Search the Community

Showing results for tags 'problem'.

-

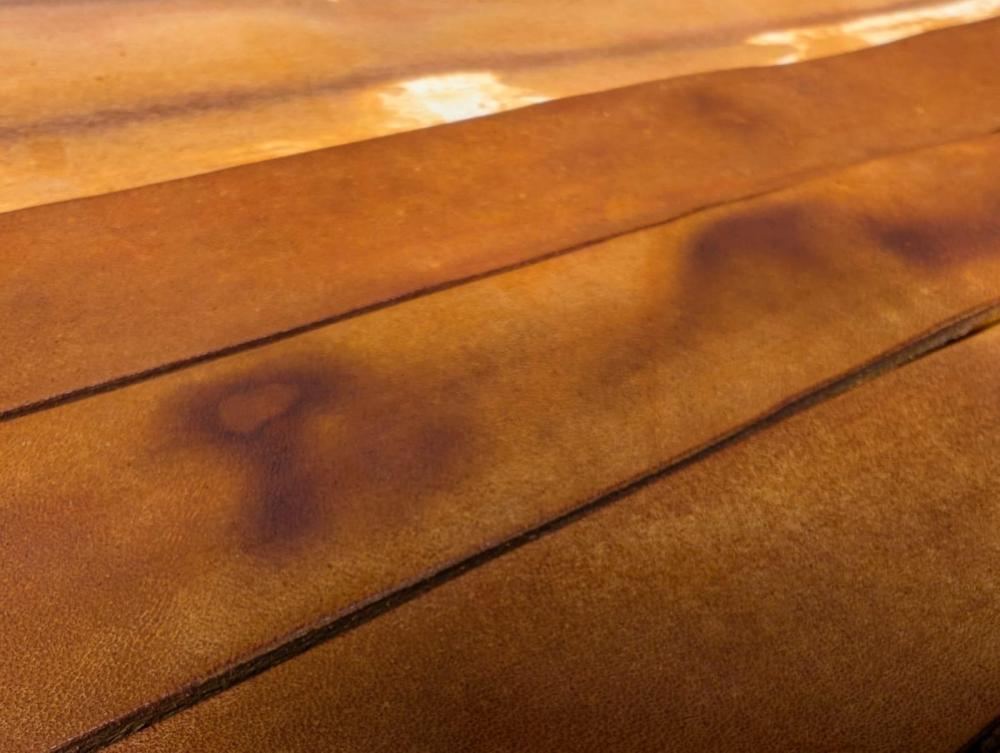

Hi all, I´m a newbie leather hobbyist. I have searched the forum but could not find my exact problem. I'm trying to deep dye some straps to make belts. I got natural veg tan shoulders from a dealer in Germany. I´m using fiebings pro dye (English bridle). The thing is that I´m getting like splashes in my leather and not an even coat. I have tried deep dyeing from 20 seconds to 20 minutes. I have tried using a dilution of oxalic acid (I think I saw it here), even fiebings Dye prep to clean the leather. Same results. I roll each strap and deep dye it on a square container. Maybe should I try a long container and dye them flat? Anyone knows if they exist? Can anyone help me? I attach some pics. The first ones are after 24h drying time. The others after applying some fiebings neatsfoot oil. Thanks

- 6 replies

-

- fiebings pro dye

- problem

-

(and 1 more)

Tagged with:

