Josacraw

Members-

Posts

28 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Josacraw

-

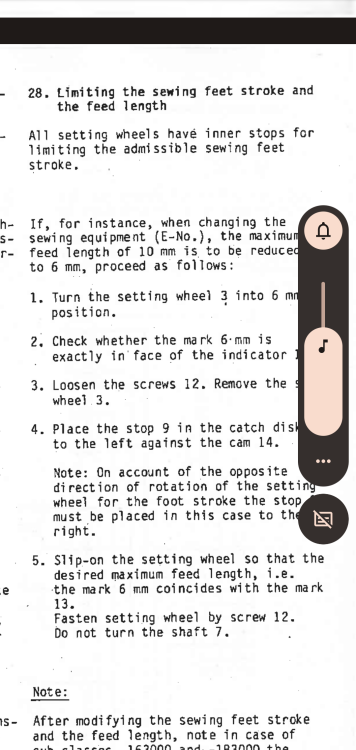

I swapped the support tape on a sail to a different size today. I won't bore you with the details but it did involve a few stitches of 45 feet. The bobbin made it through a full run with 92 thread. The machine did excellent in the thickest part of the sail plus some webbing. No dropped stitches. It also did a great job pulling the sail which is no small task. Looking at page 65 of the repair manual it appears that I might be able to adjust the max stitch length but maybe depending on the subclass it is already maxed? Have either of you guys attempted this? Sorry tried to upload the accompanying diagram but it was too big.

-

I can say without reservation it will run 92. There's talk that it will also run up to a 138 but I have not tried that. The machine came with two bobbins. More are available on eBay. So far I haven't had to buy anything for it. Looks like feet and rotary hooks/bobbin cases are also available not sure about anything deeper.

-

I also set the machine up with a servo motor. It sews 11 layers of 9oz Dacron without issue. It is interesting how there's a separate stitch length for reverse. I switched the chain foot lift to a knee lift. Bent an old piece of bike frame with a conduit bender and attached it where the pneumatic lift was on that T.I was having trouble getting enough leverage with the foot operated lift to get the thread tension to release. I need to swap the support tape on a furling jib 45 feet in length. That will be a good test of the machine. I'll report back after that. Soi far it seems like an excellent machine for what I want to do and definitely a step above the Consew 255. Also it has quit a bit more room in the throat.

-

Went and picked that machine today. Got the machine for $350 without a motor. Planning on putting a servo on it anyway. He puts a foot lift on them and pulls the three phase motor and pneumatic controller. He's running an ad in Valdese, NC on marketplace if anyone is interested. Worked several years as an independent repair tech for the local furniture upholstery industry seems to know his stuff. Heck of a nice guy.

-

Thanks for the reply Glenn! The guy has about 20 of the 291s if anyone is looking for one.

-

Thinking of upgrading from my Consew 255B to an Adler 291. I use the 255 for sewing boat sails. The lack of reverse is a real bummer and at time it has trouble with large patch assemblies. It drops stitches when I'm sewing through 9 layers of Dacron in the 1/4 inch thick range. I've got the machine well dialed in. So anyways found a affordable 291 with reverse and non of the pneumatic features. What are the limitations of this machine? Will it do a better job? What should I look at in terms of wear. Thanks

-

I thought i said in the post consew 255b. Thanks

-

Hello I know this outside of the forums leather scope but since it involves thick fabric and an industrial machine I was hoping you guys might have some advice. I'm sewing through 7 to 8 of 9 oz dacron sail cloth with 92 thread and 22 gauge needles of the SD1 variety. The machine does fine when i get under 5 layers but thicker than that my top thread keeps fraying. Should I be using a larger needle? Or should I try something else. The machine is a consew 255B Thanks

-

Well if anyone needs them I have a few bobbins and two of the rotary hook assemblies. I hate to see them molder in a box.

-

1.5 inch by .5 inch

-

Picked up a consew 255B the other day and the owner threw in a box of parts. In the box was a few of these giant bobbins. Just wondering what machine would use one so large. The photo shows a 28mm on top for scale. thanks Joseph

-

When sewing through more than six layers of 9oz dacron I'm getting top thread bird nesting on the bottom. It does not happen every time but when it does it continues for the entire stitch. It acts like the top tension is too loose and perhaps that is the case. Maybe the thickness is putting to much drag for the tension arm to draw the thread tight. I have decreased the bobbin tension and maxed out the upper tension but it still on occasion will nest. The odd thing is if it is gonna do it it does it right from the start. So far it has not started doing it halfway through a stitch. Well as always thanks for your advice. I should add I'm using a 20 gauge needle with 92 thread

-

To follow up I'm using groz 134 system 20 gauge needle in the pfaff 438 and it is working just fine. I am not running anywhere close to the rated SPM for this machine but not crawling either. When sewing through 8 layers of 9 oz dacron the thread was fraying and snapping on a 19 gauge needle but so far it's good on a 20. Visually the needle system are very similar. The zz scarf slopes gently into the eye with a slope that goes about halfway into the eye. The non zz does not slope into the eye at all. Hope this helps someone

-

Thanks Gregg! Is there any chance that a manual exists for these? I looked em up on the old googs and couldn't find a thing. The puller is very straight forward, no pun intended, and has no reverse function since it is driven off the flywheel. In sail sewing there's not a lot of need to use reverse to lock a stitch but it does come up. So it would be nice to be able to lift the puller while leaving the foot down. Not sure if anyone has seen a modification to do this. And lastly to change stitch length I believe I would adjust the center screw on the flywheel to make the pitman arm more eccentric? As always thanks. What you guys know could fill a warehouse.

