Search the Community

Showing results for tags 'pfaff 1245'.

-

Hi all! I've got myself a Pfaff 1245-706 machine, and thanks to reading other posts on this forum I've been able to (mostly) get it cleaned up and running. When I say mostly running I mean everything seems like it's mechanically smooth, oiled and greased properly, I've spent a lot of time making sure I'm threading it properly and testing out thread and needle sizes to get the right fit. I've finished making a tote bag which mostly went fine, when I say it's running I mean that with enough fussing I've had it making nice stitches for long enough to finish a project. The problem I'm having now (and a bit when I did my first project) is that it seems like it's incredibly easy to throw the timing off. To the point where I can't really re-attach the drip tray under the table or cover the gears that spin the hook race because I need to access and adjust them so often. I'm following the steps outlined in this video starting around 16:36. So I'm getting the needle to the lower dead point, loosening the two screws on the small gear, and adjusting so the hook meets the middle of the scarf when the needle in about 3mm up. And this works... Kind of. Like I said before, I was able to the machine working nicely long enough to finish a tote bag, but basically any little hiccup - tension slightly being off, bobbin winding being a bit too loose, etc. results in the timing being thrown off. Sometimes if there's a big thread tangle I'll have to reset the safety clutch, but often I'll have to adjust the timing without the safety clutch needing to be reset. I can't quite figure out how this happens, as I'm re-tightening the screws on the small gear after re-timing. One guess I have is that this is a tension issue. The thread is usually quite hard to pull through the machine when it's threaded. When I had it working properly the tension dial was set very low and that was producing good stitches, but it seems suspicious. That thread wasn't particularly heavy (it's unlabeled so I'm not sure of it's size) I was sewing with a system 190 size 130 needle which was a good size to have the thread pass through the needle easily. I'm experienced enough with sewing that I think I can match a thread and needle size pretty well. I'm currently trying to set it up to use a heavier thread, labeled as Cansew CBB138 nylon. I'm using a 160 size needle and that seems about right, but again just pulling it through the machine when it's threaded and the foot is up/tension discs loosened, it's in there quite firmly. I wonder if I should be adjusting the way I'm threading, like maybe just going through a single loop on the top finger instead of winding it around a few times like they recommend in the manual? This is my first time working with an upholstery machine and thread this heavy, so I'm not quite sure if it's normal to adjust the threading path if tension is too high, or even if the settings should have to be so precise to avoid jams and skipped stitches. Every other machine I've used from domestics to an industrial Pfaff 563 was a lot more forgiving when it came to threading and tension, very rarely had thread breaking or skipped stitches so I'm curious to hear thoughts on what might be happening with this 1245 machine. As of right now with this heavier thread, it's not really jamming or breaking thread, but after the first few stitches the timing seems off and stitches are no longer being made properly. I can provide pictures if that helps at all, thanks in advance!

- 14 replies

-

- timing adjustment

- troubleshooting

-

(and 1 more)

Tagged with:

