Irishleather

Members-

Posts

16 -

Joined

-

Last visited

Profile Information

-

Location

Washington

-

Interests

Designing, welding, sewing stuff together, sewing machine repair.

LW Info

-

Leatherwork Specialty

Newby

-

Interested in learning about

Table top tools and equipment

-

How did you find leatherworker.net?

Looking for information on tools

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Irishleather's Achievements

Member (2/4)

-

1925 Harley JD Seat Restoration

Irishleather replied to Irishleather's topic in Motorcycles and Biker Gear

Here it is done, pretty much. He darkened it more and kept working the nose (more curled). These earlier (24,25?) seats only have a partial back, as seen in the picture of the frame. So the first layer of leather is kind of the bucket. This seat has boiled (felted) wool (from an old blanket) and a heavy linen weave to protect the wool. (?) The top leather layer is cut a little bigger to get the sling and fit right before the stitching, final trim, and burnishing. I would have done the wet and weight trick with a carefully drawn stitchline, then would have definitely sculpted my edge better. But my guys don't like "hold-ups". lol (or listening to granny) The motor is a 3D print, but since then, he has bought an original motor to rebuild. He didn't grow up with guys doing this kind of stuff (mostly the women are the mechanics around here). But from the time he was a little kid, he loved to make "props". He carved wood stalks and used metal pipe and probably sewing machine parts to make a pretend rifle. Once, he made a rifle so real that we quickly bought it off of him before he headed back to town, where he lived. So, for the seasoned, this might not be up to par, but by the time he is done, he will know every detail, and it will be amazing. -

