-

Posts

16 -

Joined

-

Last visited

Profile Information

-

Location

Sebastopol CA USA

-

Interests

Original first gen Consew 206rb

LW Info

-

Leatherwork Specialty

auto upholstery

-

Interested in learning about

improving!

-

How did you find leatherworker.net?

web search

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

olivermarks's Achievements

Member (2/4)

-

Bison leather pleats to leather sheet sewing

olivermarks replied to olivermarks's topic in How Do I Do That?

It will sew through the bison no problem. The problem I have is sewing across the pleats, I can't get a good straight line or get over the thick seams easily. You can see in the picture where I've tapered off the pleat where it joins the flat plane, I need to get a french seam across there too, bit of a head scratcher... -

I'm making a bench seat for a '30's truck using two bison hides which is thicker leather than typical auto upholstery. I've sewn the blind pleat panels - I barely got the folded over fabric, foam and leather into the throat of my consew 2026rb - and I am going to be attaching a flat front piece of leather to the above edge. My logic is to hand sew the panel of leather to the above and then go over it with the Consew as it is pretty hard going across the edge of the pleats. There is going to a buried tensioning wire in the foam where I've sewn the black webbing, The flat panel will be sewn above the black lines on the pleats. Is this the best approach or does anyone have any better ideas? Staples don't hold it well as the materials are heavy. Thanks

-

Consew 206rb stitch length not adustable question

olivermarks replied to olivermarks's topic in Leather Sewing Machines

I've been using the knurled 'M' round nut for years to change stitch length. It's one of the most basic functions on the machine. The issue is that the functionality of the stitch length mechanism isn't working properly and I'm still trying to figure out why. -

Consew 206rb stitch length not adustable question

olivermarks replied to olivermarks's topic in Leather Sewing Machines

Thanks. do you mean the adjustment inside the machine behind the stitch length lever circled below? I'd better take that apart and check it -

Consew 206rb stitch length not adustable question

olivermarks replied to olivermarks's topic in Leather Sewing Machines

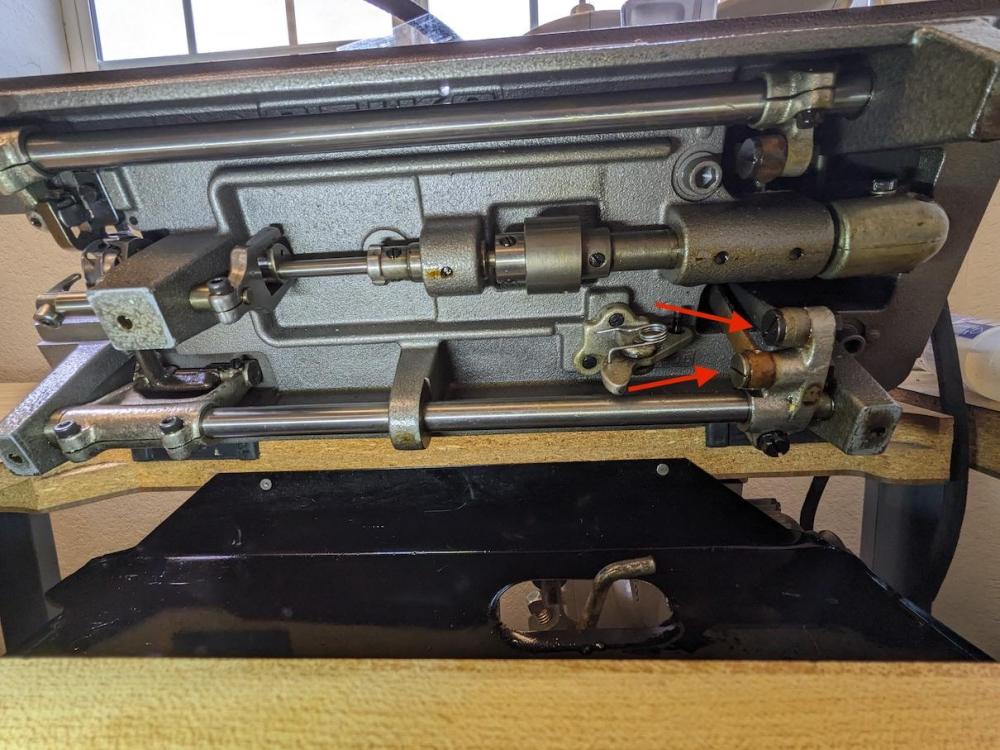

Can anyone tell me what will happen if I loosen these two fasteners marked with the two arrows? They are the base of the stitch length lever. I am still trying to get the maximum stitch size back! My machine is running like butter - I've reset just about everything to tolerances but still not getting the maximum length. I have been sewing with the stitch set at max, and occasionally the stitch length lever gives a little jump when I start sewing, which is odd. Still trying to figure out what, where, how... I don't speak Spanish, this video seems to be talking about what to adjust, not 206rb but looks useful? Thx -

