Southerngunner

-

Content Count

91 -

Joined

-

Last visited

Posts posted by Southerngunner

-

-

7 hours ago, Wizcrafts said:I own a Singer 168g101 and love it for sewing patches onto vests and hats.

What is the difference between the g and the w models ?

-

After a year and a half of using my other machines I am comfortable enough to find my way around my first post machine. I still have a lot to learn but I'm not afraid to tear into one now and troubleshoot it. Thanks to the very knowledgeable and helpful folks on the forum, I'm sure that I will have some dumb questions before it's all said and done

-

5 minutes ago, dikman said:A walking foot post-bed for $250! No mistake, I reckon you've done well! Just ditch the clutch motor and you'll be laughing.

As soon as I get it here and cleaned up the servo will be on the way if it doesn't need and other serious repairs

-

My dealer still has this old Singer 168W-101 that I almost bought 1-1/2 years ago. I'm pretty sure that I don't need it since I already have ,a cobra 26, consew 206 rb -2, and a econosew 18"arm 29 k copy.

I gave him a call today and he said that I could have it for $250.00 with the table clutch motor and light and bobbin winder.

I'm supposed to go get it next week, he said he is tired of looking at it.

I hope I'm not making a mistake.

-

My class 26 has the pan also, I believe it is a catch pan to keep excess oil from your table

-

2 hours ago, LinkAiris said:Hi Terry, Congratulations on your potential new purchase! The Singer 168w 101 is a classic industrial sewing machine, known for its durability and heavy-duty performance. Here are a few points to consider regarding the price and overall investment: Price Evaluation: $400 for the machine, table, and light, especially after a servicing, sounds like a reasonable deal for an industrial machine of this caliber. Adding a servo motor for around $125 brings your total to $525, which is still quite competitive for a reliable machine that can handle heavy materials. Condition: Since the machine has been serviced and will be demonstrated as working properly, you can have more confidence in its condition. Look for signs of wear and tear on key components like the needle bar, presser foot, and feed dogs. Even if it's in good shape, minor parts might still need replacement over time. Clutch vs. Servo Motor: Clutch motors are robust and powerful but can be loud and less precise. A servo motor, on the other hand, will give you more control, is quieter, and generally more energy-efficient. Upgrading to a servo motor is a smart move, especially if you're new to sewing machines, as it offers better speed control and less noise. Historical Value: Given that it's a 60-plus-year-old unit, it also has some historical value and craftsmanship that modern machines might lack. Many vintage sewing enthusiasts find these machines to be well worth the investment. Additional Costs: Consider any potential costs for accessories, needles, and spare parts. While Singer parts are usually accessible, it's something to keep in mind. Usage: Think about what you'll be using the machine for. The 168w 101 is great for heavy fabrics and leather, so if that’s your intended use, it’s a solid choice. Overall, based on your description and the price, it seems like a fair deal, especially after ensuring it's in good working order post-service. The servo motor upgrade will significantly enhance your experience. Just make sure to see it in action and confirm everything is functioning as expected before finalizing the purchase.

Thanks for your reply, I passed on that machine but it is still at the shop 1 1/2 years later. Every time that I stop in I'm tempted to ask about it just because it a cool vintage machine. But I am actually thinking of a cowboy 4500 or cobra class 4 to do more than my class 26 cobra can do, I also picked up an enconosew 18 inch arm shoe patcher copy of the singer 29 series..

-

2 hours ago, dikman said: Yep, I'm the same, much to my wife's dismay. A friend recently asked if I could have a look at a faulty dropsaw that belonged to her cleaning lady. Turned out that one of the carbon brushes had broken off and wasn't making contact with the commutator. Normally this would mean a cheap saw like this would just be thrown away, but I have a selection of carbon brushes salvaged from trashed motors so it was a simple job to grind one to fit.

Yep, I'm the same, much to my wife's dismay. A friend recently asked if I could have a look at a faulty dropsaw that belonged to her cleaning lady. Turned out that one of the carbon brushes had broken off and wasn't making contact with the commutator. Normally this would mean a cheap saw like this would just be thrown away, but I have a selection of carbon brushes salvaged from trashed motors so it was a simple job to grind one to fit.

I'm olde school and enjoy fixing things (I've got quite the reputation as a "fixit-man" at my wife's church

).

).

