Zeekar

-

Content Count

16 -

Joined

-

Last visited

Posts posted by Zeekar

-

-

I was thinking the outside presser foot presses on the area where the feed dog is and interfers with its motion/doesnt actually exert enough pressure to keep the material in place since the feed dog moves underneath.

@Wizcrafts I havent really found any narrower feed dog/throat plate combinations if I do thats also one option.

-

-

Hi all.

I bought some basic feet for my 1245 from Ebay and the standard foot was a bust. Hole for the set screw was too narrow. Two other feet I bought were L/R zipper feet:

https://www.ebay.com/itm/165955172718

These actually fit on the machine but they are so narrow that the outside foot is actually on the feed dog by a couple 1/10s of a mm. This doesnt seem right. Or am I overcomplicating? Id like to know before I start a reimbursment process and send the feet back to china.

Thnx.

-

Thnx all!

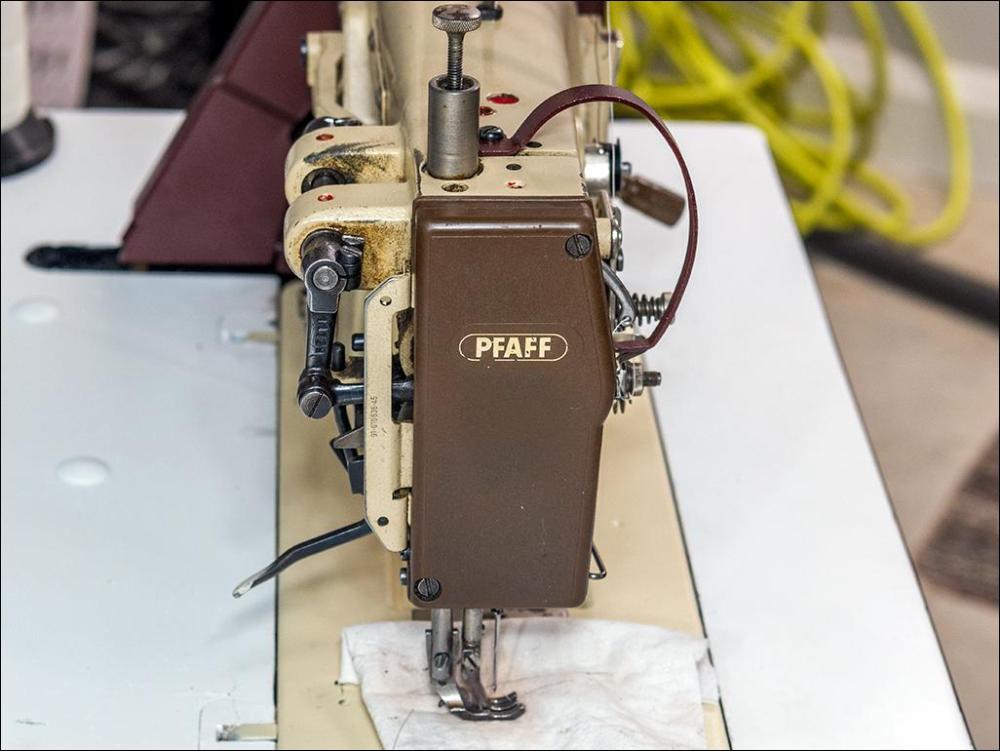

Got it all setup now. The cleaning was pmuch done when i took a can of compressed air and just blew out the lint. No real goo or anything stuck and the machine spins freely and nicely. I oiled it up and did some test stiches. The servo is a bit fast (it came with a 65 mm pulley) so i will eventually replace it. Otherwise its running great!

-

In the end I took the pfaff. Clutch motor. Could feather it quite easily when testing but its really noisy. Carrying the assembly up to the 4th floor was also an edevour.

Machine is also quite clean. Needs good oiling however and maybe cleaning of old gunk. What do people use/recommend for cleaning? isopropyl alcohol? Or cleaning gasoline? I can post pics to see if thats even needed.

-

Yeah the singer was a dead end.

Broken lifter lever so to even thread the machine I had to use the knee lift. Bobbin winder was barely functional and would need replacing. A lot of play in the needle bar and apparently it was setup with a different needle system than the 135×17, the needle was a lot shorter than the ones I bought and brought with me and the hook and needle were out of time completely with my needle. Hook also seemed in bad state and the latch for holding in the bobbin housing was broken so I had to use tweezers to even unlatch it. Motor was also behaving wierdly. Sometimes after turning on it started running the machine without any input. But thats probably solved via pedal linkage adjustment. All in all I dont have the patience and probably the knowledge to fix it at this point of time.

Ill go take a look at the pfaff next when I arrange a meeting with the seller.

I got a quote for the Adler repair. 200€ + part cost. jikes. If I go with that one the repair will be a DIY job.

-

Tnx. Ill take it in consideration.

Just to give something back. I've been researching the adler 167 timing belt change and found this video. At 5 min mark it explains the bearing is glued inside and he loosens it with hot air from the inside. Hope it helps anyone.

