Search the Community

Showing results for tags '1508'.

-

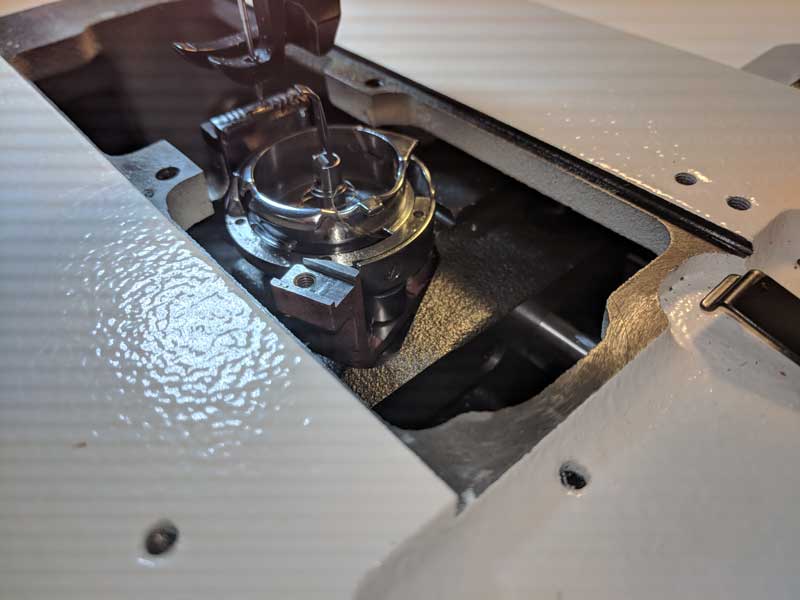

Hello there Ladies and Gentlemen, I'm hoping one or more of you marvelous sewing machine magicians would be so kind to lend me some advice on this problem that has me at my wits end. Background: I have been sewing nylon webbing using bonded nylon thread, everything has been working fantastically for quite some time until a few days ago. I had a needle break and the machine got jammed, I cleared the jam and got everything going again not thinking much of it. Next time I was back on the machine I noticed skipped stitches and needle thread being cut on occasion. To resolve this, I checked the timing and noticed the hook rotation was retarded according to the factory manual. I went ahead and corrected the hook rotation, made a small tweak to the needle guard, and generally got everything in-line with the factory specs (rotation, hook tip to needle distance, needle guard deflection amount.) I'm not sure if the rotation got knocked out of spec from the jam or if that's how it came set up from the dealer (had them set the machine up after purchase a few years ago.) Testing out the machine after the timing change seems to have resolved the previously mentioned issues, however while testing I have now noticed another problem... Problem: The bobbin thread is pulling up to top of material on corner stitches. When sewing a straight line of stitches the tension balance is fine, however when turning the corner stich knot pulls up like the upper tension is too much - resulting in the upper thread slightly cutting across to the next stitch. I stop and turn when the needle has started to rise and the hook has captured the upper thread. I have never had this problem before, sewing the exact same material, same thread, same needle. It leads me to believe something may have gotten knocked out of spec? I can sew straight for inches and inches with the tension remaining consistent, but as soon as I make a corner stitch the bobbin thread comes to the top. Here's what I have tried, all without luck: Retarding the timing back to where it was before I set it to factory specs Reducing upper thread tension (It lessens the effect of the problem, but the problem still exists and then the balance of tension on the straight stitches is off.) Using more and less bobbin tension with compensated upper tension Turning the material at various different points during the needle stroke New needle Smaller needle It doesn't consistently do this on every corner, I would say 50% of the time when turning material clockwise and 40% of the time when turning the material counter-clockwise. I can't wrap my head around what may be causing the tension balance to shift to the upper side when turning the material? Do any of you gurus have any insight you can lend me? What else can I check? Thank you in advance for taking the time to read this!!

-

Hi all, I have a Juki 1508 (1508NH specifically) that I am now experimenting with for production wallet sewing. This machine, along with my others, have primarily been used for canvas work and I'm very inexperienced with leather sewing. I pulled out some leather scraps yesterday and now understand it's going to be quite a bit of fiddling to get a nice finish! I was hoping I could get some advice on some immediate issues - I have no access to a machine mechanic because of where I live unfortunately, however this machine will be dedicated to this one task, so it can be tweaked for its purpose. The presser foot & feed dog are leaving tracks along my leather. Can the presser foot be replaced with something made of nylon? Are there special 'leather feed dogs' which have less aggressive teeth, or is it all about tension and adjustment? I'd like to use M20 nylon bonded thread - what is a leather point needle recommendation for this thread size? I need to slow the machine right down (clutch motor) - is a smaller pulley the way to go or must I get one of the more specific speed reducing pulleys which also gear the machine for torque? The Nick-O Sew dual speed reducers on eBay are nice, but after USD conversion and shipping to Australia it's an expensive bit of gear. Thanks so much! -m

-

does anyone know how the quality is on the econosew machines im looking at a1508nh whitch is the same as the juki 1508nh , just looking at some input, i will save about 1000,00 on this setup i have a cowboy 4500, and im looking to get a flat bed that can do liter work.. thanks nelson