Search the Community

Showing results for tags 'feed dogs'.

-

I recently acquired an Adler 169-373 cylinder arm machine. It had many issues ( you get what you pay for, right?!). I have taken care of most of them, however, the one I cannot figure out is, the feed timing issue. The needle and inside foot as well as lower feed dog all start moving back ( toward operator) before the needle has cleared the work. This is completely wrong for a compound feed machine. I have never had this issue and don't know what to adjust. No manual I have found has dealt with this adjustment. Any help out there? Current collection of machines- Adler169-373, Adler 67GK373 (2), Adler 205-64, Consew 225, Consew 225RB-3,Singer 153W103, Singer286G132, Singer111W154, Singer 29K60, Adler 30-70, USMC Model C clicker, Randall NSB Edge Beveler.

- 8 replies

-

- timing

- adler169-373

-

(and 1 more)

Tagged with:

-

Good Evening, I recently purchased a Singer 111W155 for $225 . The seller had inherited it. The seller plugged it in and pressed the foot pedal. The needle went up and down without cloth and thread. Motor and machine sounded ok. After getting it home, I sanded the top, re-stained and put a poly coat on it. I cleaned the fuzz and wiped it down. I plugged it in and put a piece of thick cloth in it and pressed the pedal. The needle danced up and down, but the cloth did not feed. I researched and found some videos and refurbish sites. I also found this site and have been searching and reviewing. This topic was helpful: As I went through this topic, I read Eric's post and Uwe's post and video. I then decided to check out the upper and lower shaft timing. It was off. I corrected it. The cloth then fed. Also the handwheel was not tight. It had only one screw with flat end in the grove position. I purchased the correct screw and made sure they were in the correct positions. The position of the stitch length indicator was off. I turned it toward the lowest position until it stopped. I loosened the set screw and rotated the indicator until the bottom of the number 32 was centered in the hole. I re-tightened the set screw. I turned the handwheel until the maximum stitch length position was achieved. The top of the number 32 was centered in the hole. I haven't found a description on how to do this. I downloaded http://militarynewbie.com/wp-content/uploads/2013/11/NAVEDTRA-14217-Aircrew-Survival-Equipmentman-1-C.pdf using tjas's link. I used the print to pdf function to print only chapter 4 to a pdf file. Then printed it off. I also downloaded the TM10-3530-202-24 as well but haven't got to it yet. After reading Eric's comments I decided to go through Chapter 4 in order. The feed dogs were set to maximum height. I tried to correct this. I found that if I set the valley between the teeth level with the top of the throat plate using the front half of the dogs then the rear half of the dogs are a little too high. Is this good? or am I splitting hair here? Many thanks to all the contributors and support vendors.

-

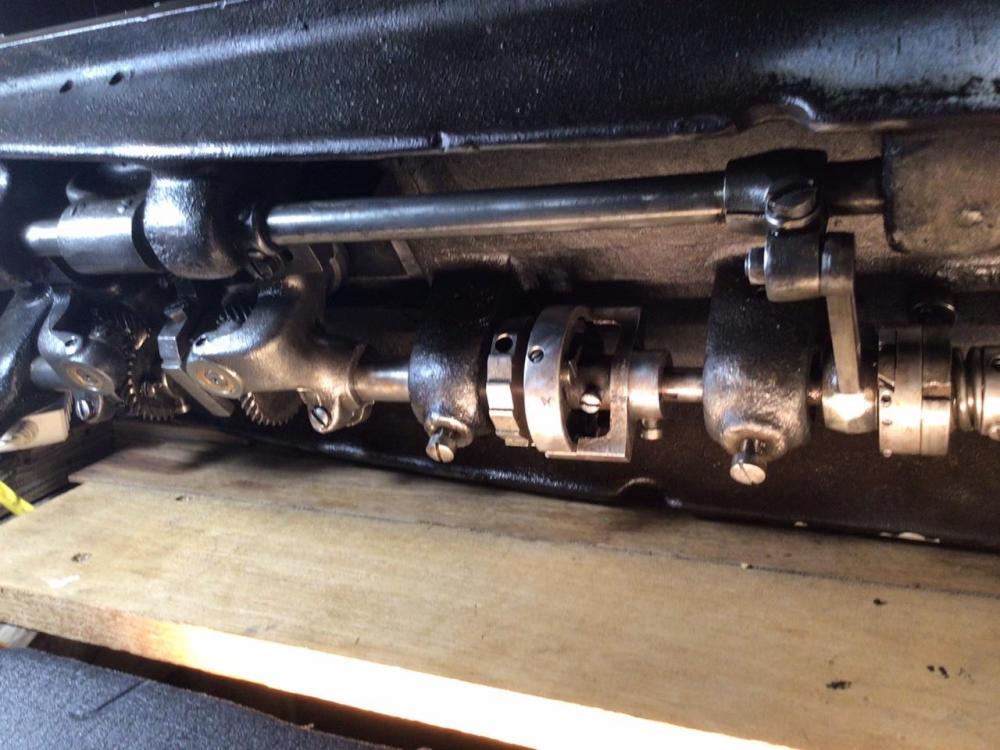

My 145w204 had been sitting since the 70’s when I purchased it a couple weeks ago. It had no rust, but was covered in decades of warehouse storage, spiders, and varnished oil. Machine wasn’t seized, but very close to it. Mainly old oil that had turned to glue. Got it tore down and polished everything clean and smooth. Stitched like a champ. Belt came in and I swapped out the old dry rotted one. Still worked, but not for long. So I put the new belt on exactly like the manual calls for, and I’ve done it 50 more times to be sure. Long story short, everything looks perfect, hooks to needle, runs smooth and quiet, my problem, the feed dogs will not keep time with the needle. At zero feed yes, they line up, start adding stitch length and forget about. Almost seems like something is 180 degrees off. I did not disassemble anything on the eccentrics, just clean and oil. I did check for loose bolts but all was good. So that’s the the gig, my feed dogs and needles won’t time, but everything else looks good. Any advice, hints, or means to a solution would be greatly appreciated. Thanks.