-

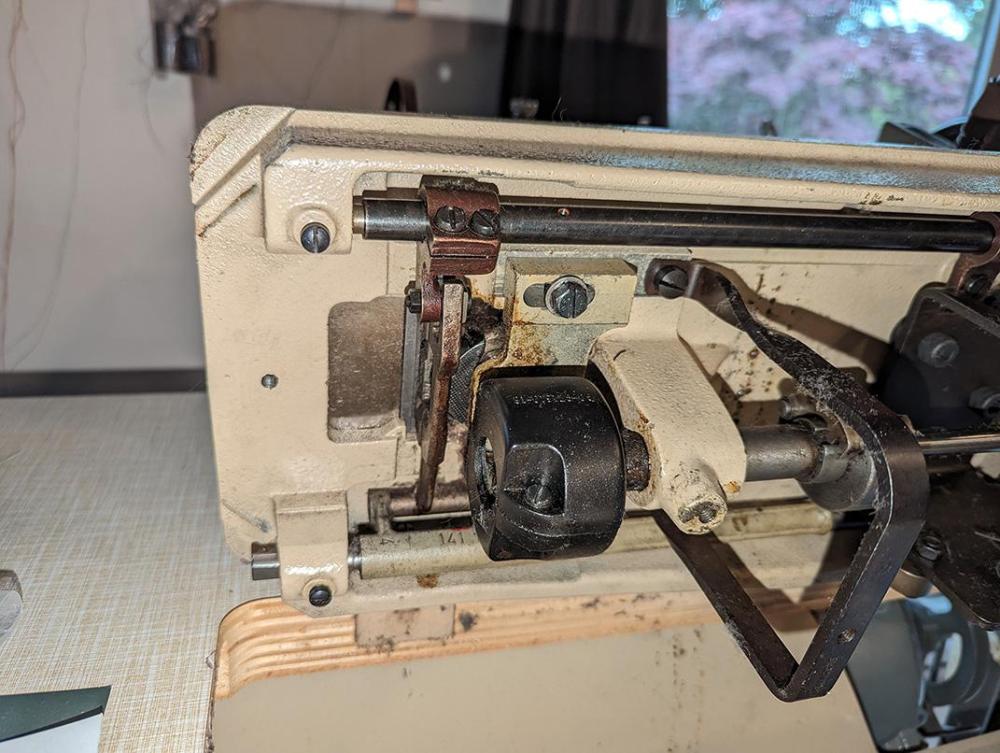

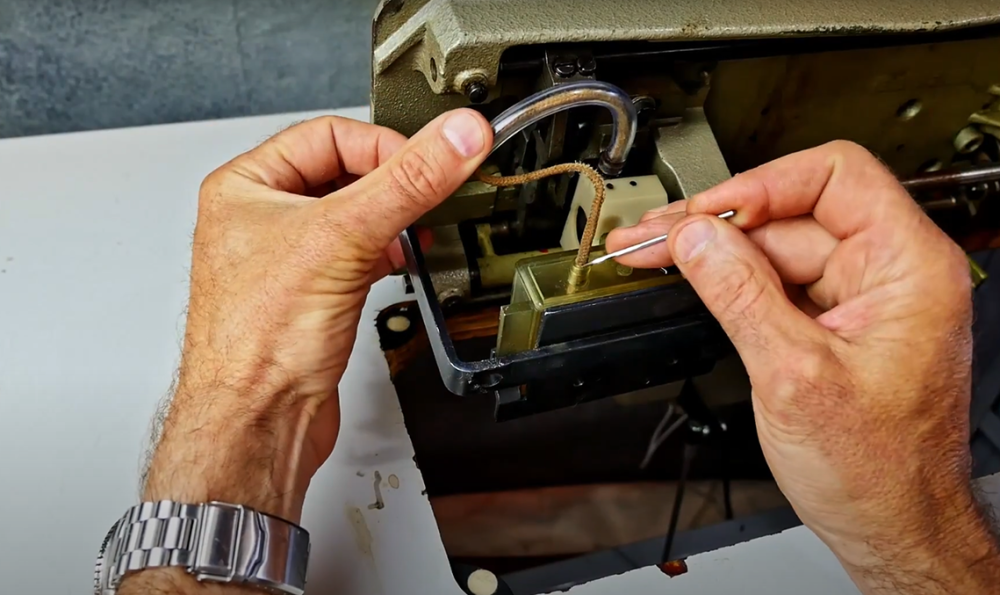

Hi everyone! I've recently acquired an older model Pfaff 1245 and I have a parts/maintenance question that I haven't seen discussed anywhere else yet. A bit of context, this machine was on it's way to the dump and I rescued it - it was abandoned in the alterations department of a clothing store that had gone bankrupt and I was able to take it when the space was being cleared out. As far as I can tell it was being used up until the store closed about two years ago. There were other machines in there which were missing parts or needed fixing but they were labelled pretty clearly so that makes me think this machine is in good shape. The balance wheel turns very smoothly, outside of some oiling and greasing I think it should be ready to use except for one issue: It seems to be missing the oil reservoir that I can see in a youtube video walking through the cleaning of this machine (I'll also attach a screenshot). I also have a pdf manual I've downloaded which isn't very clear, it shows the same oil reservoir (which is supposed to be for hook lubrication, I believe) but also mentions you can oil the hook via a hole in the bobbin area. I'll attach a photo of the underside of my machine as well. It looks very similar to the one in the video, just no oil reservoir and slightly different plastic coverings for some gears. So I suppose my question is - do I need to find an oil reservoir for this machine? It seems like an obvious yes, but there's also evidence that it was being used without that part, and a manual that suggests an alternate way to oil the hook system. Is it possible the reservoir is an optional part to make oiling easier? Seems weird that they would make a machine that way but I've only used domestic machines up until now so I wouldn't know. Or maybe there's a sub-model of this machine that doesn't have the oil reservoir, and mine is meant to be oiled manually? I'm a little confused, would appreciate any insights. Thanks in advance, this forum has already answered a ton of my questions just by reading older posts, I appreciate the expertise!

