Nametaken

Members-

Posts

13 -

Joined

-

Last visited

About Nametaken

- Birthday June 5

Profile Information

-

Gender

Male

-

Location

Texas

-

Interests

Craftsmanship; wood, welding, blacksmithing, cooking, growing food, bonsai, and leather

LW Info

-

Leatherwork Specialty

Tool covers and totes, bags, and things for my wife

-

Interested in learning about

Sewing, sewing machines

-

How did you find leatherworker.net?

I’ve been looking up stuff about my sewing machine and found several helpful articles

Nametaken's Achievements

Member (2/4)

-

Interesting. Ya, I was mixing up the class part of the serial number with a lack of background knowledge on my part. I appreciate the insight. I just received a proper threading wire, I’m very excited! I will be starting off with a #69 thread and eventually trying the larger #138. Good to know. I’ll keep that in mind as I order new thread. Thank you.

-

I have a thread question for you. I read somewhere that, I thought it was singer, suggested a #69 bonded thread for general use on these. I’m not planning on doing much actual boot patching, more making things like tool covers, belts, the occasional bag maybe… would there be advantages to using a slightly thinner thread(#69) instead of the thicker thread (#138) for how these machines function under ideal circumstances? Again, I appreciate your time and input.

-

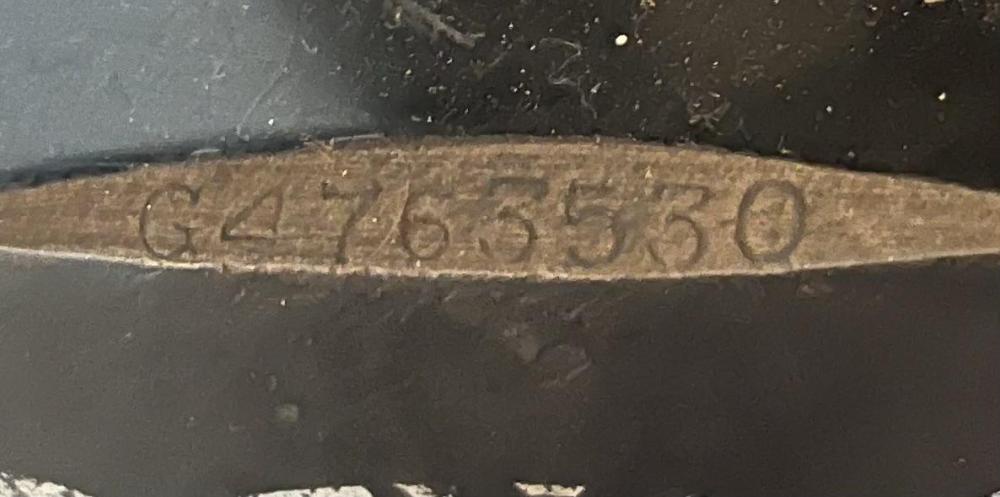

True. I had looked at a few different sites and got wires crossed in my head disconnecting the letter from the numbers. It seems this one is in the 1916-1918 range based on its number.

-

Found this out the hard way. It’s ok though, I have a threading wire on its way! I truly appreciate your insight. May I asked how you gained so much specific knowledge of these machines? It’s inspiring. I have only found basic texts from original manuals and all the info on this site, which is nothing to turn up your nose at. Again, I’m looking for resources for my own knowledge so when I am able to use it I can be best prepared and if I do need to do things like disassemble it I may have a fighting chance.

-

I greatly appreciate the tips. KGG suggested a guitar string. I have a number of options now and frequent my local hardware store. Interesting too about the thread, I will be getting some. Thank you sir. Let’s hope I can get the stuffed knocked out with one of these wires. If not I already saw your response about the steps to disassemble the head. Greatly appreciated!

-

I appreciate you pointing me in the right direction. I think when I first got it I had gotten mixed up initially and in my mind somehow disassociated the letter from the number. A different site referenced my machines number alone with the year 1881 year and later read something saying the G meant made in Germany. When I was just looking to respond to Constabulary was when I saw the site you brought up with the correct time frame. It just so happens I have a broken string on my guitar. I will be trying it while impatiently waiting on the new threading wire coming in the mail… Thank you for your input and help!