-

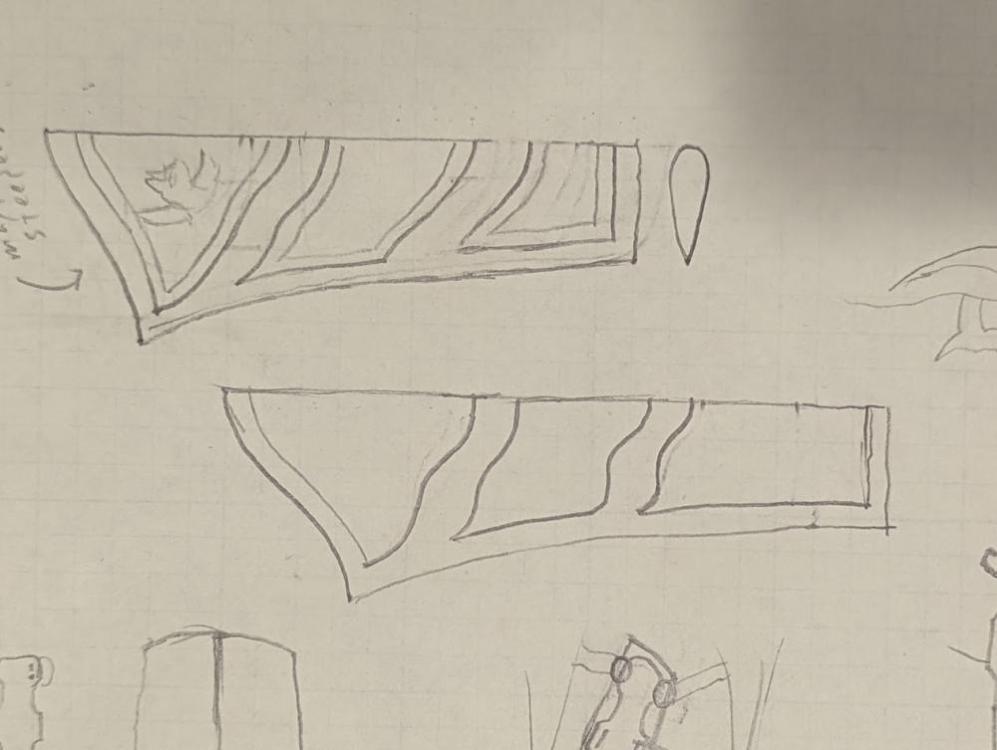

Need Problem Solving - Bending Decorative layer on Quiver

DavidK posted a topic in How Do I Do That?

Hello, As an experiment im making an archery back quiver, and anticipating a problem. The pictures hopefully will make it more clear. I plan to attach these 3 5oz decorative panels to this 8oz quiver, the quiver will then fold in half and be stitched on the long side into a quiver shape. The anticipated problem will be that after stitching the panels on while the quiver is flat, the panels wont allow the quiver to then fold into the taco and stitch into final shape. Any suggestions here on how best to attach the panels, or if a product like shoe stretch leather could help (after attaching, maybe leaving a section unstitched to stick a dauber into the back of the panels and work it into the flesh side? Any suggestions appreciated, big, small, or project breaking Thanks! David -

Hi all, I got a new skiving machine Sieck HA 50, and it seems that roller feed is rotating counter clockwise. My understanding- I am new to leatherworking- is that it should rotate the other way. Any suggestions or anyone had similar experience? I really have to pull the leather towards the bell knife. Merry Christmas everyone !

-

Hello everyone, I’m new to sewing machines so bare with my poor vocab and knowledge of these types of machines. I’ve done all my leather work up to this point with hand stitching. I recently purchased a singer 29-4. When I got it everything moved, although I did quite a bit of cleanup and oiled it. It was missing the external spring from the back of the machine that rose the presser foot, but I have been able to side step that with a small piece of flat bar and what is a stand in for the sliding block that I intend to fabricate. My question comes in that as I try to thread the machine when I get to the step where I slide the threading wire down the needle bar in the machine head the threading wire gets stuck right near the exposed part of the paddle spring that’s inset into the needle bar. No matter if I go from the bottom or top it get stuck in that spot. It feels like there’s something in the shaft plugging it. I am assuming that this is a different threading wire then is original to the machine but have found and ordered one that seems more similar to the original… I would greatly appreciate any advice that you all could shed on my situation and general information about this machine y’all would care to share. The little I know is that the serial number dates to 1881 Germany and the little bit I’ve been able to glean from reading countless posts on this forum about this type of machine and can gather from the manual that I have and what I’ve seen on YouTube. Thank you ahead of time.

