial would work better for this application. Thanks!

-

Took a lot of work, reading forums, making mistakes, and making more mistakes to learn some of that. Being a member of a couple of laser pages on FB where they do nothing but diagnose laser problems and talk about how to do things helps a lot. Started a new wallet. Not sure I can bevel it like I wanted. I may try just to to see what happens. Thinking to use the black for the inside...... We shall see how it goes. (Don't expect much since this is wallet #1)

-

LatigoAmigo, Nothing wrong with a homemade laser. My first CNC was home built as well, and I learned more during the build then any amount of book teaching available. Nothing comes close to learning by doing. Great leather work as well. I love the look of it! Wish I could show work half that nice! Just amazes me to see it! As far as 75% power, that's out of my league. I'd much prefer to do multiple passes. There are plenty of laser guides online that offer predetermined setting, but those setting are compiled in a controlled environment, with set temperature, well aligned machine and well controlled variables. They don't/can't cover all possible situations. Setting for someone in Texas may bomb used by another in the UK. This is the main reason I've found for the hesitancy of sharing setting from one machine to the next. Different lenses, different mirrors, even different water temperatures can make a difference in laser performance. So anytime someone experiences poor performance/drop in performance the first thing pointed to is to clean the mirrors and lens. Smoke residue can build up occluding the beam. Look for spots, dots, streaks, discoloration and possible cracks or breaks in the mirrors and lens. Then check the alignment of the beam to ensure it is hitting the center of each mirror. And check the alignment of the gantry to ensure it is straight and level. Focal point of the lens is also important. You can buy a lens with a different focal points depending on the job. A 1.5" lens (38.1mm focal point) will have a smaller beam width allowing for greater detail but less focal range tolerance meaning less leeway as to the focus point. It has a poor cutting ability limiting the cuts to about 5mm at best. A 2" lens (50.8mm focal point) is a good overall lens allowing for good detail with a better tolerance in focal range. The tolerance range of a 2" lens will allow for engraving curved surfaces without a rotary in a limited space (33-37mm). The cutting ability approaches 1/2" depending on material to be cut. With a 50.8mm lens the focal point should be adjusted to the job. For an engrave the lens should be approximately 50.8mm above the material surface. When cutting, the focal point can be adjusted to cut at any depth or completely through the material by adjusting the height of the material to the lens. To cut through a 3mm material one should subtract the thickness of the material from the focal point. For example, with a 50.8mm focal point lens, subtract 3mm from 50.8, leaving 47.8mm. 47.8mm is then the height the surface of the material is from the lens. A word of caution: The closer (or farther) you get to and from the lens the greater the divergence of the beam becomes. In some cases multiple passes is the best option. Ambient temperature is something we can't control. Many have noted that certain chillers will bring the water only to the ambient room temperature which is not hardly ever optimum. For stable laser operation/optimum performance water temperature is said to be +/- 1 or 2 degrees between 17 - 19C for 50mm to 60mm tubes and 20-24C for 80mm to 90 mm tubes. Once above 24 centigrade you're losing tube life. If the temperature is getting high, drop a frozen half gallon bottle of water in the reservoir. Or put one in 15 minutes prior to starting the job allowing time for the cooler water to circulate and preventing a shock to the system which could crack the tube. (When adding a frozen bottle consider turning the machine off for 15 to 20 minutes.) Air assist helps in blowing smoke and bits away from the lens and work area and preventing flares-ups (which could turn into fires). Power and speed are different settings yet they work together to perform a given task. In most cases power and speed are set inversely. Cutting a hard material requires a higher power and lower speed while engraving a glass Christmas ornament requires low power and high speed. Tips for laser leather? 1. Wet leather, not soaking, cuts/engraves easier. But wet leather also curls more when as it dries which will cause straight lines to squiggle. 2. Use painters tape/masking tape or paper based tape over the area you area you plan to work. Not only will it help prevent smoke/soot for settling on the surface it allows for cleaner edges. Some people tape both sides their leather. I tend to use a strip of double sided tape on the bottom to help prevent curling. 3. Tape is also good for creating a contrast in dark leather which will not produce a good contrast. Once you've done your engrave you can then rub a wax based colored fill (or even spray it) to produce a foil effect. Once the color is dry you simply peel off the tape. Here's a couple I tried. You can see that weeding the smal bits f tape doesn't work out as I thought, but it gives you an idea what can be done. 4. Another good thing using tape. You can use very low power and high speeds to do a test run without marking the actual leather. 5. Only engrave leather once. Even if the engrave looks like it can be darker, its more likely you'll ruin the piece by burning through than deepening the color. 6. Although I haven't tried it, some prefer to cut leather flesh side up. They say by cutting it upside down they are able to retain a crisper edge on the surface. 7. For cleaning I was originally using Leather CPR which worked great on most leather. Then I ran across a couple of pieces where it faded the engrave terribly. Since then I use Fiebings 4 Way Care. I've also seen people who get great results with a soft toothbrush and plain water. I'm sure there are more. Just as there is way more about laser than can be put in one post. But this is getting too long so it's time to stop. Until later.