McGyver is alive and well, us old guys are packrats and fixin fools

-

3 hours ago, GerryR said:I personally like the natural wood and its contrasting with the rest of the machine. (I did mine like that.) That is some really nice work! Now its time to enjoy using it.

Thanks, I kinda like the look myself. I bought the servo motor, pullys,belts, and 1 sheet of 3/4" plywood so I'm in it under $300. Everything else I already had and it has been paid for a long time ago( I don't throw good stuff away) so I don't count it in the tally. Including the cost of the class 26 the total is well under $1600 and of course all of my time is really cheap.

-

Maybe later but for now I am tired of messing with this thing.

-

-

-

I built a drawer and a pull out shelf.

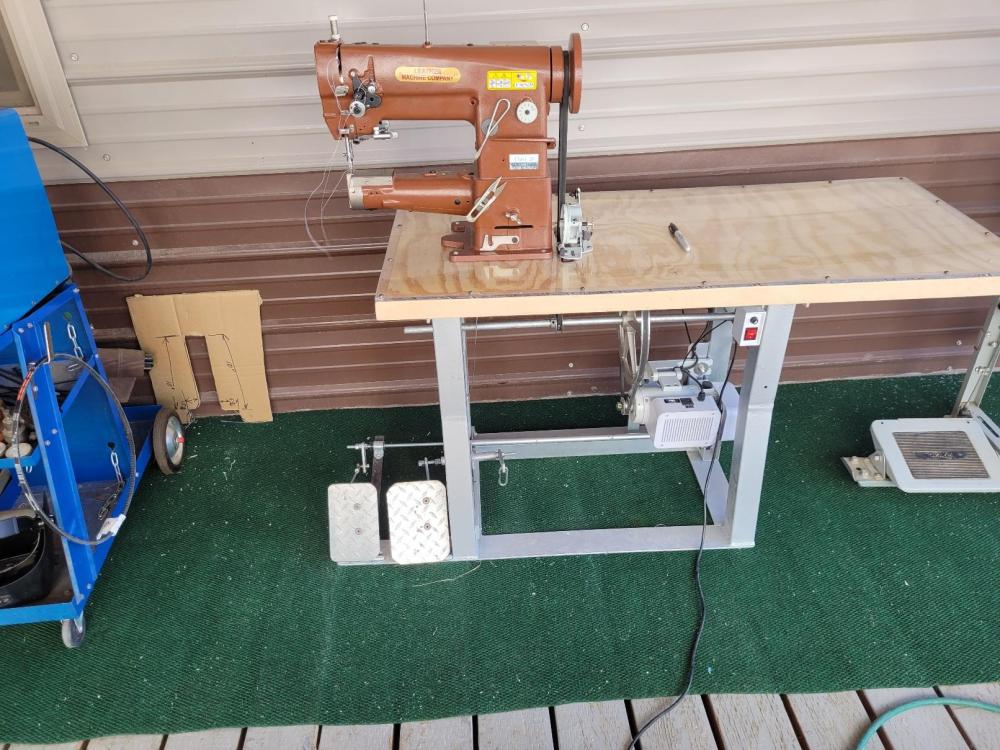

I won't be moving this much as it weighs a ton , but it doesn't shake,vibrate, or move around and the machine is solid and smooth when running

-

-

Everyone can't afford to drop 3 to 5 grand or more for a sewing machine. I bought one when I finally decided that hand stitching wasn't working any more. I gave it to my daughter for a no power required sticher.

It took a lot of tinkering to get it to work but if you don't push the limits its a good inexpensive option to sew with.good luck.

-

10 hours ago, BliksemDonder said:@TomE I feel you. I will be welding up the stand for my bell skiver tomorrow and my mig has not been used for a few years. Propbably take longer to clean and set up my welder than the project that needs to be done.

@Southerngunner Nice sewing table you got put together there. The satisfaction of creating something from an idea to fulfill a need is priceless. I am spending way more time fabricating bits and pieces to support my leather craft than spend doing the craft in the first place!

Thanks for the reply. I haven't touched my welder for a few years also, but after a couple passes on scraps it started coming back to me.

I plan on statring to building a side cabinet today and then I need a light. I did make my own thread stand however.

My wife thinks I'm nuts to take time to build something that I could order for $15.00.

-

On 4/24/2024 at 3:34 PM, TomE said:That’s a nice piece of work! Wish I could weld like that.

Thanks, I was a welder/ fabricator/ heavy equipment mechanic for 45 years. It felt good to do some welding after a couple years of not working with metal.