- 5 replies

-

- singer 29-4

- sewing machine threading problem

-

(and 2 more)

Tagged with:

-

Picked up a new-to-me Juki 1541S and initially it sewed wonderfully. Machine was very dirty from being used in a factory environment. I'm afraid my good intentions of cleaning and oiling everything has caused some serious inconsistent tension issues. Oiled all indicated points per the manual, removed needle plate cover and evacuated all the old factory lint. Cleaned out bobbin case area with compressed air and a brush. For this project I'm sewing nylon with Tex70 bonded nylon thread. Visually, it appears that the top thread goes from having too much tension, to too little tension. This happens at all sewing speeds. Whether I'm crawling slowly or ripping through at max speed. Bottom side fares a bit better but is also not entirely inconsistent. Any thoughts or recommendations would be helpful. I've ripped my hair out all day over this! • I have checked all the thread paths and they are clean and clear, no snags. • Needle is fresh - Size 21. • Bobbin case holder is not Juki OEM - it's made by Haya (problem?) • Bobbins were cheap $0.50/ea from Amazon in a 20pk (problem?) • Hook timing appears to be correct • Check spring path is clean and clear • Tension disks are clean and clear

-

Hi everyone this is my first post ever on here and I'm hoping to get help. I've been leather crafting for a long while and I can't figure out how to prevent "spotty" dyeing like in the picture. It doesn't always happen but I can't figure out how or why it happens when it does. In this picture I used Angelus Jade color dye and airbrushed it on. All the white spots seem to be where the dye didn't absorb in. I did use acetone to deglaze it before I dyed it. Has anyone else ever had this problem? And is there a way to fix it or even prevent it from happening again?