-

Alright. I found a way to make the files smaller! If they’re too small let me know, this was the “small” option. I’m looking it up again trying to find the source and am wondering it I initially had it wrong. One one site it has just the serial number dated to with in the range the 1881’s and another site is bringing in the letter saying it’s in 1916-1918. Please, let me know what you know… I’m new to all this.

-

Ok, I’m trying to resize photos and so far this is the only one I can get to upload. Let me try and find a better tutorial because cropping them is not working.

-

I wondered. Thank you sir. I have the threading tool like you showed on its way. For my general edification, because I truly want to learn about this machine, and I have read a lot of your responses in posts about these machines, would I be wrong to assume that you could explain what it is that is causing this blockage? Is there a taper to the hole? Part of my curiosity and concern is that there was quite a thick layers of what I’m assuming are years of dried oil and gunk on some of the exposed inner working parts which I would expect at this point from a machine of its age. Everything is “cleaned up” and seems to have its necessary movement except the revolving head brush that spins the walking foot which gets occasionally a slight catch when rotating it. I have found if I then reverse the direction it does not appear again. None of the movement is from sewing rather cleaning, my initial learning that lead to attempts to understand the mechanics, and attempts to thread the machine. Thank you again for the information.

-

Hello everyone, my name is Derick but I go by Muddy Camping. I’m new to sewing machines so bare with my poor vocab and knowledge of these types of machines. I’ve done all my leather work up to this point with hand stitching. I recently purchased a singer 29-4. When I got it everything moved, although I did quite a bit of cleanup and oiled it. It was missing the external spring from the back of the machine that rose the presser foot, but I have been able to side step that with a small piece of flat bar and what is a stand in for the sliding block that I intend to fabricate. My question comes in that as I try to thread the machine when I get to the step where I slide the threading wire down the needle bar in the machine head the threading wire gets stuck right near the exposed part of the paddle spring that’s inset into the needle bar just above the revolving head brush(that’s the name I’m finding in the parts manual). It’s the part that gives the rotation to the walking foot. No matter if I go from the bottom or top it get stuck in that spot. I have attached a photo to show the depth that it gets stuck at. It feels like there’s something in the shaft plugging it. What it came with is a different threading wire then is original to the machine but have found and ordered one that seems more similar to the original… I would greatly appreciate any advice that you all could shed on my situation and general information about this machine y’all would care to share. The little I know is that the serial number dates to 1881 Germany and the little bit I’ve been able to glean from reading countless posts on this forum about this type of machine and can gather from the manual that I have and what I’ve seen on YouTube. Thank you ahead of time.

-

I appreciate the advice. I’m not super clear on how to find this forum. Any advice? I’m not having luck searching it…

- 5 replies

-

- singer 29-4

- sewing machine threading problem

-

(and 2 more)

Tagged with:

-

Thank you, I appreciate the suggestion. Will do. Is there a way to move it or are you saying to repost it to that section?

- 5 replies

-

- singer 29-4

- sewing machine threading problem

-

(and 2 more)

Tagged with:

-

Hello everyone, I’m new to sewing machines so bare with my poor vocab and knowledge of these types of machines. I’ve done all my leather work up to this point with hand stitching. I recently purchased a singer 29-4. When I got it everything moved, although I did quite a bit of cleanup and oiled it. It was missing the external spring from the back of the machine that rose the presser foot, but I have been able to side step that with a small piece of flat bar and what is a stand in for the sliding block that I intend to fabricate. My question comes in that as I try to thread the machine when I get to the step where I slide the threading wire down the needle bar in the machine head the threading wire gets stuck right near the exposed part of the paddle spring that’s inset into the needle bar. No matter if I go from the bottom or top it get stuck in that spot. It feels like there’s something in the shaft plugging it. I am assuming that this is a different threading wire then is original to the machine but have found and ordered one that seems more similar to the original… I would greatly appreciate any advice that you all could shed on my situation and general information about this machine y’all would care to share. The little I know is that the serial number dates to 1881 Germany and the little bit I’ve been able to glean from reading countless posts on this forum about this type of machine and can gather from the manual that I have and what I’ve seen on YouTube. Thank you ahead of time.

- 5 replies

-

- singer 29-4

- sewing machine threading problem

-

(and 2 more)

Tagged with: