-

Posts

11 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Yoshi888

-

Seems I broke my Juki-LS-341, again... (Bobbin Shuttle)

Yoshi888 replied to Yoshi888's topic in Leather Sewing Machines

Sorry for my late replies, I currently have quite some things to do, so I can only work on the problem from time to time. Thank you @Wizcrafts for the info about terminology that helps a lot to specify problems more accurately. I have done the adjustment again, so the gap between the two parts is as small as possible, but the latch opener still releases the thread somewhat early. It works, but I don't think it is ideal. While I was playing around with the fine-tuning and adjustments, it seems I managed to trigger the safety device that disengages the lower drive shaft. I assume the way it should work is that when a certain force acts on the hook the wheel should slip so it does not break the hook or other parts. I have checked the Engineering Manual, and from what I can gather after repositioning the lower shaft, it should engage again. But it seems to slip off very easily and thereby does not turn the lower axis properly. Is there another step I am missing to engage the safety mechanism again properly? Once again, I have attached a video to better illustrate the issue. Thank you all for the help. I am getting better and better at solving those things 😇 PXL_20251117_155311108 (1).mp4 -

Seems I broke my Juki-LS-341, again... (Bobbin Shuttle)

Yoshi888 replied to Yoshi888's topic in Leather Sewing Machines

Also not sure it is completely the right term but it's whats referenced in the manual. It is the part on the bottom left of the video that holds back the thread after the hook released it across the bobbin. To my understanding it should be kept there a bit longer so it does not get entangled with the bobbin mechanism. But currently it basically releases the thread instantly after it passes above the bobbin case. -

Seems I broke my Juki-LS-341, again... (Bobbin Shuttle)