-

LatigoAmigo, thank you for pointing this out. Its total nonsense on my part to say one can cut through 4mm material at 250mm/sec. It's a misthought that should have never left my fingers nor my brain without some editing on my part. I engrave leather at 250mm/sec and cut with a straight knife. To laser cut through leather the speed would never exceed 20mm/sec. Most likely it would be closer to 12-15mm/sec since those are personal default values. Here's a sideview of the Karen bracelet from the last post. Its 3.47 mils and you can see some of the char line where it was lasered. My apologies for the misstatement. I'd like to say it won't happen again, but likely it will. Thank you for bringing that to my attention LatigoAmigo. (I had a much longer post but a crashed tab lost it. I will rewrite and repost about laser speed and power and factors affect laser performance in a bit)

-

RockyAussie, Very nice! I didn't quote your post due to the pictures but you do wonderful work, not only on leather but the machine as well. A point you made was the 200mm by 300mm (8" by12") bed is key. Obviously the bed can be, and many have, expanded those to whatever custom size they wish. (A laser guy in Sweden sells an expansion kit for a 400mm by 700mm bed which can be fitted into the existing chassis with some modification). So the size of the bed is no longer a deciding factor. Prior to purchasing the CO2 I gave serious thought to retrofitting a diode laser to my CNC router, which is no longer used. It didn't take long to realize that a CO2 laser would open up the ability to work with any organic material, everything a diode laser would plus glass and thicker materials. While there is nothing detrimental to the diode laser in general, there is more upside to the CO2 as this article point out: Commercial Laser Engravers Most ‘small’ commercial laser cutters and engravers use a CO2 laser, typically with a power of 20-40W (20,000- 40,000mW). A 20W CO2 laser can typically cut 3mm plywood and 8mm acrylic easily at full power and will run at ~5-10% power (1-2W) to engrave wood, cut paper etc. CO2 lasers are commonly used simply because they are the cheapest way to generate laser light at these power levels. The power output of common semi-conductor lasers (laser diodes) is much lower and the cost of laser diodes increases above a couple of watts to the point where they are no longer economic to use compared to a CO2 laser. It is however possible to use laser diodes to engrave wood, cut thin paper, balsa wood and pattern resist layers for PCB etching. Reducing the cutting/ engraving speed is often required. Of course at the time of the purchase, leather was never a thought. Prior to October 2018 when deciding to do something different for Christmas gifts I had never worked with leather. A bag of RealLeather scraps and some testing changed that. Along the way it was learned that some sellers send their leather and/or their patterns to be laser cut. (They sell the patterns which are cut in acrylic.) With a CO2 laser, different leathers require a different power and feed to produce the best finish and by no means have I mastered that, but a 40W CO2 is plenty capable of cutting 4mm leather with 10% power at a speed of 200-250mm per second. There seems to be no need to run a CO2 at full power. Nor to run speeds of 350-400mm per second as many do. Its not a race and no one gets a trophy for finishing first. So most leather is run between 9% and 11%, and in some cases such as thicker leather that will only cut about halfway through leading me to conclude one could laser cut and hand bevel a pattern of choice. That's the plan for this weekend. But hand tooling is quite intimidating at this point. Starting a basket weave on a belt, wouldn't you know January 1, and seemed to be doing pretty good, getting relaxed when the someone in the neighborhood decided to set off the most ear-shattering, nerve-jarring, very possibly a homemade nuclear device of the most hideous mankind has ever produced. And all this about the same time the mallet was coming down to strike. After that, not being able to get back to that peaceful frame of mind, and several other mis-strikes, we produce a ruined belt. So by no means do I consider myself more than a novice/trainee when it comes to leather. Capable, but far from fair to middling. As you can see, bracelets were the eventual Christmas gifts. One of the first pieces laser cut was the Karen bracelet taken for fitting. It did not, so rather than junk the piece she suggested punch a hole and it would become a keychain. (She did get another bracelet.) And she's brought this back asking for a bracelet for her daughter using this as the measurements. And as can be seen I'm still learning and experimenting with different leathers and trying different things. But as you say cutting leather with a any laser does produce charcoaling which can be a tedious side job. My solution, as yours, is to do the engraving and use a straight edge and utility, X-acto, or even a circular blade. (A clicker press is a new term) All told, it wouldn't appear to make a huge difference which laser one chooses if the focus is leather.

-

Not sure where you got your information on CO2 lasers. It does paint a pretty bleak picture compared to the reality of having one. A lot depends on how you take care of your machine as to the life of the tube. Overpowering it for extended periods, not using distilled water, high water temperatures and extreme climate changes all play a part. Some materials will play a big part in how long the tube, the lens, and mirrors, or even the machine, lasts. Some materials produce chlorine and/or corrosive gases, and even toxic gases (such as chrome tanned leather). PVC/and most plastics should never be cut. You'd be surprised how many times people will laser plastic and then wonder why they ended up with a gooey mass that is nerve wracking to clean up. Or the number of lasers lost to fire due to trying to cut and engrave a flammable material. Leather produces a dead flesh smell and can leave soot on the mirrors and lens which needs to be cleaned with alcohol. (Mirrors should be cleaned as a maintenance task in any case.) I laser wood, (cedar, poplar, basswood, oak, pine), extruded acrylic, and veg-tan (tooling leather), glass, and anodized/painted dog tags and ID cards. Timewise you spend more on layout than on actual machine time. Very rare to hear anyone complain of a machine timing out and when it does happen they are generally trying to run an intricate oversized layout at 1000DPI, in other words, pushing the limits of the machine, software, and computer. Now the last time I replaced my 40W tube was September 2017 and its still going strong. I run my laser 4 to 6 hours daily and there are days it runs 8 to 12 hours. Yes, the tube is only guaranteed for 1000 to 1300 hours of use. But most things you buy these days have a 30 to 90 day warranty which is equivalent to that 1000 to 1300 hour guarantee. Some claim the tube has a shelf life of two years due to the gases. Others claim to use the same tube for years beyond that. Two years seems to be the average in my case. A replacement tube is costs $90 to $125 for a 40W. You'll even find 100W RECI tubes for less than $800, but you don't need a 100W laser to engrave or cut leather. A 40W CO2 does the job just fine. Finally a 40W CO2 Chinese laser can be had for $400 or less. All said and done, the information you were given does not match the reality of actually owning ang using a 40W laser.

-

Sounds like a plan. I'll get to it. Been watching youtube videos of tools, wallets, belts, a strop, etc until my eyes get bleary. Dropped by the library and picked up a couple of books. This morning I spent identifying the stamps that came in a Caydo kit. Not sure how much stamping I'll do but I'll try. Not even sure that I know what each stamp is for but I know what they are, and tested them to see what the impressions look like. Decided I needed to order a swivel knife, strap cutter, circular knife and possibly a skiving tool. (Surprised the swivel knife wasn't included in the kit.) The leather I've been using is natural tooling leather 6-8 ounce from Silver Creek at Realeather.com. Bought it at Hobby Lobby. What else you got? Hour ago I stunned myself by finally (after a couple of hours) completed a three strand magic braid. LOL G