-

6 hours ago, CowboyBob said:Yes,you shouldn't have any problems with #14 needles & 46 thread,if you do come back here & we'll help you fix it.LOL!

Tnx for the offer Ill take you up on it if I'll need it

5 hours ago, kgg said:

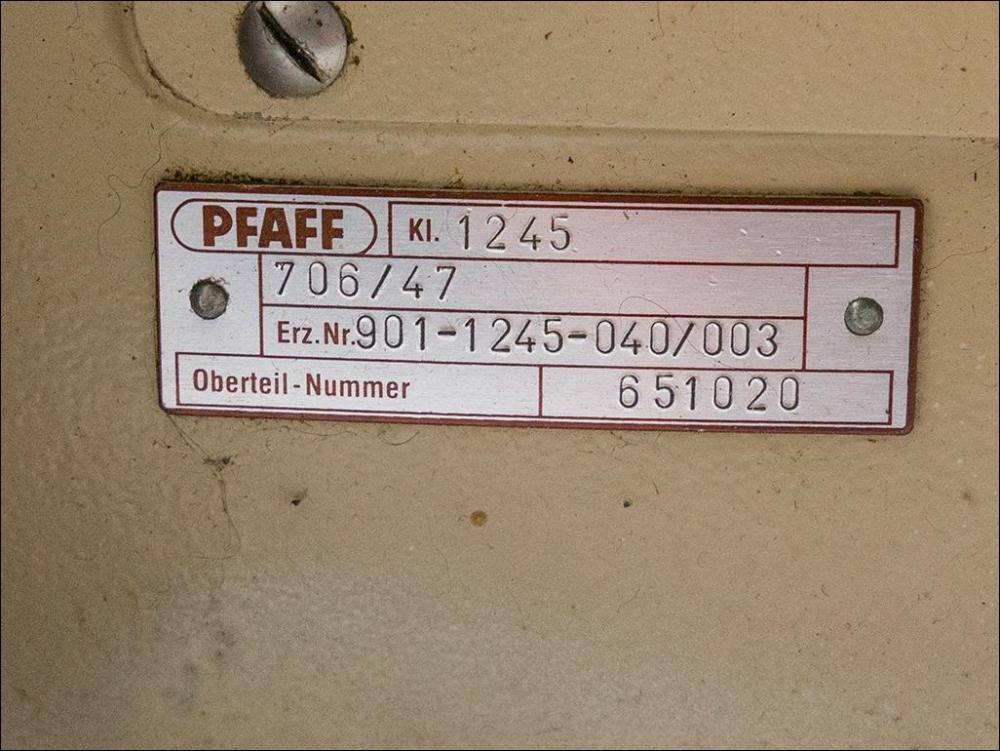

5 hours ago, kgg said:From the info I have see it is rated for system 134-135 needles in the range 110 - 140 ( #18 to # 22). That to me indicates it can handle thread V69 (40) to a max of V138 (20) in thin material. I did own an old casing PFAFF 1245 for a very, very short period of time a couple of years ago and it was a disappointment. Also it did have a small bobbin.

There is a couple photo's of the machine after I overhauled it and it's name plate.

kgg

What dissapointed you about it? Just the small bobbin?

P.S.

Your machine does look nice after the overhaul

-

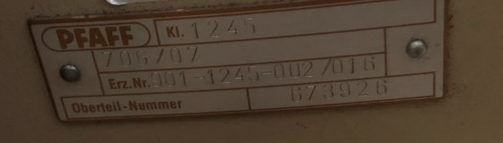

I've recieved the info about the Pfaff and just to be sure I'm not ignoring a good machine Id ask a couple of more questions. Here is the plate:

If I'm reading this correctly the type is 1245 - 706/07. I havent found anything referecing to this exact model except that it uses needle system 134-35. When ever I try to find needle range it mentions models A, B, B/C, C or D with the latter three being 1245 and the first two 245. 1245 seems to be for needle sizes 110-140 or higher.

So what I'm trying to figure out if any one has the experience with this type. Can it be used with needles size 14 (90 metric) and thread 45 (tkt 60) (and up ofcourse) or is it too heavy duty?

-

According to the manual I found online the 666 class has the smaller bobbin. 466/766 are the variants with the larger bobbin.

Im not completley sold on either machine. Im not a great sewist and I like to do things well so I would prefer low speed control. If thats possible with just a servo upgrade on the singer Id be happy and done. I dont think I need the punching power to go trough stacks of veg tan leather (nylon / polyester should be easier to pierce even with the amount of layers im working with).

The adler really suffers from expensive parts. The belt is 50€ shipped and each additional foot is between 30-50€ which also adds up (zipper feet are a must). Still from reviews it seems like a more quality machine which would serve me well if I get it serviced or I service it. I'll call the local mechanic and see what he thinks about the repair.

I did think about buying a new machine but the offers here seem quite poor.

Linked machine is available for 1100€. But I cant find any reviews or experiences regarding that brand or exact machine. Paying that much money for a unproven clone is a bit much in my book.

-

Yeah Im taiking a look at the singer on tuesday and if thats a dud ill go check out the adler. The timing belt change looks like its a bit of a pain but not impossible.