Consew 206rb stitch length not adustable question

olivermarks replied to olivermarks's topic in Leather Sewing Machines

The feed dog looks a bit weird in that video because I hadn't adjusted it back after changing height etc to see if that was the issue. I'm still unclear what shifted and why so I no longer have max stitch length. At least I'm learning more about the wheel end of the machine! The forward and reverse stitch lengths are identical, i don't wan tto mess that up too. The machine is also sewing ok, no major issues. -

Consew 206rb stitch length not adustable question

olivermarks replied to olivermarks's topic in Leather Sewing Machines

I'm still grappling with the stitch length issue, spent time today trying to figure out what has changed. The machine is the original 206RB. Is the large screw head in the image below on left an adjustment point? I didn't want to loosen it until I did further research. The stitch length lever is barely moving the shaft. You can see the feed dog moving in this video as I move the stitch length lever, it is only moving in the center of the slot. I'm assuming maximum stitch length = maximum feed dog movement? -

Consew 206rb stitch length not adustable question

olivermarks replied to olivermarks's topic in Leather Sewing Machines

Thanks, i haven't watched these videos in while there's some good info on feed dog longitudinal positioning at 10:00. -

Consew 206rb stitch length not adustable question

olivermarks replied to olivermarks's topic in Leather Sewing Machines

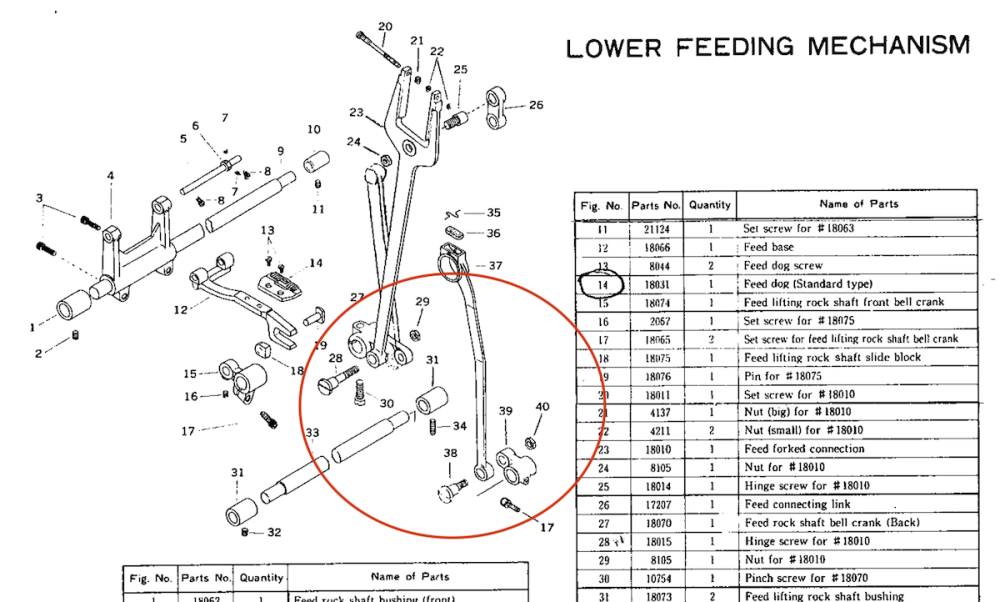

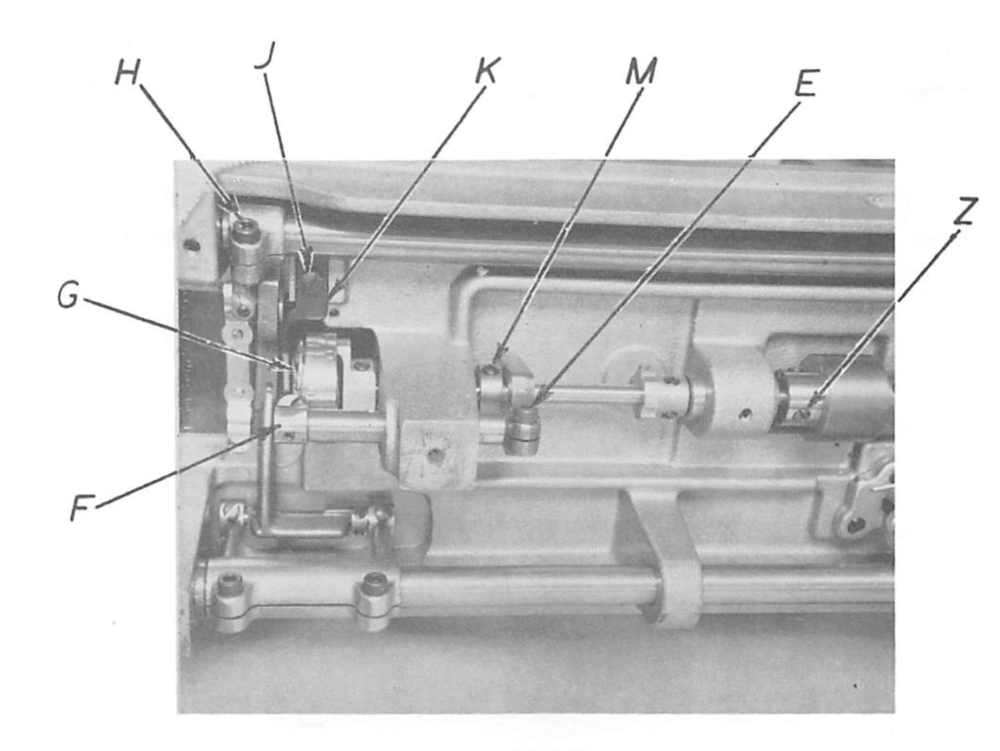

Thanks for the input. I may go down to T135 if I can find a good dark.brown color. I know I'm a little undersized on the needle for the 210 thread (It may be a 23 not a 22, Not near machine right now to check). I was testing the Bison leather I'm sewing, which is quite soft, but practicing on similar quality scrap leather. I had some leather underside tension issues and did a lot of tweaking of the bobbin as well as the topside tension when I was setting up for heavier material and thread, it is sewing pretty well at the short stitch length right now, but I'm not going to do any top stitch visible sewing on the final product until this is resolved. (It's a bench seat and door cards for a '30's truck) I checked the feed dog for slop yesterday - I usually put blue Permatex thread locker on the two screws to make sure they don't work loose - and checked