-

I purchased this pfaff 438 that has an added on cloth puller. It is not the pfaff puller but some type of after market. Can anyone tell me what it is/who made it?

-

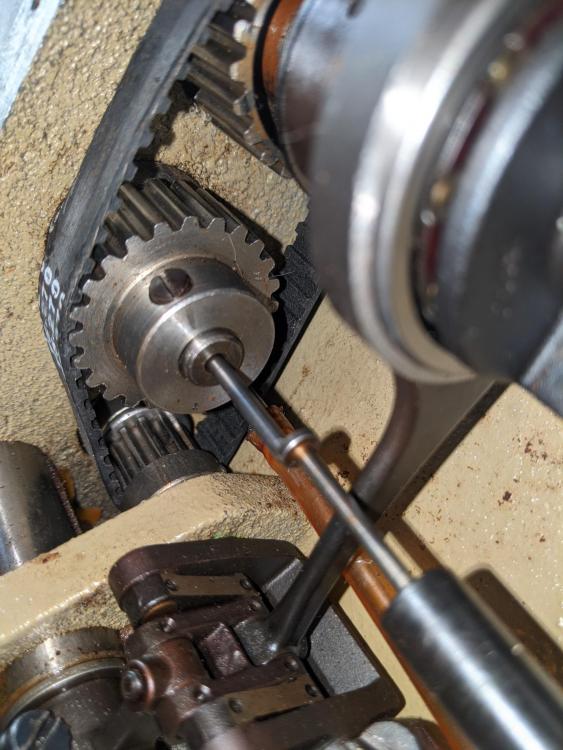

Well the machine is more or less back together and sewing pretty well. The trick that I could not see in the diagrams was the belt need to go on the other side of the oil tube. As soon as I did that it became very obvious. Of course I had to reset most of the lower end, feed , bobbin hook and bobbin opener. I'm thinking it might be worth my time to make a series of narrow metric probes to set the various distances specified in the manual. Now that it is working I'm going to switch it over to a servo motor. I live off grid and my lights dim when I turn on that clutch motor. Thanks you all for this forum it is a great resource.

-

134 and 134 ZZ needles: 33.9 mm from the top of the shank to the top of the eye, 2.0 mm shank diameter. 339.200 AC XX R We never use the full length of the needle in the specifications. 134 ZZ has a different scarf configuration so that it will work in Zig Zag machines. This is the reply I received from a groz usa rep to my question on 134 dimensions. Hopefully it helps someone else out.

-

Belt arrived from gold star(the only place I could find it). Unfortunately it is a 15mm belt which is too wide for bobbin hook pulley and I swear it is at least 2 teeth too short. I now know that it is a T5 belt at least. Update: Spoke to the good people at Premium Industrial Machine and they informed me the 438 has two different lower belts mine was apparently the older of the two. Part number 91-168275-05. I've now ordered the right one.

-

Another thought about the oil, from the way the timing belt had broken down it was clear that the oil had an adverse effect on the rubber. It was broken down into tiny chunks. Is there a macine oil that plays well with rubber? Or is this just what's going to happen with time?

-

Thank you! I found the 538 only service book but this one is much better especially in the description of the bobbin case opener timing. Belt should arrive in a week. I'll keep the forum posted. It is recommended in the service manual to replace oil pan foam. Is there something I can get locally for this? And what oil should I use?

-

I spoke to my local needle/thread supplier and they said 134ZZ is the same as 438. They also noted a 134 which has larger gauges but may or may not fit. Does anyone know the particulars of 134ZZ? I was able to find the dimensions of 134 here https://leatherworker.net/forum/topic/81816-needle-size-134/

-

I marked everything with a grease pencil and nail polish to be double safe. So far it really isn't that bad. Of course the timing is gonna be way off but that was a given with the broken belt

-

I've looked at the available repair manuals and timing belt replacement doesn't seem to be covered. Has anyone done this? Are there initial timing marks to the three gears to? It looks like it's gonna be a real pain in the ass.

-

I just purchased a pfaff 438 which uses the 438/265 needle system. I'm having trouble locating the needle gauge I would like. I want to run v92 thread in a 19-21 needle size. Are there any needle systems I could switch to? Thanks

-

The good news is global says the puller will fit the machine. The bad news is they want 400 for it. That combined with the 900 the guy wants for the 217 is well outside of my budget. There's an alternative to global called topeagle. Their LZH-217-3S-P is another 217 clone. It wouldn't surprise me if topeagle makes the Global. They quoted me 1250 for the machine and puller no table or motor last fall.