Ill check that the forward and reverse match. The stich length of 5 mm is plenty.

If you have any more advice what to check on the Singer I'm open to advice.

Any case thank you all for all the help. Its very much appreciated

-

6 hours ago, CowboyBob said:The Singer 211 has a smaller handwheel making it harder to slow down than the other 2 & do to the design of it you can't install a larger pulley on it,for this reason & the fact that a few of the screws for it aren't available anymore would steer me towards one of the others.They both have larger bobbins too.The 167 should have a rubber belt in it,if it's cloth don't buy it.

The seller sent me a picture of the inside. The belt looks like it's rubber, but it also looks quite worn. Would this need replacing?

-

17 hours ago, dikman said:As long as it sews/runs ok the Singer would probably be your best bet, in my opinion. They are well built and parts (feet etc) should be cheap. The motor setup on it looks like it may be variable speed rather than a clutch motor, if so you could use a VFD, as Gerry suggests, to run on single phase. Just set the VFD to a fixed speed and use the variable speed in the motor control unit - I think it should work.

Otherwise just buy a servo.

Tnx!

Yes from the additional pics Ive gotten it seems its equiped with an efka variostop. Ive attached the pictures i got.

Could you (or anyone) also give me some advice what should I check on the machine before I purchase it.

17 hours ago, GerryR said:The idea of using the VFD is the clutch motor will no longer be on all the time but will be under control of the VFD via the foot pedal. You just lock the clutch on and when you use the foot pedal the motor will run at the speed based upon the position of the foot pedal.

That makes a lot more sense

-

Thats definitly an option but the main issue I have with clutch motors is the permanent on status and the noise that comes with that.

But thank you for the tig welder foot pedal tip. Was just searching for something similar for a different project and this seems like it will fit the bill.

-

Hi all,

New poster on this forum. Found it referenced a fair bit when researching sewing machines so I decided to ask your collective wisdom for help. Its not exactly leatherworking related but I still hope you will help out.

I'm a hobby sewist. Generally tend to make backpacks, tool holders and other utility trinkets. Materials generally used are nylon/polyester 400D-1000D weights, webbing and foam for padding. Most of the time my domestic sewing machine is limiting when I try to sew trough the foam since the foot clearance is too low or when I pile up the layers (6 layers of nylon (base material + lining) or 2-3 layers of webbing). Not to mention shifting of layers with a bottom feed machine. The other problem is the thread. Tex 50 is currently the maximum I managed to get working with this machine and getting consistent results. The machine already seemed to be strugling with it. I would like to upgrade to bonded nylon 69 or 92 thread. Doubt I will have to go any higher for my application. I would like to also keep an option to do any light leatherworking in the future (backpacks from leather just look cool and Im looking in doing some tool belts for friends).

I'm looking at buying a used machine in the ~ 500€ range. I'm looking at flatbed machines at the moment since cylinder arms are very rare around here and usually way out of my budget. I can handle my way around a machine with a service manual so I'm not too afraid of adjusting a thing or two if needs be.

I have narrowed down my search to 3 machines:

DURKOPP ADLER 167:

It comes with a table a shorther one which is actually a plus since i dont have that much room in my apartment. Also has a single phase servo motor of unknown power. The machine from the looks of facebook pictures looks in decent condition and has been used to produce leather goods recently. I havent had the chance to contact the seller for any further details.

What worries me is the cost of extras example feet and spare parts. Quick googling has shown the parts being quite expensive so any possible repairs would be very expensive even in a diy setting. I've also found that the timing belt change can be a big problem. Its also almost a 2h drive away from where I live otherwise I would have probably already go and check it out.

Second machine is a Singer 211G666:

Currently asking price is 300€. Comes with a 3 phase clutch motor so that would need changing to a servo. Current owner doesnt know any recent history of the machine since he took it as part of compensation. From what I've read its a reliable machine that is relatively ok to mantain and the parts are plentiful. It seems like it would be a good deal if I can haggle down the price a bit. A 500W servo runs for about 180-200€ round here. The location is also on the way to work so its easy for me to go and check it out.

Third option is a Pfaff of unknown type.

The seller will let me know on Monday what is the exact type (it seems like a 1245 but i'm really not sure since I've only saw them trough pictures):

Asking price 250€ and as the singer it also comes with a 3 phase clutch motor. Same caveats apply as with the singer and the additional problem of having expensive parts which arent readily available. But its a Pfaff which is synonim with quality around here.

All three machines seem to be more than up to the task of what I will require of them or did I miss anything obvious? Like any of the machines being too heavy duty to actually be adjust to such low weight thread that I plan on using?

When I go to check them out what should I check on them? This would be my first industrial so I'm kinda lost here. I'm planning on taking some thread and material to try them out but what are the parts that are prone to wearing out on such machines?

I'm personally leaning towards either the Singer or the Adler. Adler because its pretty much a full package and Singer because its cheaper to maintain and get accessories.

Thank you in advance for all your help.

Presser feet - Pfaff

in Leather Sewing Machines

Posted · Report reply

Yes. My worry was that the presser foot wont do its function because its not over the throat plate. I did another batch of stiches and it seems to be working ok for now.