AbelJojua

-

Posts

18 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by AbelJojua

-

-

5 minutes ago, CowboyBob said:

Like so many older Singers they are well-built but certain models have specialized parts that will be almost impossible to find like the feed dog & needle plate for this one,you could get the hole welded & redrill it.Or take it to a machine shop & have a new one made.The feed dog in the picture looks like it's still in good shape though.

Throat plate looks a bit rough

-

6 hours ago, Constabulary said:

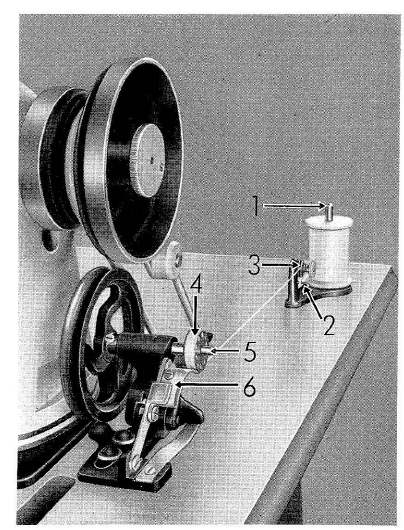

The type of bobbin winder you have usually comes with a spool holder with tension unit - like this:

And it is more comfortable to use compared with the simple machine mounted one that came with the machine ex factory.

Except the hook (same as large hook for 29K / Adler 30-7) and some tension parts (same as for Singer 16 / 17) you will have a hard time finding parts but these machines are so tough you barely will need any when you have it up and running. Look on Ebay. Sometimes folks rip apart machines for parts.

I once needed a new needle bar and found one from a Singer 17 that worked:

https://leatherworker.net/forum/topic/66729-singer-needle-bar-i-could-use-some-help/

So some other bits from other machines will fit for the 34K as well but you have to look them up and maybe compare parts lists but Singer 16 and 17 have certain parts in common with the 34K.

If you haven´t found a manual for the 34K please send me a PM with your email address and I will send you a PDF.

I may also need a throat plate and feed dogs, do u know where I can get these parts?

-

4 hours ago, Constabulary said:

The type of bobbin winder you have usually comes with a spool holder with tension unit - like this:

And it is more comfortable to use compared with the simple machine mounted one that came with the machine ex factory.

Except the hook (same as large hook for 29K / Adler 30-7) and some tension parts (same as for Singer 16 / 17) you will have a hard time finding parts but these machines are so tough you barely will need any when you have it up and running. Look on Ebay. Sometimes folks rip apart machines for parts.

I once needed a new needle bar and found one from a Singer 17 that worked:

https://leatherworker.net/forum/topic/66729-singer-needle-bar-i-could-use-some-help/

So some other bits from other machines will fit for the 34K as well but you have to look them up and maybe compare parts lists but Singer 16 and 17 have certain parts in common with the 34K.

If you haven´t found a manual for the 34K please send me a PM with your email address and I will send you a PDF.

Do u know which bobbins fit ? And price estimate? Many thanks! I’ll sed a pm for the PDF please thank you. I went and test it out yesterday, it produced really nice stitches and moved so well and easily.. I am very happy with it. I think I will purchase. He said he wants €500

-

I think so too, must be one of the smaller heads..it doesnt seem to have the bobbin winder on the side just like stock photos but a replacement winder on the table.. i wonder how hard it will be to find parts if i ever need it.

-

-

-

-

Hi guys, looking to purchase this post bed. Unfortunately the model plate has long faded away. What model is this? And is parts readily available? It has two spool threads so possible twin needle?

Buyers wants €500 for everything, including spare needles bobbins ectOR

a singer 29k171/172 long arm patcher blue machine (no photos yet) and no treadle just machine head.

I have a spare table with servo motor at home.

what do u think?

-

What an amazing and helpful group of people! Many thanks !

-

21 minutes ago, 327fed said:

Yes. Either redrill holes or you might find another pulley with longer center that might extend past shaft enough.

Easiest for me is just redrill. Don’t really mind the extra holes in my table to be honest .. many thanks !

-

Hi guys!

Just converting one of my old industrials with a new servo... is the alignment for the belt and motor a bit off? This alignment right now is as far as it allows me to go to the left.. might need to drill new holes closer to the opening I reckon? And does that belt need to go directly in a straight line down to meet the motor? (It’s at an angle at the moment )

many thanks !

-

Always reading people suggesting heavy duty feed dogs, I thought that applies to thin leathers. Now I that I think of it, it doesn’t make sense to use heavy / med on thin/light I guess

-

Hi guys,

Currently converting my industrial Singer 291U3 into a “light leatherwork machine” (yes, I know I need a walking foot or compound).

I have it fitted with a Jack 513 servo.

With a roller foot and Teflon.

