-

Posts

37 -

Joined

-

Last visited

Contact Methods

-

Website URL

https://xoab.us

Profile Information

-

Location

Portland, OR

-

Interests

Inlay and appliqué, color and design, sewing and knitting machinery.

LW Info

-

Leatherwork Specialty

I haven't done leatherwork in a very long time. I make socks.

-

Interested in learning about

Sewing machines, splitters and skivers.

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

rlevine's Achievements

Member (2/4)

-

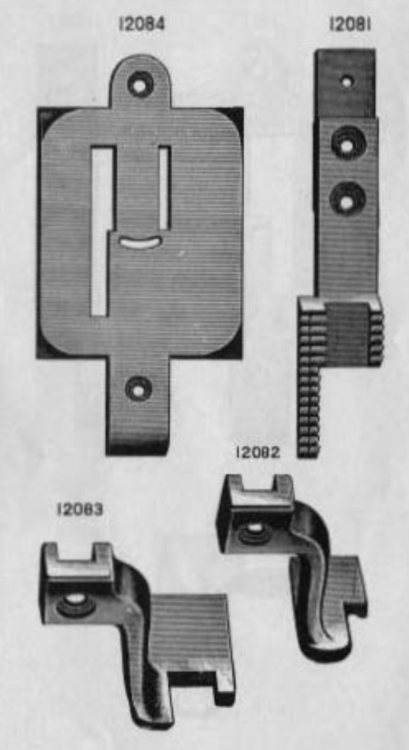

This is a _very_ long shot, but I'm always optimistic. Can anyone suggest leads on a set of up-the-arm needle plate, feed dog and presser foot for a Singer 11-16 or 11-26? I have an 11-26 that I'd like to run as an up-the-arm zigzag. (Yes, I do have some queries out to parts jobbers, but you folks often come up with great ideas I didn't think of!) Part numbers are: 12081 feed dog 12082 half-coverage presser foot 12083 full-coverage presser foot 12084 - needle plate Parts-list picture attached. Thanks! Rick

-

Singer 153W102 feed eccentric troubleshooting

rlevine replied to rlevine's topic in Leather Sewing Machines

Understood, thanks. Yes, it's a separate casting, and could be moved. I'm reluctant to do that, as it would require cutting the paint to separate the pieces. The current paint is pretty old, looking at the wear patterns, so it's been running with the mis-alignment for some time. Rick -

Thanks to you both! In this case, Bob nailed it: it has a bobbin winder on the top of the machine. It's a 211UX567B. (Not sure what the "X" indicates!) Rick ***

-

I'm curious about the rectangular upper thread guide this Singer 211U has instead of a thread pin. Can anyone tell me what it does? It doesn't appear in any of the parts lists or docs I've seen, but this is the second machine I've seen with it. This machine was running 138 poly thread in a tarp shop, so I'd assume it just provides more upper tension, but I'm curious. Thanks! Rick ***

-

Singer 153W102 feed eccentric troubleshooting

rlevine replied to rlevine's topic in Leather Sewing Machines

Thanks @kgg! Ya, there are no perfect options. I suspect it'll be impossible to find a replacement arm shaft, and the odds of the rear bushing having a matching wobble are pretty good. I didn't think to check the arm shaft and the rear bushing for issues when I had it stripped down. The issue is only perceivable when I turn the machine by hand. Running on a motor, it sews and sounds fine. Compared to the shape it was in when I started, it's a decent machine. So your last suggestion is probably the best. Run it until it has a problem, and look to swap it for a better machine. (Which was my intent to begin with!) One quick question: what did you mean by "reline the casing?" I haven't heard that before. Thanks again! Rick -

Singer 153W102 feed eccentric troubleshooting

rlevine replied to rlevine's topic in Leather Sewing Machines

I think that's it, @kgg. *sigh* Dial indicator says it's out by ~.008" See the video, below. (My pencil-handling skills didn't show it up, but a mag base + cast iron work wonders.) So what's the group wisdom on wonky shafts? A quick perusal of the usual sources doesn't come up with a replacement part, no surprise. If it was a drill press, I'd take the spindle to a local machine shop to true up, and they could get it to within a thou or so. What's acceptable for a sewing machine? Will it run for a long time, gradually making the eccentric a tad bit convex? It sews well enough. It'll eat at me, tho. What are people's opinions about selling it? My ethical bump won't let me hide it. Do I need to just gift it to a relative I don't like? Thanks, folks. Rick *** -

Heh. Two. I followed @DonInReno's advice and just searched for the unspellable "escutcheon pin" and found brass pins. I like the Singer rosette heads, but it occurred to me that they may use a rosette striker to set them, rather than having pins with rosette heads. (Thanks Don!) Rick

-

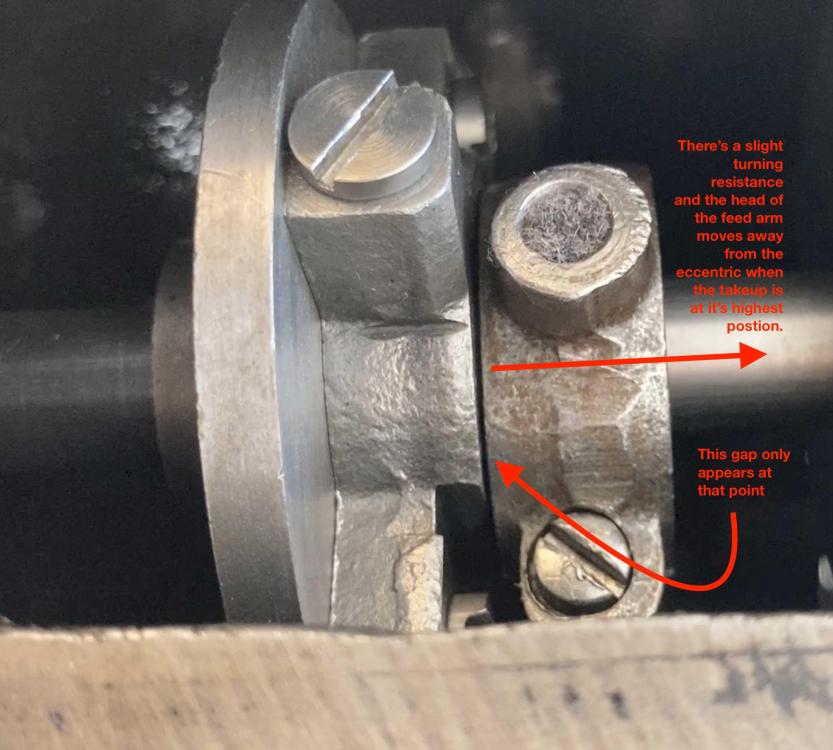

This might be an oddball question, but I'm not sure if I should worry about this, and if so, how I fix it. I've rebuilt an early 1940's vintage Singer 153W102 needle feed cylinder arm. I've been sewing on the machine, and it stitches well on the cordura I'm feeding it. But. When I turn the machine by hand, there's a slight resistance that coincides with the thread take-up lever reaching it's highest point. Also at that point, the head of the feed driving arm moves slightly away from the feed eccentric. Considering the shape the machine was in when I started, it's a small thing, but I don't like the turning resistance. (The gap between the feed arm and eccentric was much larger when I got the machine!) The resistance doesn't go away when I disconnect the belt or remove the needle rock frame, so it's something to do with the feed drive. One thought I had was to try moving the lower bushing for the feed arm slightly towards the needle, but I wouldn't think the position of that bushing would cause this kind of intermittent issue. One other observation that might be relevant is that the arm casting is very slightly rotated counterclockwise with respect to the base. It's obviously been that way for a long time, as it was repainted at some point after the arm was misaligned. Some pictures attached and a video linked. In the video, I pause when the thread take-up is at the top, and rock back and forth through that point. (And the audio in the video is awful! With the camera so close to machine, it sounds like a starter motor. It's actually pretty quiet. Thanks in advance for any suggestions. Rick

-

153W102 questions: needle choice, feed reg spindle length

rlevine replied to rlevine's topic in Leather Sewing Machines

@CowboyBob, thanks for the info, and pointer to the manual. (And apologies it's taken me so long to reply; work on the machine got preempted by life. *sigh*) Thanks for pointing me back to the manual. I was working on getting the feed dog eccentric in sync, and didn't realize I had undone the spindle position. Rick -

It's a trivial thing, and doesn't at all make a machine work better, but I'd appreciate any pointers for sourcing rosette-headed pins for replacing a Singer badge. My plan A is just filing down some copper rivets, but I'd love to find real ones. (Yeah, I'm easily amused.) Thanks! Rick

-

Help on Singer 153 stripped hook saddle screw hole?

rlevine replied to rlevine's topic in Leather Sewing Machines

Thanks @DonInReno! Great suggestions, and good feedback on helicoils. You opened up a new rabbit hole for me; adjustable dies. I've never used one, didn't know they existed. Split rounds, two-piece rectangular ones like Little Giant. Fun! Amen to the nastiness of cutting oil. When I moved into my current shop, the prior owner left some in a jar. The jar was out of sight under a bench, tipped over, and had a verrry slooow leak, a drop or two a day into some cardboard. Took me months to figure out where the stench was coming from! Rick -

Help on Singer 153 stripped hook saddle screw hole?

rlevine replied to rlevine's topic in Leather Sewing Machines

Thanks for the pointers; that's useful info. Now I just need a project that will justify the tool set cost! Rick -

I've just finished disassembling/reassembling a Singer 153W102 for bag work, and have some some random questions. First, many thanks to folks here for the snippets of information they've contributed over the years. The forum has been an invaluable source for me, as a newbie, as I've puzzled out how machines should work and how mine do or don't. For the 153W, @Uwe's insights and videos on the 153W102 feed length bits and on Singer safety clutches generally, and Eric/@gottaknow's video on safety clutches and his precise description of setting timing when there's lash in the hook gears all helped me tackle this rehab. (I haven't seen recent postings from Eric; I do hope he's still around and kicking!) Three questions: Is there any rationale for setting up the machine with 135x17 vs 135x7 needles? This one came with a 135x17, and when I set it up I put it back to the Singer-suggested 135x7, as the nice needle bar engravings were there for the shorter needles. I use both on other machines in the shop, so there's no scarcity argument to be made. The only possible reason I see is that I have one presser foot that has a higher hinge hump, and it'll collide with the needle bar when the foot is lifted and needle bar height is set up for the 135x7. Likewise, what's the functional difference between single row and double row feed dogs? I have both, and both plates, but I think the double was the original. And last, could anyone with one of the machines that has a functioning stitch length mechanism please measure the length of their feed regulating spindle for me? On mine, the spindle threads are intact, but I think the spindle might have been shortened from its original length. I can get barely get to 3mm (no longer than 9/in) and I'm wondering if the issue is that the spindle doesn't push in far enough to rotate the eccentric past that length. (I know I can lock the eccentric at a longer stitch length, but I'm trying to make it work as intended.) The spindle on mine has just shy of 140mm of shaft exposed past the knob shoulder. Pics attached. Thanks! Rick

-

Help on Singer 153 stripped hook saddle screw hole?

rlevine replied to rlevine's topic in Leather Sewing Machines

Thanks for the great ideas! I hadn't seen time-serts before; looks like they have smaller inserts than I remember from using helicoils. They're a bit spendy for this problem, but interesting. In this case, it wasn't as bad as I feared. The hole is deeper than the screw, and singer used a fairly thick washer under the bolt head. Removing the washer allowed threads to catch and hold. I could do the same thing by thinning the ear on the saddle, but once I realized there were healthy threads beyond the end of the screw, losing the washer was the easiest fix. -

I've been looking for a small cylinder arm machine for bag work and found a Singer 153W102 (needle feed ) in ok shape for not too much money. It was badly set up by a prior owner, but I did not find too many surprises as I took it apart. However... I just discovered that one of the hook saddle screw holes in the casting is stripped. Dealing with threaded casting holes is new to me. Can anyone suggest first aid techniques? The screws are healthy, they measure 13/64-32-ish, and the slot in the hook saddle is 7/32" wide. Thanks! Rick