the the timing etc. I think the stitch length has been compromised for a while, I just didn't realize it until I started experimenting with tension and length. The feed dog goes all the way 'back' in it's rectangular enclosure under the needle 'throat' area, but not all the way 'forward' coming back towards me facing it which makes me think something is out of kilter mechanically, but I can't figure out what to adjust, where. I did loosen and experiment with the feed dog assembly on the left of the bobbin side, and looked at the cam in the 'fork' (F & H in this pic). Also the stitch length lever, which is on maximum, was moving slightly when I started sewing which made me think something may be sticking at the wheel end of the machine. I was wondering whether to go in from the top of the machine and check the alignment described in this vid: -

I've got a strange issue with my consew 206rb where I can no longer get my stitch length longer than about 1/8th of an inch. This is after tuning up to stitch thick leather with heavier thread. I had adjusted tension at bobbin and top tension and the stitch length got really short when I overtightened. I'm getting shorter sections of stitches sometimes within a longer section of sewing. I'm using Coats star nylon 16 pt tex 210 207 with Schmetz Leather Industrial Machine Needle Size 22 - 135x16 TRI, DPx16 D Can anyone tell me what to adjust, oil or other adjustment to get the full stitch length again? The feed dog goes to the back of the plate looking down on it but doesn't travel to the maximum amount forward, I'm wondering what to adjust to get maximum travel. Thanks!

-

Auto upholstery bison hide sewing questions

olivermarks replied to olivermarks's topic in Sewing Leather

thanks -

I am in the process of upholstering an early 1930's Ford truck bench seat and door cards using two bison hides. I've done the foam and fabric underpinnings and am now moving to the leather work, basically some pleats on both surfaces, similar to the attached image but all in Bison leather, which is thick but relatively supple. I'm using my Consew 206rb and am planning on using Schmetz Leather Machine Needle Size 18/110, I haven't started experimenting with thread and the leather yet. I have Coats star nylon 16 pt tex 210 207 in brown, will this needles and thread combination work? Does anyone have any other tips on sewing Bison leather? I haven't used it before - it seems pretty pliable and a bit stretchy. Thanks!