1925 Harley JD Seat Restoration

Irishleather replied to Irishleather's topic in Motorcycles and Biker Gear

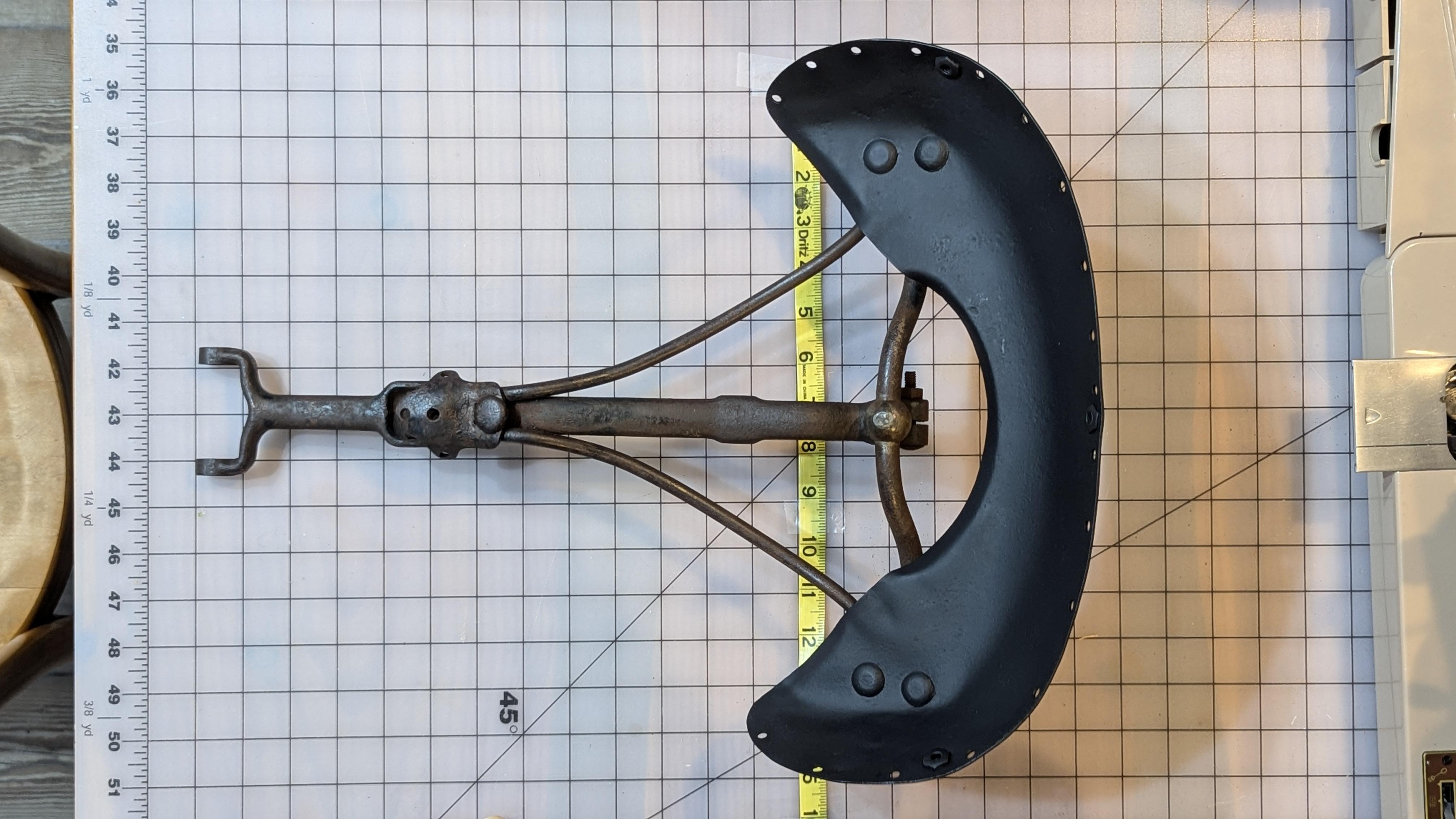

Thanks! 6-strand linen! OK, this might be a test of his patience. Here is the frame and the first layer experiment. Found better rivets today, so those will be changed out. -

I am helping my grandson build his Harley long-nose seat. At this point, he will be stitching by hand, two layers of veg-tanned leather with pre-drilled holes. I'm ready to order the thread. I'm thinking waxed four-ply linen .8 to 1mm? But I'm not finding it where I can get it sooner than next year. And not sure if that thread is the best in this situation. Any thoughts?

-

Singer 51 W 25 Stitch length?

Irishleather replied to Irishleather's topic in Leather Sewing Machines

I was looking at Wheeler & Wilson nose parts and I think those lower tensions with the take-up spring might work. The passive tension up high doesn't worry me. It's the lower tension because it is missing parts. I have a bin full of old new stock springs and recovered tension parts. I'm grateful you found the case/cap tension spring. I will order those. Then Frankenstein the lower tension until a Wilson Wheeler or other complete tension with take-up spring (with or without the actual spring) shows up. There were a few on eBay, but already sold. I have a friend that collects then, so I'll be able to really see if that is an option. I'm excited it will take longer stitches when I get the parts. -

Singer 51 W 25 Stitch length?

Irishleather replied to Irishleather's topic in Leather Sewing Machines

Thank you so much!! I appreciate your time on this. Going to look now that the rain have driven me inside. -

Singer 51 W 25 Stitch length?

Irishleather replied to Irishleather's topic in Leather Sewing Machines

I don't think it's all there, judging from the list of parts and pictures. There is a round piece between the plates that looks like it is for part of the spring to move on. I need to just try some things, even something semi-modern. -

Singer 51 W 25 Stitch length?

Irishleather replied to Irishleather's topic in Leather Sewing Machines

Ya, that spring didn'y work. lol I look for a picture on a parts list. Hopefully. -

Singer 51 W 25 Stitch length?

Irishleather replied to Irishleather's topic in Leather Sewing Machines

I'm comfortable with changing needle bars and readjusting the timimg. Why not just raise the bar for a longer needle? I have a lot of different needles for somewhat old sergers and just old unwanted stock from a boot maker in Eastern WA. I will choose the needle (sort of) for the reasons you did and maybe only need to raise the bar. Even more challenging.... I wonder if I found a pressure-foot bar that fit... if I could then upgrade to a roller foot? Right now the needle for my 23-17 appear to be the right size, too . Which would get me into a size 18 needle. I tried a 22, the timing was good, but the needle slid down the upper left-hand side of the hole. However, with a flat-side instead of round, it would put me more towards the center ( I think). Here is a spring I might try.... -

Singer 51 W 25 Stitch length?

Irishleather replied to Irishleather's topic in Leather Sewing Machines

I am going to order the feed dog set. The stop on the lever was the first to be loosened. So the feed dogs on it make their full sweep. But I like your idea for getting a longer stitch. The bobbin cap is relativily new, I think. But no way was it going to lay pressure on the thread. So I took it off and thought i could gently bend it as I have before. But this one was brittle and snapped right away. Oops. Before I order needles; Does any of the changes you made change the needle type? And what needle do you use? I'm was hoping to use an 18, but I've only seen 14s in needle I thought was the right one. 130x3 or 128x? flat side or round shank? Or just use whatever works with fit and timing? The W&W face plate doesn't show it has the take-up spring, I have a bunch of springs to play with and thanks to you a picture, at least, to cofirn the spring and I can see the type, if it is the same as mine. Mine, I have taken apart. I think every thing but the spring is there. I'll order the dogs and play with springs. I'm wondering if I can upgrade the tension, so I'll grab that box and dig around in that, too. Thanks! -

Singer 51 W 25 Stitch length?

Irishleather replied to Irishleather's topic in Leather Sewing Machines

Checked out your restoration on the 51W100 wow! And you got longer stitches. Amazing work!!! -

Singer 51 W 25 Stitch length?

Irishleather replied to Irishleather's topic in Leather Sewing Machines

Thank you. Everything moves and works now. A little "Goo Gone" and parts started to move better. The feed-dogs use up the slot in the plate so thats good, still small stitches, but that is the design. Shoping for needles, looks like they are available and unfortunately small which tells me this machine is light to medium fabric. I was hoping to do canvas and light leather bags. I broke the bobbin case thread tension piece, I think I located one that might work. I have containers of parts and nothing with that spring. lol I also see there is no take-up spring. It shows one on the 72W (Which Bob Kovar recomended looking at [thanks Bob]). I have a container of springs, too, we'll see. I'm wondering why I can't just modernize the last tension. Thank for you help! The manual was perfect! Thank you!! -

Singer 51 W 25 Stitch length?

Irishleather replied to Irishleather's topic in Leather Sewing Machines

OK, I got it moving everything including the feed dogs. I'm using a needle from my Singer 17-23. I think it might be a good match, it is with the hook, but it is pretty sunk before the teeth go below the plate. So that sounds like a feed adjustment. So far the stiches are aroun 9 to an inch. I am afraid that is too small for leather. Which could put me in search of a post bed with longer stitiches. -

I just picked up a Singer 51 W 25, I think. The badge is gone. What I am asking about: I see a lever to the right that I thought would increase the stitch length, and the lever does move a rod along a slide changing, maybe, the feeddog shaft? Not sure what I am looking at yet. Is that what that lever is suppose to do? Also I broke the bobbin case tension spring, thought I could coax it to put pressure on the thread, since completelty tight did not. But, ya, that didn't work. Works on newer stuff. So I hope one is coming from an eBay seller, although it didn't identify that machine. I saw on on here, but nothing that might speak to a similar machine so I can figure out the stitch regulator, if that's what it is. Advice? Beautiful old table! I put pictures in, then thought to choose a better one, now it won't let me load any. lol There they are.

-

Irishleather joined the community

-

bench grinder for burnishing

Irishleather replied to SonderingSusan's topic in Leatherwork Conversation

I know a few years have gone by. I am looking to sand and burnish leather, too. But because I work with industrial sewing machines, I wondered if the "servo" motor made for sewing machines would work? like this one? This is shipped by Amazon: https://www.amazon.com/dp/B07XB9D1L6/ref=redir_mobile_desktop?_encoding=UTF8&aaxitk=36db6e8e52797bb897763410eaf47ae6&content-id=amzn1.sym.7e9cd8c2-888c-46c4-82d2-714b2b703021%3Aamzn1.sym.7e9cd8c2-888c-46c4-82d2-714b2b703021&hsa_cr_id=9755496630001&pd_rd_plhdr=t&pd_rd_r=4023fb89-9de5-44a7-8a53-11d5b5a140a7&pd_rd_w=maWQc&pd_rd_wg=CHy7u&qid=1675011135&ref_=sbx_be_s_sparkle_lsi4d_asin_1_img&sr=1-2-9e67e56a-6f64-441f-a281-df67fc737124