Yoshi888 replied to Yoshi888's topic in Leather Sewing Machines

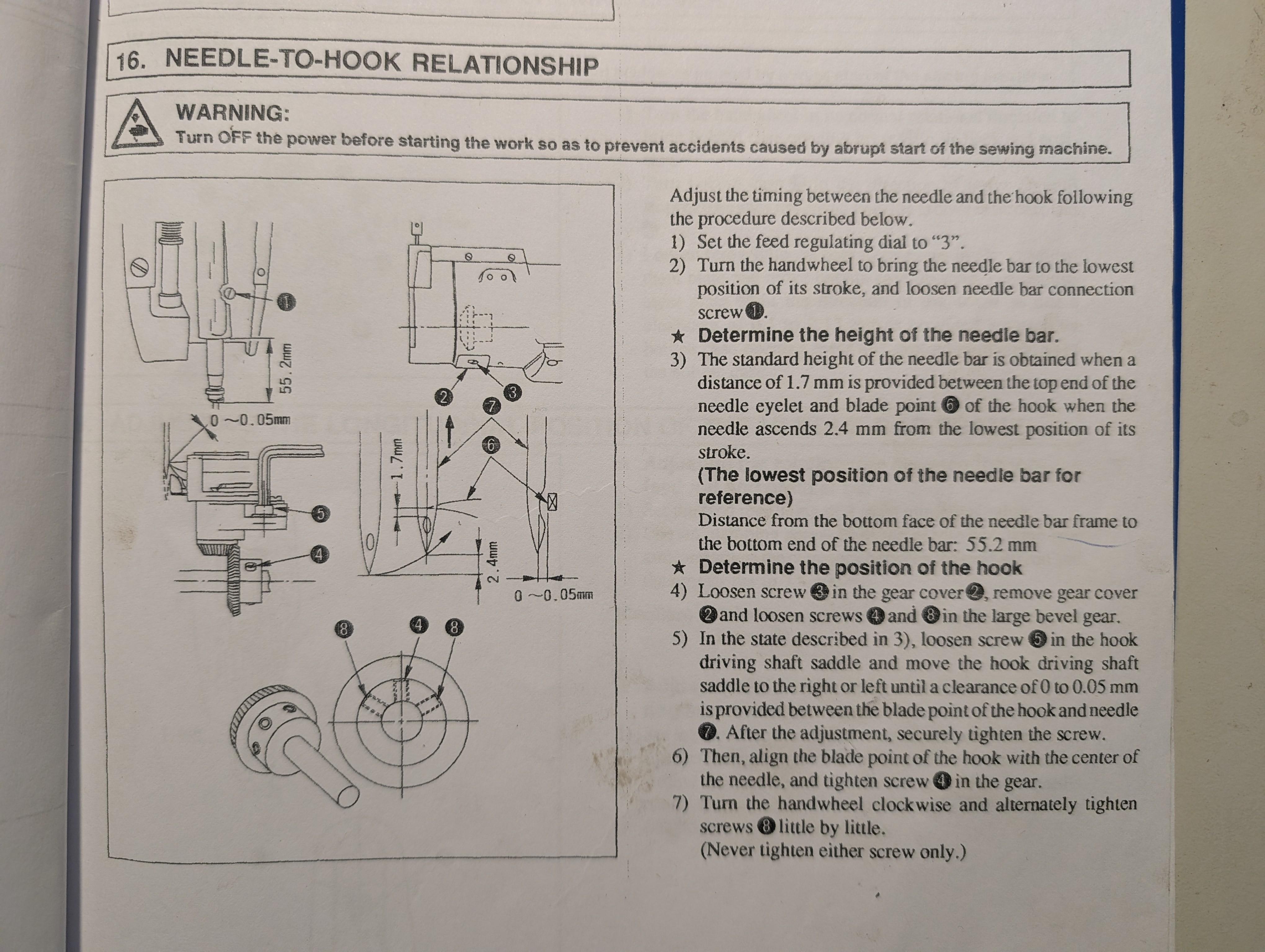

I have now managed to do the needle-hook timing. While the gear on the horizontal shaft was indeed very stuck, what worked for me was to insert the hex key and turn the shaft, and with enough leverage, I was able to turn the gear on the shaft to adjust the needle-hook timing. Additionally, I saw that I also had to adjust the position of the tip of the hook as it was hitting the needle slightly. This is where I made one mistake as I first loosened the screw for the Inner Hook Guide instead of the hook driving shaft saddle. So after I finished the Hook-Needle Timing, I wanted to adjust the position of the Inner Hook Guide again , but no matter how close I set it, it releases the bottom thread way too early (I once again attached another video) So did I do something wrong with the hook-needle timing? I had to adjust it further than I would have originally thought. So, did I maybe miss something in regards to the stitch cycle in which the parts work together? I tried to look at some other resources, but could not spot an issue or difference. I really tried all options with the possible positioning of the Inner Hook Guide, so I don't think it could be just that. So once again, I hope you have some ideas or help. But I really think this should be the last step. At least after this whole ordeal, I feel much more confident regarding any issues my sewing machine might throw at me in the future 😂 PXL_20251030_164552655 (1).mp4 Kind Regards Josh -

Seems I broke my Juki-LS-341, again... (Bobbin Shuttle)

Yoshi888 replied to Yoshi888's topic in Leather Sewing Machines

Thank you very much @friquant for the videos. They were very helpful. I had been wondering how I get these measurements right and the tips from the video were extremely useful! I have also found the needed measurements from mine in the Manual. But alas it seems theres one problem left. I have prepared everything and removed the screws (4,8) as instructed. But the gear on the horizontal shaft does not move or rotate an inch. I understood from the manual that after loosening the screws I could retract it to disengage with the wheel on the vertical shaft, allowing me to adjust the hook in the proper position before engaging and fixing the gear in place again. But I absolutely can't get it to move and didn't want to use more force in case I misunderstood how this steps works. Did I misunderstand the process or is the gear just very stuck? Kind regards Josh 😇 -

Seems I broke my Juki-LS-341, again... (Bobbin Shuttle)