-

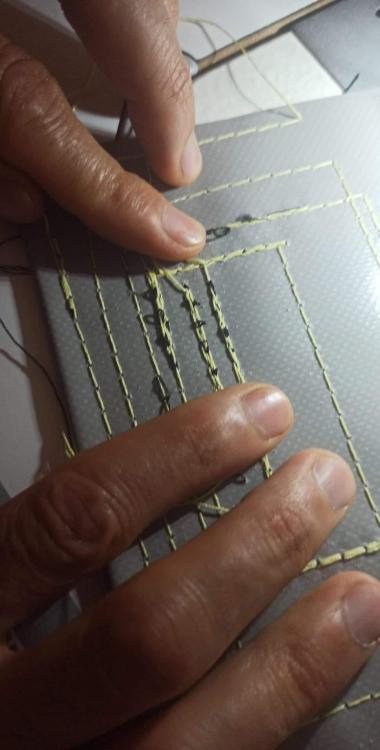

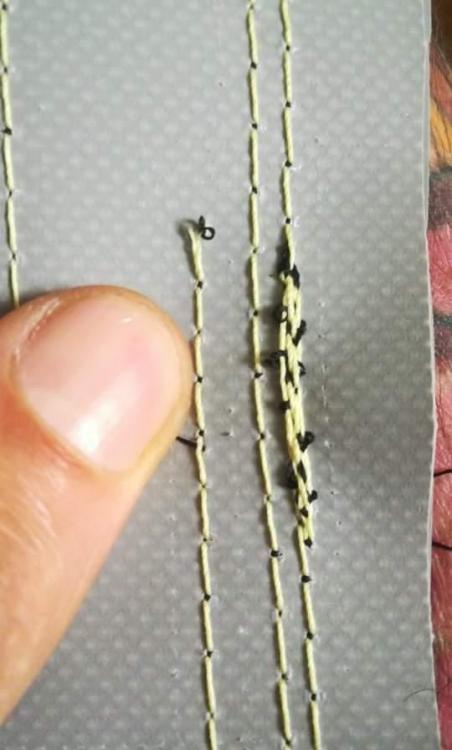

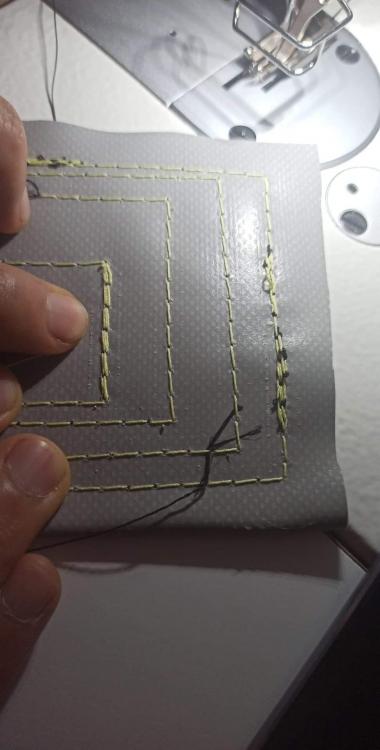

Hello, it's my first post and I didn't find a better section to post this if this is not the place excuse me. On topic I have a walking foot machine, a new one I have set it, but there's a problem occurring : Whenever I try to lockstitch the thread underneath bunches up and is happening only when I reverse Somehow the above thread is pulled under without any signs of other problems My forward/reverse stitches are perfectly matching Upper tension and bottom tension besides this are perfect and in unison I have played with the hook also to see if it's misaligned or out of time, but I don't see anything wrong with it Have tried different size of needles and thread, but without any success Tried the tighten the top tension and its improving abit, but then the botton thread is showing ontop Providing 4 pictures, last one is when I sew and then turn the fabric which makes a perfect stitch formation I will be really thankful if you have any suggestions or have experienced similar problems

- 2 replies

-

- suggestions

- problem

-

(and 1 more)

Tagged with:

-

Hello you all ! I am owner of a Pfaff 491 industrial sewing machine with the folllowing problem: when stiching, the loop thats is build by the upper thread and is normally caught by the hook sometimes isnt staying in a 90 degree angle to the hook but turns backwards so that the hook misses the loop. This results in missed stich. https://youtu.be/aKOQkTJQ338 I made a video to show the problem. In case you have any ideas I would be very happy for suggestions. greetings ! ssl2013

- 1 reply

-

- pfaff 491

- sewingmachine

-

(and 2 more)

Tagged with:

-

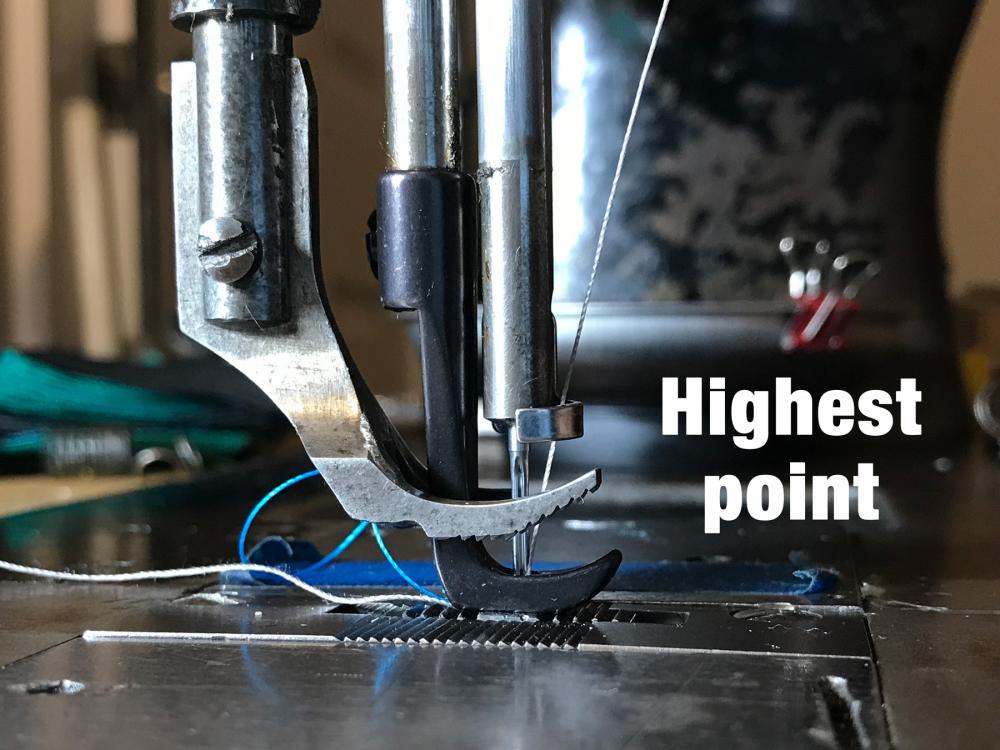

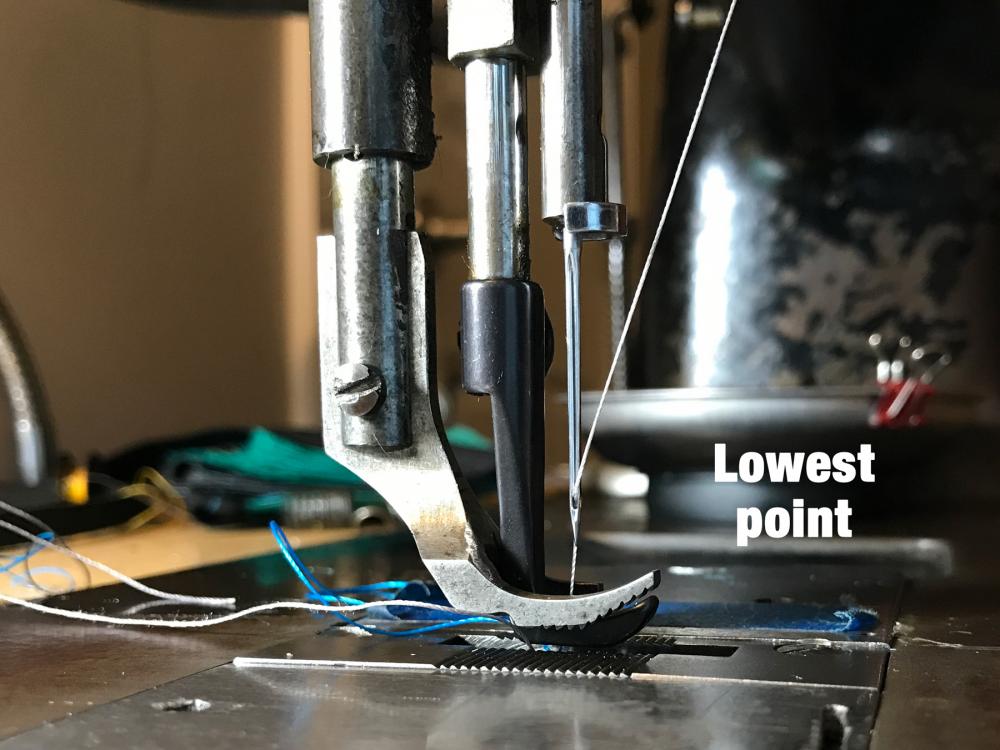

I regrettably popped out the entire bobbin ensemble. I put it back in as best as I could remember it and was able to sew away for a while. Now, the upper thread keeps getting caught in and under the bobbin. I must have put the three bobbin parts back in incorrectly. Everything else is unchanged and looks okay. What is the name for the piece I am holding in the picture? The one I wish I never took out of the machine.. Can you tell me the correct orientation of this piece, and thus the bobbin basket, while the needle is at its highest position? The needle reaches its highest position on my machine when the handcrank is at exactly 12:00. Where should the crescent on the piece in the picture be at this point? If you could provide a photograph, that would be extremely helpful!

-

Hello, I bought my Cobra Class 26 3 week ago (NEW). It´s really nice machine, and I like it a lot. But I have problems with servo motor and controlling the sewing speed. When i set speed on for example 15. I cannot sew slowly. When I press foot pedal, just a little bit it, sews immediately fast. And when i set speed on 5, it sews slow, but sometime accelerates for few stitches (like on number 10), and than slow again. But my foot pedal is still. Maybe you have some suggestions what can i do? I tried a lot, but probably not everything. Thanks a lot and have a nice day

-

Hello everybody, i have a problem. I am using fiebing pro dye chocolate and i dont know why it's getting grey color instead of chocolate. It's look like this, each photo is made on different leather.

-

I'm relatively new to the world of sewing and I've begun to get my Singer 111W113 back in working order after having it in storage for the past two years. When I bought the machine back in 2014 everything was aligned and the outer presser foot operated properly. While putting everything back together I'm realizing that the outer foot has far too much clearance, especially when sewing a few layers of material. I'm currently working with a lot of Cordura and heavy canvas for making bags. 6+ layers of Cordura are thick enough to make contact with the outer foot and provide pressure. Less material just slides around freely. I've made attempts to adjust the height of this bar but it seems to be in it's lowest possible position. Is there more to adjusting the outer foot pressure / clearance than just the screw on the top rear of the machine? Thanks in advance!

-

I regrettably popped out the entire bobbin ensemble. I put it back in as best as I could remember it and was able to sew away for a while. Now, the upper thread keeps getting caught in and under the bobbin. I must have put the three bobbin parts back in incorrectly. Everything else is unchanged and looks okay. What is the name for the piece I am holding in the picture? The one I wish I never took out of the machine.. Can you tell me the correct orientation of this piece, and thus the bobbin basket, while the needle is at its highest position? The needle reaches its highest position on my machine when the handcrank is at exactly 12:00. Where should the crescent on the piece in the picture be at this point? If you could provide a photograph, that would be extremely helpful!

-

I recently acquired a brand new Cobra Class 4 machine. I am having a problem with stitching with it. It will sew the first few stitches just fine but then it starts skipping stitches and then starts shredding the thread. It looks like the needle is piercing the thread as it stitches. I have the top tension almost all the way out and the bobbin tension is in the middle and yet it looks like the top is super tight. I don't want to mess with the timing without knowing what I'm doing. Anyone have any thoughts?

- 5 replies

-

- cobra

- trouble shooting

-

(and 3 more)

Tagged with:

-

I have a Family Sew FS-550s servo motor on my Singer 111W151. It was working fine for hours tonight, and then suddenly it started running at full speed even when the speed control was turned down and the foot lever not depressed. If the powers on, even if the foot pedal isn't depressed it starts running at full speed until I turn off the power. I'm guessing it's toasted?

-

Hi. Prior to buying my machine (Consew 226R), I did a lot of reading here so I just want to start by saying I really appreciate this forum. While everything worked just fine when I bought it, and loaded it in my truck, I'm afraid the 100+ miles of driving may have jarred something loose. Now, whenever I press the START button, the motor accelerates and reaches full RPM w/o any problems. But as soon as I release the button, it starts winding its way back down. So my first thought is it's a switch problem, but before I start fiddling with it, I wanted to see if anyone else has experienced this? Thanks! Salvisa

-

I apologize, i might not be using the correct terminology here. Tonight my Cowboy 3200 developed a problem over the course of an hour. I didn't make any adjustments or changes, so I'm not sure what happened. It started out with the bobbin just hanging inexplicably and not letting any thread feed off of it, so I cleaned out any dust and debris and lightly oiled. Now, when I sew, the thread just keeps wrapping around the bobbin.shuttle and I have to cut it off. I've been trying to figure it out for the last 2 hours. Any suggestions would be appreciated. Gary