- 2 replies

-

- feed dogs

- timing adjustment

-

(and 2 more)

Tagged with:

-

Looking at many industrial sewing parts I can see they are all made from the same casting with minor differences in machined surfaces. For example, feed dogs may have the holes drilled in a slightly different location or the feeding surfaces may be wider or shorter for different tasks/machines. I bought a Consew 146RB and there are some tasks it just doesn't handle well. Rather than machining complete parts for it out of billet, does anyone have a source for raw castings? I'd love to just machine a few feed dogs, feet and maybe laser cut some plates to match so I can just sew up 100 of the parts I need and then reconfigure the machine to do something different. Michael

- 16 replies

-

- feed dogs

- walking foot

-

(and 2 more)

Tagged with:

-

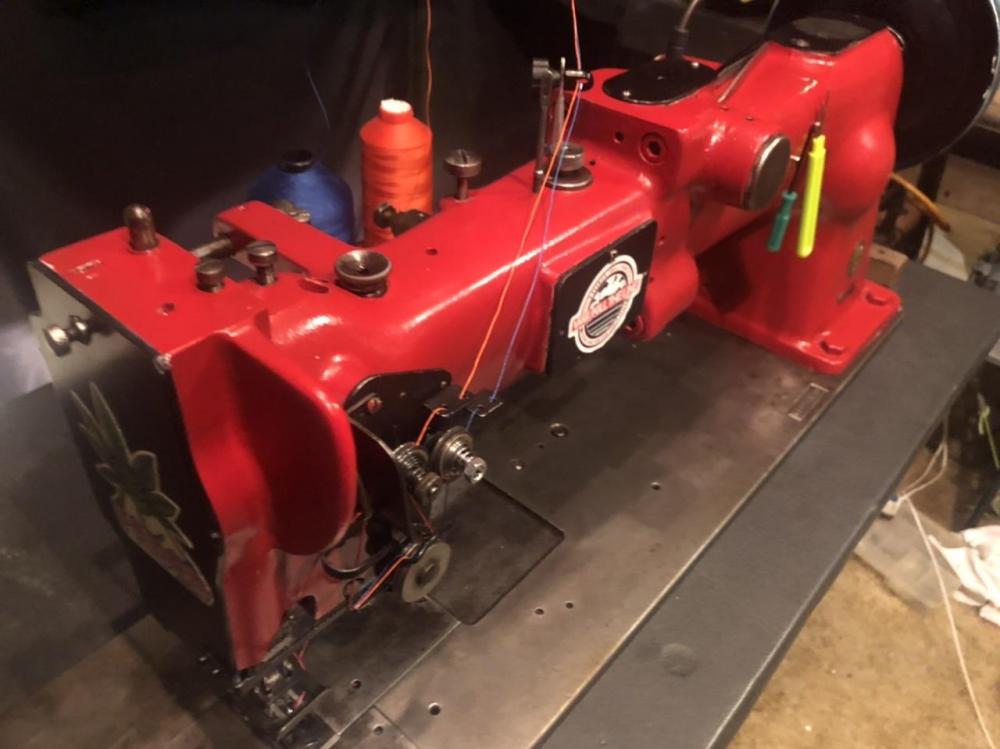

Hi! So I've been working on a relatively newer Pfaff 335 machine and it's been getting the job done. After sewing an entire colonial style jacket out of leather and suede on a commercial machine, I finally upgraded; however, I'm beginning to think I'm making life harder than it needs to be by not using the correct settings for each job. I generally use a 17/105 or 18/110 diamond point needle for most things and the forum recently helped enlighten me about materials / needle / thread combos with the charts I found. I use a flat plate and the feed dogs in the pic below. I work on wallets, duffle bags, jackets, dopp kits and a lot of random luxury items. I even make soft leather holsters. After scouring the site and the manuals, I'm having a hard time finding good resources for what tools do what with my machine i.e. If I'm making a nice, burberry or cole haan type wallet with (fill in the blank type leather) (fill in the blank weight), I'd love to find some sort of 'standard practices' guide that answers: what needle and thread would I use? if binding edges, how to operate the edge binder and how to choose the size feeder etc etc what type of leathers are --typically-- used and what range of leather thickness? if skivving, how thin? when stitching zippers, which feet to use for the machine? I realize this just gets honed with time and each project is unique depending on the tastes but there has to be a guideline? I've figured out a lot thus far but it takes forever. Any help, resources, tables and/or charts are immensely appreciated! Thanks in advance!

-

- industrial machine

- feed dogs

-

(and 4 more)

Tagged with:

-

Hi everyone, (sorry if you're seeing this for a second time!) I'm having some trouble with my right-angle edge binder, which I'm using with my Juki DNU-1541. I've been trying to sew 2oz binding leather onto 4 or 5 oz leather, and it periodically fails to catch the binding leather on the back side (it's wrapping more around the front than the back). I was unable to put in the feed dog that came with the binder set- I can't get the original feed dog unscrewed.. I had assumed it wouldn't make a big difference because the feed dogs look very similar, but could this explain my problem? Or perhaps the mouth of the binder isn't wide enough? I am using the binder needle plate and a knurled binder foot set. I'd love some tips on how to fix this! Thanks!

- 2 replies

-

- right angle binder

- juki dnu-1541

- (and 4 more)