ThomasBH

Members-

Posts

23 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by ThomasBH

-

Hello, I've fairly recently picked up a Typical GC2605 Cylinder Arm machine specifically for binding the inside/raw edges of backpacks, pouches and some leather items. I'm specially looking for it to bind work pieces that are probably 1/8-1/4" thick using 1" grosgrain mil spec binding tape (5038 style). The machine came with a binder that I think was meant for using very thick binding like leather or webbing, but even using webbing does not produce good results. Here is a photo of some of the binders I've accumulated over the years that I've tried on this machine. Some are not meant for this purpose so I did some jury-rigging with tape to get them to mount, but alas, nothing will produce even remotely acceptable results. Most can't even bind on a straight flat piece. https://photos.app.goo.gl/xFoaS6pCGYHb4sb56 Any suggestions or help would be appreciated! Thanks

-

Hello, I just picked up an absolute steal on a slightly used "Toyoda 1508NH" which is a clone of a Juki 1508, NH but I can't find any information on the internet about this machine. It seems to be identical to the "Titan" branded one but I'm not sure. 1. The rear / non walking foot is very wobbly even when tightened...the hole is possibly too large? Should I be fine ordering regular 1508 parts? And how can I determine if its the foot or the piece the foot attaches to? 2. The needle size listed in the manual is 190 (and for actual Juki 1508 NHs) but the retailer / previous owner has 135 x 17 needles installed, which would be for the regular N version, not the NH version. My initial idea is the hook timing may have to be altered to work properly with the 190 size of needles...then I was thinking, maybe this machine is actually just an N version despite the metal plate riveted on the side. 3. There is a large plastic wheel with 1-6 settings on it on the top right...I think this is for adjusting the height of the walking foot? Can anyone confirm? I'm in Canada and any part sources or tips and tricks on this machine is appreciated. Thanks!

-

Pfaff 145 H3 outer pressure foot does not raise

ThomasBH replied to ThomasBH's topic in Leather Sewing Machines

Solved! I guess that a "partially" compatible foot (cheap Aliexpress crap) must've knocked the other foot out of timing so the foot wasn't arriving at the exact time as the needle reached the bed, and only when it reaches at the same time does the 2nd foot actually raise and lower when the inner foot is at the bottom. It has an interesting mechanism for sure! -

Pfaff 145 H3 outer pressure foot does not raise

ThomasBH replied to ThomasBH's topic in Leather Sewing Machines

Thanks for the suggestion, but no, even with no feet attached watching the machine cycle the outer bar barely moves up and down at all, just a mm or two. -

Hello, My Pfaff 145 was working fine for months, then all of a sudden after changing out feet the outer foot will not raise. Only the hand/knee lift will raise it now. If I look real close it moves about a mm when the inner presser foot is at BDC (bottom dead center) I've puzzled through all of the adjustment guides on the 1245 as well as google searches and can't find anything. Any suggestions? Thanks

-

Pfaff 145 Right Angle Binder Quick Detach on Plate?

ThomasBH replied to ThomasBH's topic in Leather Sewing Machines

Thank you kgg, i'll look into that company! -

Pfaff 145 Right Angle Binder Quick Detach on Plate?

ThomasBH replied to ThomasBH's topic in Leather Sewing Machines

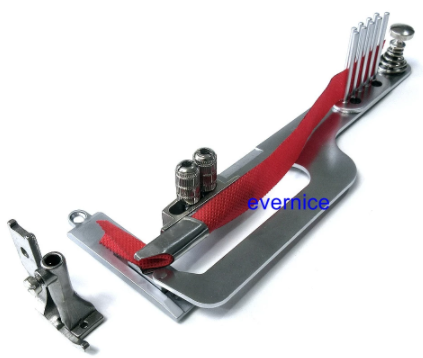

Thanks for the suggestions. I have this exact model of binder, same as you linked me. It came with a 24mm like the cutex one and it is too tight to fit the 5038 grosgrain well. Its possible that that style of binder is the way to go, just a different one that is larger. Also I would need to go up to 8mm. Also of note, the outer foot did not fit my 145, I got it to fit after filing down the top sides and it still doesn't fit well. The C shaped top was not wide enough to fit my machine. I also don't like this setup because it takes far too long to change over from the standard setup. I will be using this when I have to bind a bunch of stuff at once, but often I'm just binding small items in-between regular sewing when making bags. -

Pfaff 145 Right Angle Binder Quick Detach on Plate?

ThomasBH replied to ThomasBH's topic in Leather Sewing Machines

Hello, Thanks for all the detailed replies! 1. By D shaped feed dog covers I am referring to the half-moon or D shaped metal feed dog cover than is common on many newer lightweight industrial machines. 2. I am using 1" mil-spec grosgrain (5038 to be specific) https://www.rockywoods.com/1-Grosgrain-Ribbon-Mil-Spec-Style-5038 3. The inline binders I have work fine but not with thicker builds or around curves. I'm looking at binding the inside of bags or shoulder straps that can often be 6-8mm thick. 4. In my ealier searches of this forum I didn't find what I was looking for, perhaps becuase I was just looking for Pfaff binder setups. Here is one from this form with pretty much what I'm looking to do: 5. The existing right angle binders I have that are meant for that top style of feed dog cover do not work, even if I drill holes because the L bracket will not be close enough to the needle. Basically in the bottom right of this photo you can see that the vertical plate/guide after the binder is too close with any normal feet. The idea is I want to keep my standard walking feet and just swap out the plates. 6. Here is a video of a guy with a Juki with pretty much exactly what I'm looking for. Thanks again! -

Hello, I'm looking to get a single fold, right angle binder 1" in size that just mounts to the bobbin cover plate. I would like to use the standard feet for the machine (double outer feet) and be able to just swap the plates out. A swing away style would also be fine. Something like this, only would not require swapping out the feet: https://www.ebay.com/itm/292096884215?_trkparms=amclksrc%3DITM%26aid%3D1110006%26algo%3DHOMESPLICE.SIM%26ao%3D1%26asc%3D238901%26meid%3D7245e542c0774f9bb307900b4d433d75%26pid%3D101113%26rk%3D1%26rkt%3D12%26sd%3D122464199943%26itm%3D292096884215%26pmt%3D0%26noa%3D1%26pg%3D2563228%26algv%3DDefaultOrganicWeb%26brand%3DUnbranded&_trksid=p2563228.c101113.m2108 I already have the synchronized binder attachment with the binding feet and feed dogs, but it simply takes too long to change over. I have seen a number of small businesses on Youtube with this style on similar machines like the Juki 563. I have a couple of right angle binders from other machines that are designed to attach to those D shaped feed dog covers and investigated the idea of tapping new holes in one of my bobbin plates, but the part that screws to the plate would prevent the actual binder from ever getting close enough to the needle to effectively capture the binding, eg it needs to be further to the left. I also emailed Tennessee Attachments, but they did not get back to me. Any suggestions? Thanks!

-

Pfaff 145 h3 reverse stitch length shorter than forward

ThomasBH replied to ThomasBH's topic in Leather Sewing Machines

After much more fiddling and a local sewing machine technician stopped by I seem to have gotten my 145 into a state that I'm pretty happy with. While the forward / reverse stitch length was the most noticeable issue when I first received the machine, after additional testing the inconsistent tension was of much more concern. My forward and reverse stitches are still not consistent, especially if I change the stitch length. (I have decided to just leave it at '2' for most purposes where I have adjusted it to match fwd/rev for at least 4 or 5 stitches) The tech found four issues: 1. The hook/bobbin assembly was not fully seated in its slot (maybe a couple of mm higher than it should've been) This caused this part to wobble: 2. The hook/bobbin assembly position needed to be rotated slightly(using the right hand screw that allows some horizontal adjustment) 3. The throat plate had been damaged/enlarged where the hook/bobbin case slots into it on the underside, this caused loops to form at the wrong time. Here you can see the closest throat plate with some damage/odd shape and the new binding throat plate in the rear of what it should look like. 4. Micro burs / sharp edges on some components Thank you all for your help, much appreciated. I have tried to include lots of photos and descriptions to help any future users facing issues. Feel free to DM me if you need any help yourselves. Also, for those interested you can get very cheap binding sets to have a cylinder arm style synchronized binder, this would work on a 145, 545 and 1245. https://www.aliexpress.com/item/1005003451959950.html?spm=a2g0o.9042311.0.0.14334c4d3mdpTs -

Pfaff 145 h3 reverse stitch length shorter than forward

ThomasBH replied to ThomasBH's topic in Leather Sewing Machines

-

Pfaff 145 h3 reverse stitch length shorter than forward

ThomasBH replied to ThomasBH's topic in Leather Sewing Machines

So I've spend some time fiddling and reading manuals / watching youtube videos. 1. I adjusted the needle bar height to be the exact height of the outer walking foot so that it wouldn't collide, but this caused other issues, namely the hook point did not meet the scarf to grab the upper thread properly. Made some terrible sounds and broke a needle. I could not find a manual for the 145/545 mentioning the distance the needle bar should be at bottom dead center (BDC), but in a 1245 repair manual it mentioned 15mm. It was set to 15mm before I made these adjustments, so I just returned it back to 15mm. I am assuming that this aftermarket welting foot is the issue and am hoping the proper Pfaff foot doesn't strike. Can anyone confirm what the 145 H3 needle bar height should be set to? 2. Watching this video (also for a 1245) it states that the needle hook should be right in the middle of the scarf. My machine seems to be slightly lower than this. It mentions the needle bar should be at BDC, then 2mm up for the hook to meet the scarf. Mine is probably 3mm up, however it seems to be working fine. I also notice that the hook also hits and deflects the needle slightly, maybe 0.5mm. I see in another Cechaflo 1245 video he has his 1245 hitting the scarf slightly. Should I be concerned with this? Should I adjust it to be exactly 2mm and not touch the scarf? 3. Relating to both 1 & 2, my machine is supposed to be using the 134-35 needles but the previous owner gave me about 10 packs of 135-17s, which are about 1mm longer. So maybe he had timed the machine for the longer needles? Maybe because they were more available? I am going to try using one of these to see if it works any differently. 4. Will any of the above adjustments actually affect the forward to reverse motion of the stitch length? -

Pfaff 145 h3 reverse stitch length shorter than forward

ThomasBH replied to ThomasBH's topic in Leather Sewing Machines

Johnny, thank you for the help! My machine is a 145 H3 6/01. My needle is definitely new, I'm using the 134-35. I have also ordered a variety of feet (binding, regular and zipper) but alas, they are taking weeks to arrive. I'm definitely going to be trying all of the sections you mentioned, however it is very "dense" filled with jargon I'll have to look up, so it will take me a while. Even 'hook point' or 'centerline of the needle' are confusing to me. I will keep reading and look some of these terms up. I will send you a PM for the manual. -

Pfaff 145 h3 reverse stitch length shorter than forward

ThomasBH replied to ThomasBH's topic in Leather Sewing Machines

Thank you very much Johnny. Reading point 9.2 it mentions the needle bar should not strike the raised foot. My outer foot does strike the needle bar when raised in this situation. Should I attempt to raise the needle bar? I think this will cause issues with the hook timing unless I had a longer needle. I'm using 134-35 needles, but this machine also came with a lot of 135-17. Also, the only foot it came with is a welting foot and it appears to be after market, which is why it may be striking the bar. -

Pfaff 145 h3 reverse stitch length shorter than forward

ThomasBH replied to ThomasBH's topic in Leather Sewing Machines

Thanks Michiel. Unfortunately I have not been able to located a service manual for the 145. Does anyone know where I can download one? -

Pfaff 145 h3 reverse stitch length shorter than forward

ThomasBH replied to ThomasBH's topic in Leather Sewing Machines

After much more fiddling I now think that I'm just chasing my tail. Every non-eccentric screw adjustment seems to affect the relationship between the forward and reverse stitch...the foot height adjustment wingnut and stitch length all seem to affect this in a large way. So if I adjust the eccentric screw to have forward and reverse perfectly match for a stitch length of "2", it will be off within just a couple of stitches if I adjust the foot height wingnut or the stitch length. Is this normal? Do other non-Pfaff machines do this? -

Pfaff 145 h3 reverse stitch length shorter than forward

ThomasBH replied to ThomasBH's topic in Leather Sewing Machines

Thank you so much! This completely solved my issue, it ends up the previous owner had placed that tapered nut upside-down on the reverse lever! Such a simple solution after pouring what seemed like 5+ hours of punching holes in paper! For reference for anyone with this same issue, the attached photo shows the nut in the correct orientation. still a little fine tuning to do with the eccentric to get it perfect, but it is already almost perfect even ten stitches backwards no matter the stitch length. Thanks for everyone’s help! -

Pfaff 145 h3 reverse stitch length shorter than forward

ThomasBH replied to ThomasBH's topic in Leather Sewing Machines

Still cannot get this to work. I can’t even get it back to the best point I had it at last night. I feel like I have done hundreds of small adjustments. I can easily get it to that “no movement 1mm above dead bottom centre on the feed dog ” but this doesn’t help. Neither does doing incremental changes in either direction. Eventually if I keep going the thing starts going in reverse, but never matches forward and backward stitch length, especially at the shorter lengths. Lowering the stitch length seems to make the issue exponentially worse. Is there anything else that may be out? Timing? -

Pfaff 145 h3 reverse stitch length shorter than forward

ThomasBH replied to ThomasBH's topic in Leather Sewing Machines

Thank you all for your replies. I will try halving the stitch length, which is a bit of guess work on this machine (it’s not entirely clear when you’re at certain lengths) then adjusting the eccentric screw in micro-adjustments. I’ll post my results after some fiddling. -

Pfaff 145 h3 reverse stitch length shorter than forward

ThomasBH replied to ThomasBH's topic in Leather Sewing Machines

After fiddling with the eccentric screw in micro adjustments for about 3 hours I found a decent enough balance that it will at least match the stitch length closely for about 8 reverse stitches before going off, so this was promising…however this was all done at the longest stitch length and as soon as I reduced the stitch length it is completely off! I will keep fiddling to see if I can fix this for any stitch length. Any tips would be appreciated! -

Pfaff 145 h3 reverse stitch length shorter than forward

ThomasBH replied to ThomasBH's topic in Leather Sewing Machines

Since I got home I’ve been fiddling with the eccentric screw. I’m finding it difficult to get it to stay put after getting the feed dog to not move in the needle down position because the two screws aren’t exposed until you rotate the hand wheel a bit. I’ll keep trying! Thanks for the video and reply! and looking at this piping foot in comparison to the parts catalogue and it must not be original. Here you can see it striking the needle bar. -

Pfaff 145 h3 reverse stitch length shorter than forward

ThomasBH replied to ThomasBH's topic in Leather Sewing Machines

Thanks for the detailed reply! 1. I will try again when I get home from work, but trying yesterday the stitch length screw seemed to bottom out around the “2”. Like the screw in the reverse leave cannot go to zero. 2. I will take some photos later today, but basically the needle bar smashes into the outside of the welting foot and actually bends it out of the way which causes the screw to loosen, not to mention probably damages something. This only happens on very thick material, such as ~1/2” foam. -

Hello, My “new” Pfaff 145 has a couple of issues, namely the reverse stitch length is significantly shorter than the forward. Any tips of fixing this? I found this forum thread, but the answer was not listed: My other two lesser issues are: 1. The screw holes in the bobbin cover/plate don’t seem to work with the thumb screws I have from my Mitsubishi DY350 binding attachments. Is this not a standard size, or should I order a new plate? (Anyone know of a decent priced North American supplier of these parts? I’m in Canada) 2. The needle bar will strike the outside foot on thicker fabrics. Unfortunately this machine only came with a welting foot and I do not have other ones to test on. Thanks!