Yoshi888 replied to Yoshi888's topic in Leather Sewing Machines

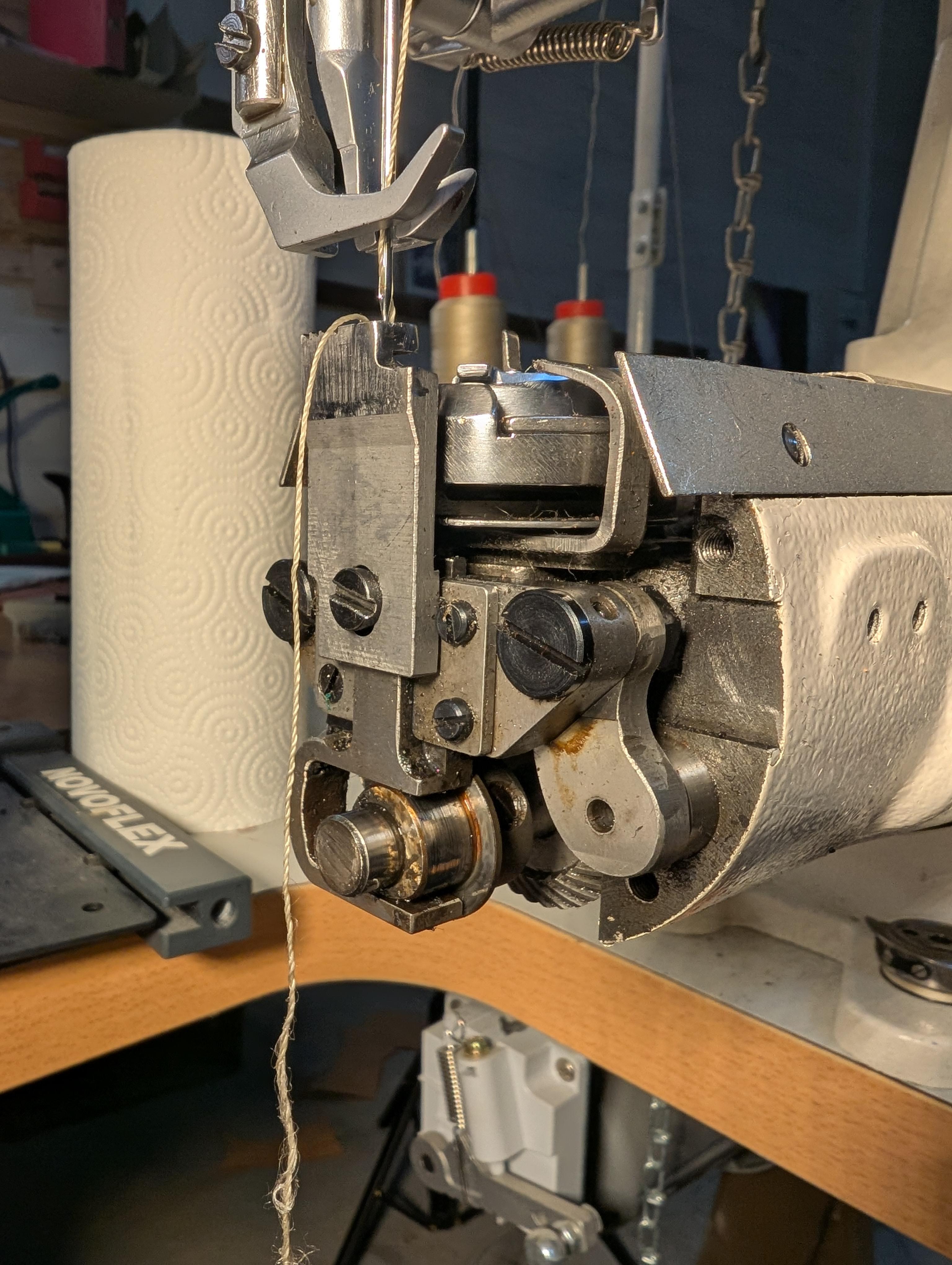

Finally had some time to properly check and fix everything. I first readjusted the gear on the horizontal axis, but that did not seem to make too much of a difference. Next, I checked where the play on the horizontal axis came from. So I removed the Belt cover and opened everything up. I found that the bushing that keeps the axis in place (as shown in the screenshot) had come loose. Resetting that part removed all the play in the axis and also stopped my machine from locking up! So it seems I have found the culprit and fixed it! The only remaining problem seems to be that while doing all that, I have changed my needle timing after all... As seen in the video below. It seems in the end I will also have to learn how to adjust the needle timing. At least once I learned that as well, I am confident I probably will not need a mechanic for my machine anytime in the near future, which is good as the next one is more than 200 km 😂 @AlZilla @friquantThank you so much for the help, I appreciate it a lot. Do you also have any tips or resources for setting the needle timing :)? Kind Regards Josh PXL_20251022_210024307 (1).mp4 -

Seems I broke my Juki-LS-341, again... (Bobbin Shuttle)

Yoshi888 replied to Yoshi888's topic in Leather Sewing Machines

I was a bit to curious to wait so I just went over to the workshop to take a look. It seems the horizontal shaft has some play. I screwed in the center screw of the bobbin to pull up the vertical shaft and tested the two cases. When I pull it outwards (to the left) it does not bind up. When I push it in (to the right) it binds up at a fixed position. So my best thought at the moment is also what @friquant suggested. Once I collect my nerves this week, I'll try to reset the horizontal shaft and fix it in place again. Hopefully, if I watch out for the correct position, I can also save my hook/needle timing. But that already gives me hope I don't have to order spare parts again. That was quite an ordeal last time. @AlZilla If the above doesn't fix it that will then be my next task. I think the Belt connects only to the top, so I assume it uses gears but I'll double check below the cover next time because that would probably also be a good thing to know about my machine. Here is also a video again that shows it a bit better than I can explain. PXL_20251013_185331839 (1).mp4 -

