LottyAfrica

-

Content Count

14 -

Joined

-

Last visited

Posts posted by LottyAfrica

-

-

Hi everyone!

Thanks for the feedback.

I've measured the burnisher, it's diameter is just over 4cm (1.57 inch)

Of course I'll be testing and trying what works for me, but as different bench drills have different minimum-speeds, I was afraid that I would buy something wrong (too fast) and therefor would never get the desired result

Does anyone have a similar burnisher - some tips to share?

-

-

Hi all,

I am looking at buying a bench drill press, to mount a wooden burnisher in.

There's different types with different speeds.

Please could you share with me what the best speed for burnishing is, approximately?

The bench drill I'm looking at, has a slowest speed of 580 RPM. I would like to know if that is OK, or too fast?

Thanks

-

1 hour ago, nstarleather said:My main gig is selling leather products...I just posted them here and did sales via Paypal.

Here's one of the posts:

Antique brass is exactly what I need. Are they solid brass? I'll send you an email

-

4 hours ago, nstarleather said:I've ordered from Alibaba, not sure if it's the same quality...actually selling them at $2 each in antique brass, gun metal, nickle and shinny brass (different manufacturer). Minimum 10pcs.

Hey Mike! Thanks for replying :-)

Could you send me a link?

2 hours ago, niakulah said:Those look nice indeed!

-

1 hour ago, niakulah said:Try Wuta.

WUTA High Quality Brass Stainless Steel Spring Money Clip Bar Slim Leather Wallet Craft Supplie Open Coil Cash Holder Clamp 2pcs

https://s.click.aliexpress.com/e/GZosI7eHi! Thanks for this, have you ordered from them? How was the quality? I'm always so afraid of Aliexpress haha!

-

16 hours ago, Tugadude said:If you need 1,000 pieces, Alibaba has them. They sell them cheap, but you would still be into it for several hundred dollars. I've seen different makes at Tandy and Springfield Leather, but not solid brass that I know of. You might try Buckle Guy.

https://www.alibaba.com/product-detail/Money-Clipper-Parts-Solid-Brass-Spring_60577514588.html

Hi!

Thanks so much for this

Flip - 1000 is a lot, I'm such a small brand.

I've tried Buckle Guy - no luck, they don't have it either. -

-

On 22/01/2019 at 1:42 PM, Handstitched said:G'Day LottyAfrica ,

This is just a very small cross section of the molds that I use, some with pencil marks, measurements etc.. Some are 'one off's ' ( but never go to waste), but the majority I use all the time. I also have some much larger molds as well.

The ones on the far left, are made of pine, mostly from off cuts and scraps. The remainder are made from MDF. Both woods are easy to shape and cheap. I do sometimes slide the molds out during drying , hence the shiny packing tape. I also use a scrap layer of leather to help with sizing etc.

You can also see how phone cases have changed in size over the years.

The one next to the axe/ multi-tool mold , bottom right, is how they use to be, ( like the one I have now ) compared to the " paving slab" on the top right.

Sure wish phone companies make their minds up Ha ha !!

So I guess you have to be a bit of a wood worker as well, ( something I'm not) . It comes with practice I'm sure

HS

This is so fun to see! Thanks very much for sharing :-) What about the board you use it on? I've looked at plywood the other day but here in South Africa it's super expensive.

Doesn't pine warp and stuff once it gets wet?

-

Hi Everyone!

I just wanted to thank everyone so much for their input :-) Such a great community over here!

I saw it mentioned already, but I found the videos of Makers Leather Supply super helpful in regards to figuring out to how this all works.

I'm considering ordering a template and then clown around with it!

-

1 hour ago, Mattsbagger said:Hi!

Thanks, but as you can read in my post - I've have looked at this piece properly and can tell you, that this is not the case. I know how T-pockets work, but this isn't applicable here.Hence the mystery I'm sitting with haha

5 minutes ago, Tugadude said:

5 minutes ago, Tugadude said:Mattsbagger, look more closely, it is not separate T pockets, but a singular piece of leather on the front. No seams on the edge. I was going to try one of these and now definitely will as it eliminates the need to worry about stitches lapping over the seams.

Sure, it is stitched at the bottom of the pocket, but in this instance, since there is no T shaped piece to stitch, the maker probably added a thin liner piece to the visible piece and then stitched it to the counterpart piece on the reverse of the wallet. I am going to mess with this over the weekend and come up with something similar. If I do, I will post pics.

Yes exactly! That's what I love about it, not having to line those things up will save so much hassle and I love the clean look of it. Also doesn't get too thick.

But the questions remains - how on earth... haha! Would love it if you'd be able to share your knowledge on the try-out!

-

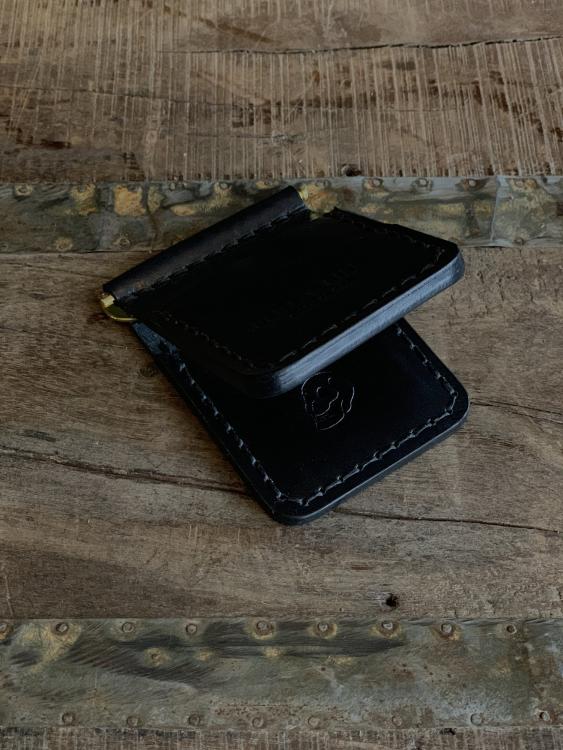

Hi friends

I have got a question and feel super stupid about it.

Truth is, is that I'm just not good with 'seeing' how something works or goes together until somebody really shows me.

So;

Looking at this photo - why does the card in the back not fall down and slide behind the card in the front...

I first thought it would be separate compartments with a stitched line at the bottom that we can't see, but I've looked closely - we are looking at 1 singular piece of leather that has two slits cut in it and gets stitched onto the back panel.

Maybe it's lined? If so - how does one do this properly?

How does this work, I want to make this so badly but even something this simple makes me struggle which is quite discouraging

Thanks!

-

Hello,

I would like to make moulded bags from veg tanned leather.

In one of my books, I've seen a method of having a wooden block mounted on a plank. Wet leather, fold over block on plank and then another plank with a hole the size of the block, slots over. Clamp it - mould it.

From another leather worker, I've heard the bit of info that this does not work, and the only way to properly mould is with steel moulds?Can someone here share their experience with moulds & veg bags, whether the mould was wood/steel/any other material?

I would like to become more educated on the subject :-)

Many thanks

Lotty

Pro Edge Drill Burnisher

in Old/Sold

Posted · Report reply

Hi there!

Was this item sold in the end?

Best wishes