-

6 hours ago, GerryR said:Very nice!! Looks like with that speed reducer you can make a stitch every 30-days or so

.

.

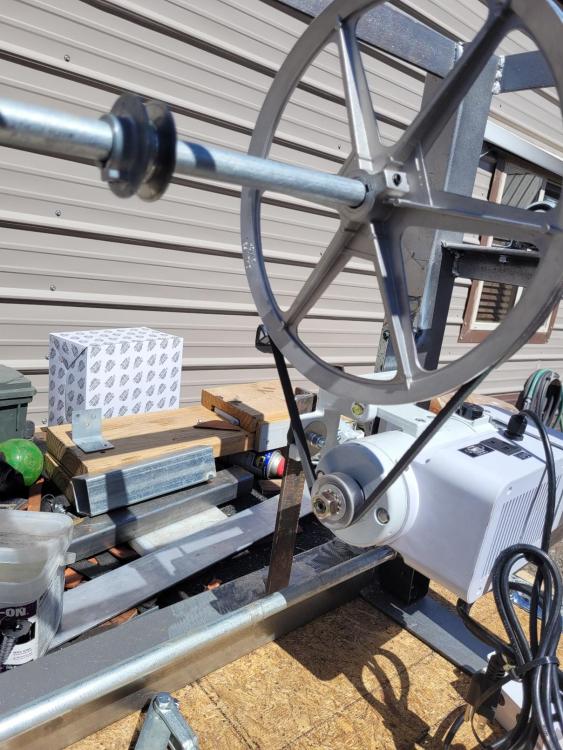

Yep I can turn up the adjustments on the servo for speed and still be able to go 1 stitch at a time when needed.

-

Yes that is a factory K -leg table next to it. I just wanted to prove to myself that I could make a usable table.

-

Well here it is so far, I still have to make a side cabinet for storage . At this points it is usable the way it is.

The top is 2 pieces of 3/4" plywood glued and screwed with a border of 3/4" Birdseye Maple. The replaceable top is. 1/4" Lexan ( an old windshield from a Yamaha Rhino)

I set up a 12" and 2" pulley system and a Consew servo motor to drive my Cobra class 26 at a controllable speed with gobs of torque.

Most of it was built with stuff that I had hoarded because it was to good to throw out.

Comments are welcomed

Here is a couple more pictures

-

-

-

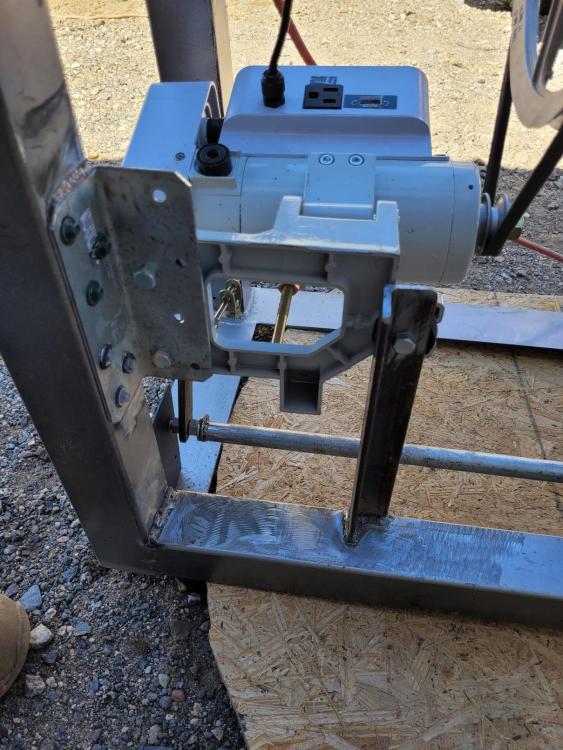

The go pedal has a built stop to keeping from going over center and sticking the motor on. I still have to work out the presser lift pedal and linkage.

-

-

Here is another update on my home made table for my cobra 26. I did a test fit for the machine and pulleys to see how it all works.

The first picture is the way the machine will mount through the angle, the 2x4 is slightly thicker than the table will be.

It works great, I'm happy.

The 12"and 2" pulley setup really increases the torque and keeps the speed where it is completely controllable even on the 3rd setting on the servo

I don't think that I can pass this deal up.

in Leather Sewing Machines

Posted · Report reply

Thanks for the explanation.