-

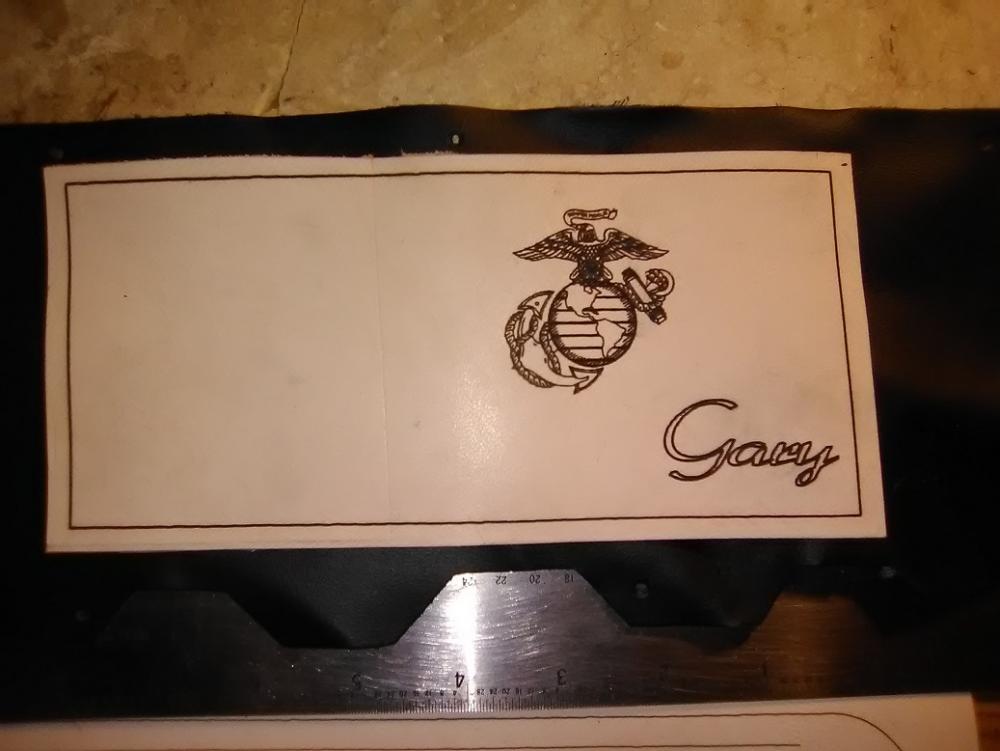

Just starting out. Backstory: In 2012 I built a CNC router. Well, it was a father and so n project until son acquired a new project named girlfriend. So dad finished it. Then in 2013 I had kidney failure. The CNC router sat for months. And when I begin to feel like doing something again, I didn't want to be around the dust so I purchased a laser. I'm on dialysis and each year I give my nurses little Christmas gifts, a token of appreciation. One year it was wooden plaques with their name, and then an engraved aluminum bar, an engraved Christmas ornament, personalized wine glasses and this year, leather bracelets. I found I enjoy working with leather, more so than wood, or glasses, or acrylic. The more I look at leather, and the work I've done I see I need to develop some skills which help me bevel and dress the edges. As well as learn the proper tools to use in other areas which will help me present a more finished product. That's me. Just your normal, everyday dialysis patient who want to learn laser and leather as a hobby.

-

40W Chinese Laser - Engrave and Cut Leather - Discuss

garyo1954 replied to Billy Hell's topic in 3D Printers and Lasers

I've owned a K40 for quite some time for wood, glass, some dog tags, not much for acrylic, but lately started using it for leather. Certainly each unit has its own nuances and certain ares that need to be addressed to become a somewhat capable laser engraver/cutter. Adding an air assist is probably the #1 upgrade one could do to prevent fires and/or smoke buildup on the mirrors. I lok forward to reading more experiences about laser and leather since that will be my focus in 2019! -

Agreed. Chrome tanned leather uses Sulfur Dichromate which produces toxic gases when heated.