I just need opinions on which feed dog + plate to buy.

I will be strictly sewing garment leather chrome tan.

CKPSMS Brand - #20160LGW+149159 1SET Industrial Sewing Machine Feed Dog & Plate Medium Set Compatible with Singer JUKI Brother https://www.amazon.co.uk/dp/B078MMZ87K/ref=cm_sw_r_cp_api_glt_fabc_SMJ5VWB1GWRMW8R6MY9E

or

Heavy Duty Needle Plate & Feed Dog #149165+143169 for Juki Brother Consew Singer https://www.amazon.co.uk/dp/B0822T1YS7/ref=cm_sw_r_cp_api_glt_fabc_HSZW5MKG46H6PH50QR0T

or

Teflon Coated Non-Stick Needle Plate & Feed Dog for Juki Ddl-555 8700 8500 227+ https://www.amazon.co.uk/dp/B07YQSF7HF/ref=cm_sw_r_cp_api_glt_fabc_D86K52EWTQ18DW6NPM8N

Also what needle size and thread do I need? #69 bonded nylon?

many thanks !

-

Fixed the bobbin case problem , I kept trying to pull it straight out but it just needed a bit of clockwise turning motion to free it up a bit. Fixed it right up. There was a bit of fluff and loose thread in there too. Bobbin case seems to be the most generic universal ones. I also read that I should adjust the bottom feed dog level for leatherwork ?

I appreciate your help !

-

Hi guys,

Recently got gifted this machine, it’s a Singer 291U.

It’s a normal flatbed with a standard presser foot with clutch motor, anybody have this machine and can vouch on its reliability? Unfortunately the bobbin case is stuck and I can’t take it out, so I’ll have to figure out that first.

im interested in swapping out the clutch for a servo and having a roller foot to help it sew well with garment leather and to climb over seams.

I understand that it’s not a walking foot or compound feed but regardless, I want to try make this work.. seeing as I did get it for free

-

7 hours ago, kgg said:

My take on the machine:

1) The instruction manual seems a bit difficult to source but the parts manual can be had at https://www.hendersonsewing.com/manual.asp?page=63 from the Henderson Sewing Machine Company.

2) If I'm not mistaken the machine dates to around early 1930's.

3) The duck tape on the bobbin cover, that's not right indicates the catch level is damaged.

4) Is there a second bobbin cover. Originally there were two bobbin covers depending on the size of needle you were going to sew with.

5) With the way the machine is setup with the hand wheel on the far end indicates it was setup to be belt driven not hand powered and bolted to a cast iron base. Trying to reach the hand wheel to sew is going to be difficult to say the least.

6) Where is the cast iron base, drive belt and flat table top attachment?

7) The adapter, large head screw and hand wheel engaging clutch assembly is missing to put the hand wheel on the side of the machine for hand power operation.

8) I don't see a threading rod for threading the top thread down inside the head.

9) The stitch length could be as simple as the adjuster isn't set properly or worn out internal parts.

10) The overall condition of the machine indicates it was stored in a damp area.

There is a good three part youtube video ( youtube.com/watch?v=95S6IvyPAN0 ) showing the restoration of a 29k 51 which has some slightly different internal parts as outlined in the Henderson linked parts manual this machine. For me, I would pass on the machine unless the price was under $100 and I wanted a project machine to strip down, repaint and replace worn out parts. What is the seller asking?

Just my opinion,

kgg

Thank you so much ! I appreciate your effort and knowledge! I very much rather pay the market price for a good condition one, seller is asking for 350$... he has a newer 29k58 he’s asking for 930$... I just want a machine to use immediately and not have to worry much as I’m a student with many deadlines

14 minutes ago, chrisash said:In the UK there are quite a number of spare parts available for the 29K71 series, some may also work o the 53, these are new or original items. you may find a supply in your country where ever that may be see

https://www.college-sewing.co.uk/parts-by-machine/singer-sewing-machine-parts/singer-29k-71-parts

As Kgg states the handwheel that fits on the front makes life a lot easier and it the needle plate is held on by tape, that could be the sign of a well used and poorly maintained machine.

Thank you for the guidance ! Yes I agree, the tape is a bit suspicious. And the seller wasn’t happy to disclose any real information on the condition of the machine, only that it needs some “TLC”

-

Hi group! I am completely new to this website and leatherwork so thank you for having me! I want to purchase this 29k, however seller doesn’t have much info on it.

it seems that the stitch length is rather long, bobbin winder has parts missing ... anything else that jumps out for you experienced people ? Many thanks !

Pfaff 135 question !

in Leather Sewing Machines

Posted

Hi guys I have a pfaff 335 - 132B/C H3S

can anyone help me break down what this all means please?

is this machine for binding ?

Can it sew leather ?

or is it for fabrics?

thanks !