Seems I broke my Juki-LS-341, again... (Bobbin Shuttle)

Yoshi888 replied to Yoshi888's topic in Leather Sewing Machines

Thank you so much for the advice I took a look at the gears, and there are no teeth missing. It appears that the vertical driving shaft has some play, but I think that might be because it is fixed to the center screen on the Bobbin Carriage (Sorry, I sometimes don't know the proper part names yet.) I cleaned any dirt on the bevel gears, but that did not change anything. I'll take another closer look tomorrow, but if I cannot find anything else, I will probably start removing the other parts to take a closer look at the vertical shaft. Is it possible to disassemble it further without ruining the needle/hook timing? -

Hey everyone, I love my Juki-341N, but it seems I once again managed to damage my poor machine. I was sewing as usual, but suddenly it bunched up. I removed my work piece and the thread, but also with the handwheel, it was not properly turning anymore. So I started disassembling it to see if there was some thread stuck near the bobbin, but there wasn't anything. Then I removed the whole shuttle to see if there was anything wrong. I have attached a video here, and it seems the bushing inside the brass/copper ring gets stuck when I turn the handwheel too fast. I have cleaned everything I can, and I cannot find anything stuck anywhere. If I slightly push on the Bushing, it seems to work better, but also after cleaning and reattaching the bobbin, it gets stuck very easily. I did not want to disassemble it more because I am not too knowledgeable about this, and I am worried about ruining the alignment/timing. Do you have any idea what could have happened here and how I could fix it? In case it is relevant, I changed the shuttle a few months ago, but there have not been any problems since then. PXL_20251010_182024859 (1).mp4

-

While I am usually more active on Reddit, I want to become more active here as well so I thought I would also post a bit of an Intro! Leatherworking has been a passion for many years and roughly 18 months ago I also started my own Business. I am from Germany, and luckily, we still have a very big Craft Fair culture (Kunsthandwerkermärkte) and I make most of my money there. I also sell online, but most of my business is in person. This year I also started my own Youtube Channel and make videos for the Patterns I publish. I love designing and making new products so creating and selling patterns was a perfect excuse to always come up with new product ideas. And next year, I will finally open my own store as well 😇 I have a lot of renovation to do over the Winter, but I feel so blessed and excited that I have the opportunity to have my own store. Here is also a Market of me at one of my Craft Fairs some months ago. Happy to be here and be more active in the Future Happy Crafting Josh

-

Replacing the Hook (and Bobbin Shuttle) on a Juki LS-341N

Yoshi888 replied to Yoshi888's topic in Leather Sewing Machines

Hey I am so sorry, I thought I had my Notifications on, but did not, and totally missed the responses Thank you so much for the Input! I did end up making the repair myself, and it worked great. So also for confirmation in case someone else sees the post in the future, the steps and video worked perfectly for my Juki-LS341 and I did not even have to any realignment or change the needle timing.- 5 replies

-

- sewing machine repari

- juki ls1341

-

(and 2 more)

Tagged with:

-

Hello everyone, I bought a used Juki LS-341N for my Leather working Business 1-2 years ago, and it has been a great machine so far. Recently, I made a mistake when sewing thicker material, and it seems I have broken the tip of the Hook next to the Bobbin, so the hook does not properly catch the upper thread anymore. I have tried to resharpen and reposition it so it can catch the thread again, but to no avail. When I position the hole sled with the bobbin closer to the needle, the needle hits the side of the bobbin and is bent away from the hook. So it seems the Hook is too damaged that it could be fixed with sanding and readjusting. Luckily, the original seller sold me a new sled (the hole bobbin shuttle with the Hook). Now I have contacted a mechanic who would be able to do the replacement and service, but they have not been very responsive. (I am located in the Southwest of Germany and have not found other options except this person) So I am trying to evaluate how hard it would be to do this myself. Changing the part does not seem too difficult, but adjusting the needle hook timing and the exact hook position has very small tolerances, and I am not sure how well this can be done by an "amateur". Do you guys have experience with this, or could you give me an estimation of the difficulties and pitfalls of such a task? Any help and input would be greatly appreciated! Cheers Josh

- 5 replies

-

- sewing machine repari

- juki ls1341

-

(and 2 more)

Tagged with: