Jianis

Members-

Posts

27 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Jianis

-

-

My reserve helmet liner needs some tidying up. I consider using real leather. Do you have any suggestions about the kind of leather and thickness? I made a forum search but did not get any results. Thank you in advance

-

Thank you. I sure get your point. It seams to be a very big price difference !! The machine in question has only 5 mm distance between the needles. I guess I have to wait until a more suitable machine comes for sale

-

Thank you I only should use it for the double needle. I have got a Singer 111 W 152, a Pfaff 145 H2 with extra piping and zipper feet, a really heavy-duty Adler 4-10, and a small collection of lighter machines. The machine in question is coming with a rather small 5mm dinstance between the needles so I guess I have to search out if it is possible to change to a wider system

-

Hello everyone. There is a Pfaff 142-6A S double needle machine for sale. I am considering buying it as I am making a leather interior for my classic car. Does any of you have information and advice if the machine is good enough for leather? and points that I should be aware of. Thank you in Advance.

-

Thank you . A lot of usefull information in one document. Back in the 70s I had the theory in college and I even got a deviding head and 2 sets of gear cuting discs to experiment on my Myford lathe with milling attachment. At the time I made two gears on coper disks and then I forgot all about it. Jianis

-

Thank you ! Lots o useful information. thIt is a German machine so it should be metric. I am a couple of thousand miles away from home so it will be some months before I can work on the machine again! The gear has some 50 teeth.I can eventually calculate the number of teeth of the smaller gear measuring center to center between the the gear itself and the center of the back-gear bracket. Then find out the kind of gear and go further…. Jianis

-

It has got only the big gear and a bracket for a shaft (?? ). Now that you mentioned it I might be able to find some parts in the future. At the moment I cannot do anything as I am away for a few months so I only can do some research for finding parts. Helical gears is a good idea if you have the means to make the needed setup. In the mea time I will be *torturing* the forum with questions about a totally worn out Singer 29 D 60 that I just pulled out of the cellar of my summer address ( 35+ years ontheven waiting list ). Do you have any photos or relative information on the back gear that was used by the Adler. Thank you! Jianis

-

For now and till I get some parts for my Singer 111W.. it will stay as is and I will work on some minor issues dat need to be solved. Jianis

-

Thank you Constabulary The machine is massive and heavy. I got it only to use the frame and foot wheel to set up my 111W Singer, I did not know the size !! It is equipped with a huge clutch motor. I did not expect it to work but it does it only needs some work on the thread tension spring and the bobbin case. It has a max stitch of 11 mm. Jianis

-

Hello again. One more question: Is anyone familiar with the Adler 4-10 industrial sewing machine? I am searching already for some time but there is nowhere any information. Jianis

-

Thank you Uwe!

-

Tor I am new on working on sewing machines so I first have to find information how to lower the feed dog. I see we have the same interest on vintage Volvos! Jianis

-

Thank you Tor. I will follow your advice and lower the feed dog see if it makes a change. I used thick colored thread on top only to schouw how I thread the machine (Costabulary asked ) . I am using Tex 70 polyester thread and new 110/18 needles Jianis

-

Singer Age by Serial Numbers Slide Chart

Jianis replied to Gregg From Keystone Sewing's topic in Leather Sewing Machines

Grat Now I can date my 111-W-152 back to 1951 -

Uwe Thank you for your detailed search for me! It is hard to say if I have the right parts as I have no dedicated parts book. They are all marked as Pfaff parts. The lever that activates the thread tension release pin is missing and its screw is broken but for me, it is not essential at the moment I will attend to it later.

-

-

Thank you Glenn! I use the thread that came with the machine I believe it is # 92. The upper one on the photo is a thicker one that I only used to show the thread path. I still have to get some different sizes of needles. At the moment it uses 134-35 110/18

-

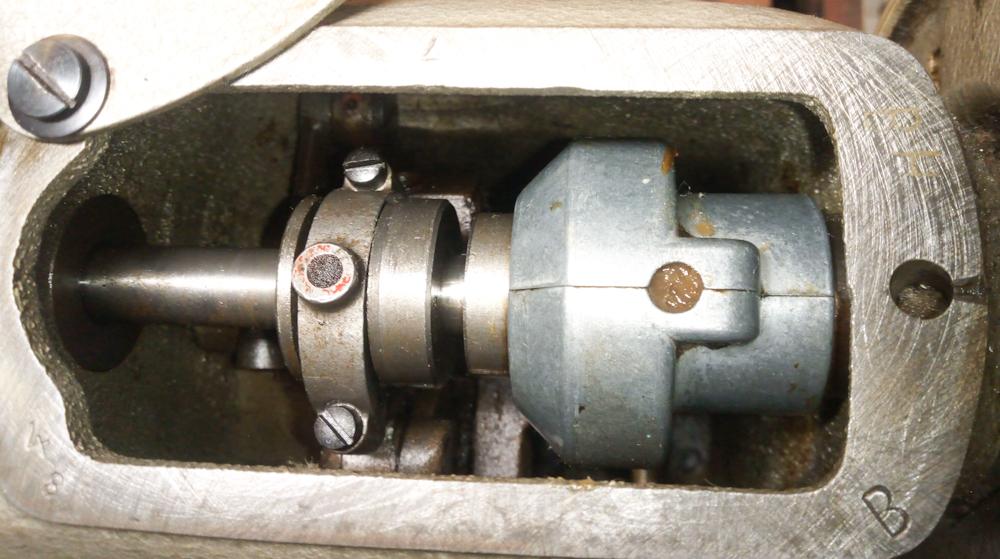

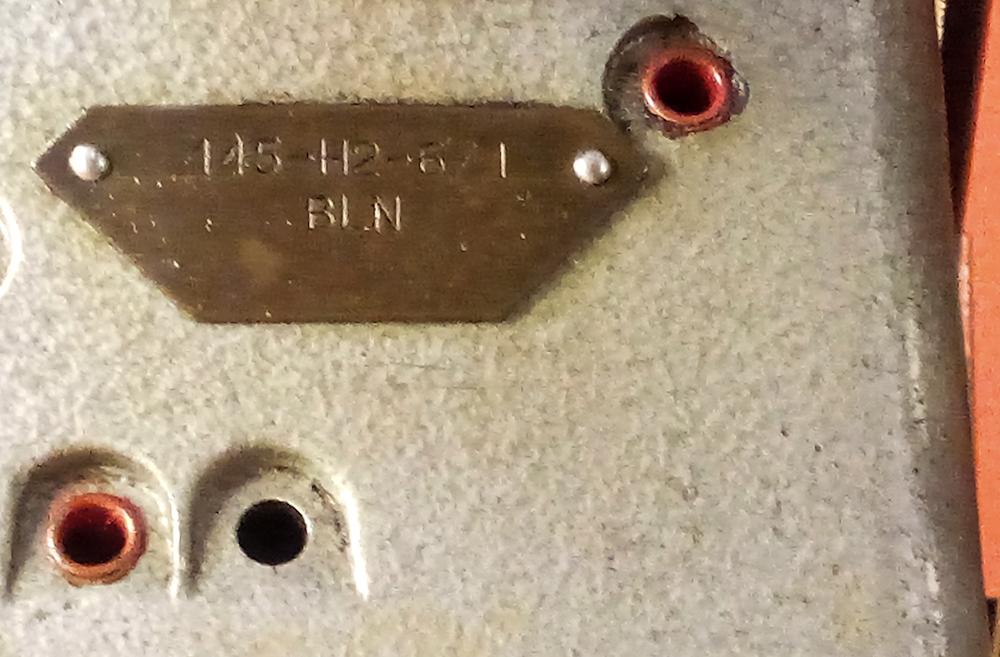

Made some photos. The spring of the stitch adjusting/reversing lever itself seems to be fine. Measured the resistance and it takes a force of 4 Lb to move the lever to the middle position! It is difficult to make a clear photo of the plate it reads 145-H2-6/1 BLN.

-

Thank you Uwe! I will try to follow your advise and ofcourse report back. !

-

Thank you Kgg I had both manuals already but the information for the 145 is limited.

-

-

Hello Everyone I have got a Pfaff 145 H2 for a few days to try out. It has some problems I should like to see if I can fix by myself. The stitch is changing all the time adjusting the bobbin or upper thread tension does not help. Turning by hand gives a little better stitching. Using reverse after a couple of turns the machine blocks. The hook timing seems to be ok. Using the motor it gets worse: The stitch length adjusting lever starts vibrating and the machine blocks. The lever itself behaves strangely sometimes it returns normal from the reversing position and its spring seems to be strong enough other times it sticks. Do you have any suggestions other than ditching it for me? or is there a workshop manual or something similar online for troubleshooting and adjusting? Thank you Jianis