Jholden0

Members-

Posts

46 -

Joined

-

Last visited

Profile Information

-

Location

Maryland

-

Interests

Leather, leather tools, leather dye, leather paint, leather pants.

LW Info

-

Leatherwork Specialty

Watch straps

-

Interested in learning about

Sewing machines

-

How did you find leatherworker.net?

Google

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Jholden0's Achievements

Member (2/4)

-

Thank you both for the response. I actually have a yamata fy810 as well. I tried reaching out to yamata and they actually don't sell parts. Lol. What a sham. Anyway, I found that this machine is a direct clone of the consew 228-r. It uses the same parts. I ordered the parts I needed. Thanks again for taking the time to respond. I'm going to try a roll pin for the time being.

-

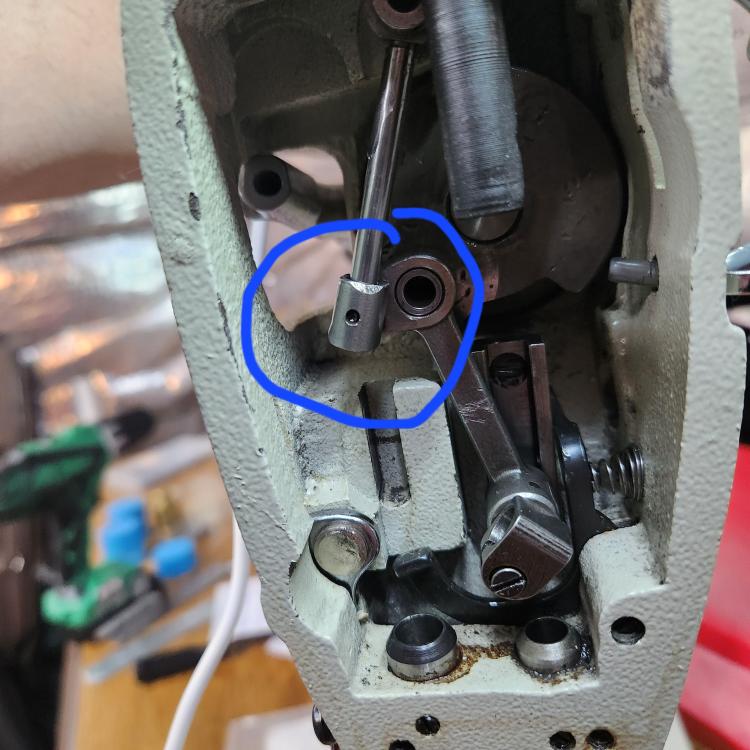

I picked up this Oren post bed wig sewing machine for really cheap. It was missing some parts that I was able to replace. However, there is one part I am unable to source. I know that it's out there, I just don't know what other models and manufacturers utilize the same parts or other clones. I need a thread take up lever connecting pin. It is circled in blue. It looks like it is fine, but the pin that slides into the needle bar crank assembly is actually snapped in half and the pin slides out under tension. Anyone that can help would be extremely appreciated.

-

Yamata fy810 post bed slipping thicker material

Jholden0 replied to Jholden0's topic in Leather Sewing Machines

I apologize for wasting your time, but I just changed out the handwheel with one from another machine. I thought the shaft was moving previously, but it was not. The new handwheel works perfectly. I was trying not to take the machine apart, meaning the internal components. And I didn't have to. Your reply got me thinking and what do you know. It's fixed. Thank you again for taking the time to respond! -

Yamata fy810 post bed slipping thicker material

Jholden0 replied to Jholden0's topic in Leather Sewing Machines

Here is a video clip. Like I said, this does not throw the machine out of timing. Yamata needle bar not moving. -

Yamata fy810 post bed slipping thicker material

Jholden0 replied to Jholden0's topic in Leather Sewing Machines

I was expecting that if the gear was loose, and the handwheel was turned, that the timing would be off. However, that isnt the case. It's very odd. I'll take a video and post it. That may be a better way to communicate my issue. -

I recently purchased a yamata fy810 post bed which is a clone of the original singer 51w. It Works very well except when sewing thicker leather, the handwheel spins but the needle is stuck down in the material even though I can freely advance the handwheel. I think it may be a loose gear on the upper main shaft but I wanted to see if this sounds correct before I take it apart. I originally thought the handwheel may be loosely installed, but upon investigation, I can see that the upper shaft does indeed spin while the needle bar does not move. Does anyone with more experience have any input or suggestions to check before I start taking it apart? Thank you in advance!

-

Consew 226rb-2 presser foot not lifting breaking thread

Jholden0 replied to Jholden0's topic in Leather Sewing Machines

Thanks for the link. I did already adjust that unfortunately. It actually lifts when there is no work in the machine, however once I add leather. Nothing. I'm going to upload a video so that there is a better idea of what is going on. -

I have a consew 226rb-2. I am using 69 thread with a number 20 135x17 needle. I am experiencing an issue that I cannot overcome. Thread keeps shredding and breaking. It is happening when the needle begins to move upward out of the leather as far as I can tell. Initially, I tried a #18 needle and a # 20 seems to have somewhat reduced the frequency of the issue. I have tried the following: new needle, new thread, timing (moving the hook closer, and away, also the needle bar up and down.) Adjustment of the tension upper and bobbin case. One thing I also notice is that the presser foot doesn't really lift much at all while sewing. I tried adjusting the presser foot and walking foot to keep them in timing, I increased and decreased both pressure adjustment screws many times. Is this issue possibly caused by a worn out spring? The machine has to be at least 30 years old if not 50. Does a worn out pressure spring cause anything like this? I am losing it. Thank you for any assistance you can provide.

-

Thank you, I ordered the bushing after validation that it is correct. Also, you are correct about the diameter of my needle bar. Thank you again for your help. I owe you.

-

Constabulary, can you please help me. I thought that the setup I posted above would work. But to my dismay, it was another disaster with this machine. I do have the original needle bar machine. It's 8.5 mm in diameter. I have ordered 8 needle bars total and I am at a complete loss. The needle bar clamp is too large for the 111 needle bar. Do you happen to have the part number for the needle bar you used? I can figure out the bushing hopefully. But this machine is close to being smashed down into scrap. Haha. Please, please help.

-

One other thing I have noticed, is that setting the stitch length to the largest stitch and even the one just smaller than the longest, creates a situation where the stitch length collar seems to slide off. I don't know if this is related.

-

I recently purchased a 29k72 shoe patcher. It is in overall great condition visually and appears to be well taken care of. I installed a servo motor and was able to use the original treadle pulleys to a.run the machine and b. Since there are two sets of pulley, I used them as a speed reducer of sorts. I am having a few issues getting started however. One issue is that the walking/feed foot does not drop consistently and gets stuck even after cleaning and re oiling. It also doesn't fully compress the leather and feed it through the machine. I have tried adjusting the wing nut to lower the foot and also tried adjusting the pressure with the pressure adjustment knob. The second issue is that when starting a stitch, there is a point in the rotation of the crank, where it becomes very hard to turn the cranking mechanism. Videos I have seen online seem to show operators effortlessness cranking by hand. Not only is hand cranking a chore at that one point, the motor sometimes stops turning when using the servo. I know some of my explanations are vague, but does anyone have any tips or suggestions? I can upload a video or add some photos if necessary. Thanks in advance!

-

-

It's actually not a sewing machine part. It's a bushing that I found with very similar dimensions. I'm attaching a photo of it and I'll also add the link. I purchased quite a few from Aliexpress. I had to stick it into the chuck of my drill press and file it down about 1mm. Now there may be something out there that doesn't require filing. However, based on my research, and not having access to a lathe, this was the best option for the 111w needle bar. https://a.aliexpress.com/_mLsNiS7

-

In reference to the needle bar guides, I have found a bushing that is the perfect length and almost perfect diameter. I sanded it down a little to reduce the diameter and it works very well. If you are interested, I can send you the link. It drops into the guide hole on top and wedges itself in place. The inner diameter is prefect as is for the singer 111w needle bar.