- 6 replies

-

- cowboy 3200

- problem

-

(and 2 more)

Tagged with:

-

Hello, I bought a Pfaff 345, unfortunately I've got a small problem with the stitching legth adjustment. I can't turn the knob stronger than 2mm. Does somebody knows how to solve that problem. In the pictures you can see the longest and the smallest length adjustment, possible at the moment. Thank you. Regards, Oakley

-

Hello! I'm a new-ish leatherworker. I'm making leather wristbands as a fundraiser. I've gotten the hang of the process and am happy with my results so far. However, I'm having problems with the wristband leaving a mark on my skin in high humidity, on sweaty skin. Here is my process (I wait 12 hours between each step): 1. Tool onto 6/7 oz. leather 2. Dye with Fiebings alcohol-based dye 3. Neatsfoot oil on both sides (since the alcohol dries out my leather a lot, but I prefer the deeper dying of the alcohol-based dyes) 4. Seal with Fiebings Acrylic Resolene (for a long-lasting protection) 5. Attach snaps Since I'm doing this as a fundraiser, I can't afford to spend any more on other materials. Can anyone offer advice on how to prevent color transfer onto skin, possibly just by adjusting my process? Thanks in advance- this community is a wealth of information!

-

Hi guys, first of all a happy new year to all of you! I whish you al the best in private as for your leatherwork! But as I visited my father for these days, I just recognized the edges of a belt I made for him like half a year ago, especially the edges. Back then they were really nice and smooth. I used some edge kote, burnished it, applied some bees wax and, if I remember right i used some saddle soap to polish it again. But now the edges look quite worn out, fuzzy and I really would like to prevent that in any way... But I don't know where to improve. I know that some of you use some paraffin on the edge as fins coat, but i doubt that this would fix the problem.... I ask because i am stitching another belt right now for a friend and I'd really like to do it better this time... Any ideas, guesses or tips? I'd really (!) appreciate them! Thank you Not the best picture I know, but it is the best my mobile phone creates at the time ... Hope it helps to understand/see the problem.

-

Hello all, I am having issues setting brass rivets with my rivet setter (https://www.etsy.com/listing/118895691/stud-rivet-setter-tool-machine-hand). The posts always end up indenting the caps, even when I cut the post down. If I cut the posts any shorter than I do the caps come off without much effort. I don't think it is an issue with the rivet setter, it seems to function as it is intended. The die used on the machine is a 12mm double cap die. I am using 7mm and 9.2mm double cap rivets with differing post sizes for various leather thicknesses. My plan was to cut down any posts that were too long, but as I mentioned, the posts still indent the caps. Have any of you had similar issues? Thanks Zayne

-

Hi all! Second post here. I recently ordered a 6-7oz tooling shoulder from Tandy Leather Factory. The quality is fine, not amazing, but fine for what I'm doing with it. However, I wanted to see how some black dye would look on it so I cut some scrap off of it and tried to dye it (Gloves, wool dauber) and I found that the dye mostly just pooled on the surface of the grain and barely absorbed in. I could get it fairly well in after MANY coats, but I'm wondering why this is happening? It DOES look quite smooth, but is that it? I tried it out with an old round I had and the scrap side by side and the round absorbed the dye straight away but the newer shoulder just had dye sitting on top... Any advice? Will I need to sand it down or something? Concerned, R.

-

I bought an old secondhand leather sewing machine (an Adler 169) and all's right except the marks that makes the pressing foot: it's a little wheel with a graven impressed (I think it's for pull the leather better) BUT this leaves marks on the leather. If I got down the pressure doesn't sew good because not drag the work. The problem: The guilty: That only happen significantly in cow leather, but is the one I want to sew. There's any trick to avoid it? Or you know if a teflon wheel exist? Or something to do after in the leather to eliminate or dissimulate? Please, any idea will help! Thanks a lot!! Greta