-

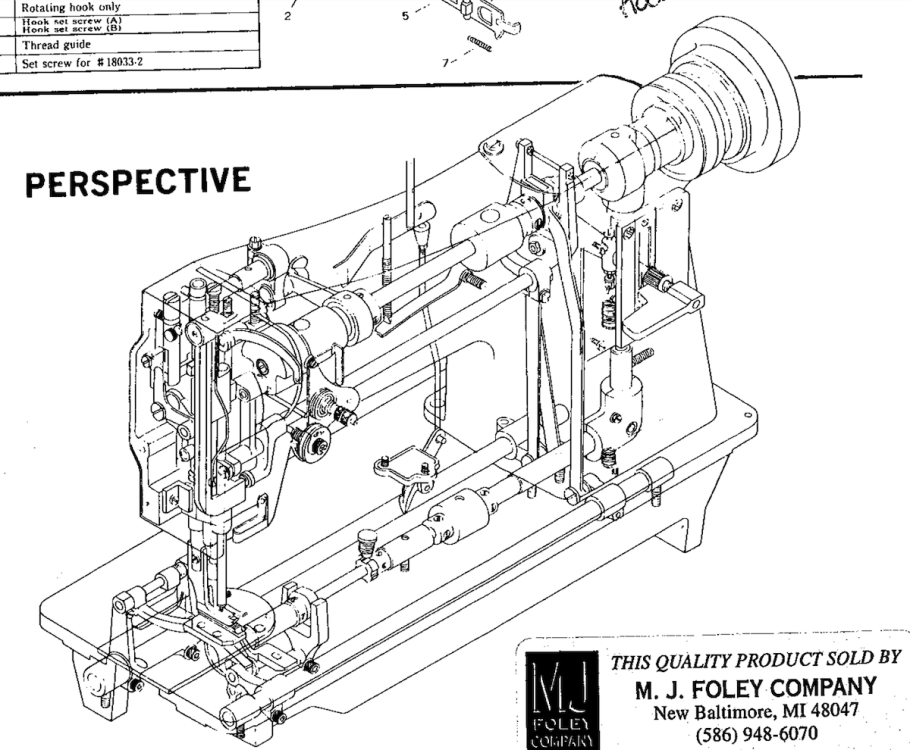

I have a consew 206rb 0, the original model. Pluses: Masses of video on youtube to help familiarize and learn, very well made machine with excellent parts availability, very mainstream machine. Should easily do wallets, purses. Minuses - Mine is a bit fussy, takes quite a bit of set up to get running right.

-

jammed consew 206rb help suggestions

olivermarks replied to olivermarks's topic in Leather Sewing Machines

Answering my own post with resolution in case anyone is searching. The thread was stuck between the bobbin case base and the hook. I had to undo the three tiny screws on the bobbin case base hook gib to release the hook and then get the thread out. Gave it a good clean up and the hook is spinning again now within the bobbin case base. If you need to remove the three tiny screws have a large clear plastic catch bag taped under the work area so if you drop one it doesn't disappear south somewhere while reinstalling. -

I have a first series 206rb I just had serviced and it was running perfectly until it suddenly jammed today - I think there might be some thread caught up somewhere behind the bobbin case. (I'm using Nylon upholstery thread). I've been practicing on the machine and often see an unexplained short extra length of thread coming out of the bobbin thread hole. Not sure if this is me being sloppy and allowing threads from my practice pieces to be pulled down the hole and snapped or why this keeps happening. I tried to pull a piece of extra thread out with pliers but was unsuccessful after the machine suddenly locked up while I was practicing piping on naugahyde/vinyl. The safety disconnect hasn't gone off - I took the foot plates off but can't see anything unusual. It looks as though the bobbin case is impeded by the tab on the hook supporting plate - I can rock the wheel back and forth enough to see this, video below. I can get the bobbin case part way out but not all the way as the two spots are about 2 inches apart, so near yet so far!Any clues on how to resolve this greatly appreciated - the machine was running perfectly and I don't want to screw it up! I also cross posted the above on this old thread yesterday as it has useful contextual info.