- 4 replies

-

- maintenance

- pfaff 1245

-

(and 1 more)

Tagged with:

-

Hey guys, I've been using this site for a while for information on industrial sewing machines, especially how to set up an Adler 69 for binding, which was really helpful. Decided to join and ask for help regarding a problem with a Pfaff 1245. Problem: Randomly, the upper thread forms a loop when sewing nylon webbing (2+ layers). Issue is more visible with 6mm stitch length, but occurs at any length, I usually sew at 3 to 4 mm. Bobbin thread looks fine. See linked videos for details on the issue. I managed to get a high speed capture of the problem occurring, and it seems that after making the stitch, the needle comes out, then the threads coming out of the hole in the fabric sticks with the existing upper thread from the previous stitch and pulls it out, then it never gets set back down properly. When it’s less dramatic, the stitch feels weak. I’ve tried many combinations of lower thread/upper thread tension, more tension makes the issue less frequent, but at some point the bobbin thread pops up and the issue still occurs. For comparison, the same needle, fabric and thread combination on an Adler 69 has no problem sewing this fabric in the same fashion. The thread never pulls up the previous stitch and they are very strong. - I re-timed the machine according to the manual, then checked it over multiple times, adjusted feet motion, needle position, hook timing, take up string and so on. Manual says 2mm after BDC, tried 1.8 and 3mm, but no change. - I’ve tried modifying the tension on the take up spring, changed the tension disc, and bought new thread, but the problem still occurs. - Tried a much larger needle with no success. I’ve seen a similar issue discussed here: https://leatherworker.net/forum/topic/67986-random-loose-top-thread-consew-289rb-1/ But with no solution, it’s unclear what fixed the problem. I did try lubricating the thread by spraying it with silicone lube, but it had no impact on the problem. I’ve reached a point where I’m considering selling it and getting another machine because it doesn’t produce quality stitches. It's a bummer because I bought it used and it seemed in good condition. Do you guys have any idea what could cause this problem?

-

I've just acquired a pfaff 1245 subclass 02/011. Anybody have a location for a manual and what this subclass means? Plus any more knowledge you should happen to want share with me about this machine would be appreciated.

-

A local shop has a reconditioned PFAFF 1246 twin needle 9.6mm gauge sewing machine. Is it possible to use as a single needle?

-

I am new to using a sewing machine, I make leather holsters and have been doing them by hand. Due to arthritis problems I bought a PFAFF 1245 color is white, I have tried to use #207 on top and #138 or #92 on the bobbin, my problem is no matter what thread I use on top it keeps breaking or bunching up at the needle. The machine has a servo motor so I am going very slow, when it is not breaking the thread the stitch is very good the timing seems fine. I sew 7-8 oz. leather veg/tanned. When I go in reverse the top thread breaks right away. If any one could give me some advise it would greatly appreciated.

-

Hello all, Many thanks to member and mentor Uwe Grosse for telling me about this awesome web community! I love my new/old Pfaff 1245 706/47 (see photos). Cosmetically, it looks like a low-hour machine. I see no evidence that it was ever repainted. When I got the machine, the heavy-steel knee lifter bracket was bent slightly and not installed, so I straightened and re-installed it, and it works fine now. This made me think the machine may have been dropped at one time, although I see no other evidence of damage on the machine. The table looks like a newer one, so I think it has been replaced (clutch motor works fine). The oil drip pan and collection bottle were missing, so I have ordered those. The machine came with only a generic 6 mm piping presser foot set, which seemed to fit correctly. I tried to mount a set of Kwon Hing standard feet, but the outer foot shank on the Kwok Hing set was a bit too narrow (about 2.6 mm wide). The shank opening on the outer foot bar on my machine measures about 3 mm wide. I have since ordered another generic 5 mm piping foot set, and when they arrived, they fit my machine’s outer foot bar. So I ordered some more generic presser feet sets which I will need for the seats in my car, as well as some system 190 Schmetz needles in both “R” and “D” points, but they haven’t arrived yet. At Uwe’s suggestion, I checked my needle plate and feed dog part numbers, and they are correct parts for this subclass model. The needle currently mounted on the machine reads “Schmetz (symbol) 130,” so I don’t know if the “130” refers to the size, or if it is the wrong needle system. Being anxious to test it out, I did some practice sewing on scrap vinyl with Sungard 138 thread. So far, I have noticed two issues: The stitch length control responds to different settings, but the length of stitches produced is shorter than the size indicated on the lever scale. The longest stitch produced is only about 4 mm. The machine seems to sew pretty well in the forward direction, however, when reverse stitching, the stitches become loose and messy-looking on the bottom. I have tired all sorts of tension adjustments, both on the top tension and bobbin case, as well as re-threading the machine per the diagram, but I can’t eliminate this issue. There is a mechanical snapping sound at higher tension settings, too, and I don’t know if this is normal or not (I don’t think it is normal?). I have the parts manual, user manual, subclass publication, and at Uwe's suggestion in another forum post, I purchased and downloaded the CORRECT service manual for my machine here: http://sewingonline.co.uk/library/pfaff-service-245-to-1246.html I haven’t gotten a chance to go through the adjustment procedures outlined in the manual yet, so I am hoping that will resolve my issues. Although these specific issues are not directly addressed in the service manual, I suppose that making all of the factory-recommended tuning and adjustments would be the best way to proceed. Meanwhile, I was hoping some Pfaff experts out there are able to give me some advice on what I should be looking for to get these issues resolved. Thanks in advance for your help! Kind regards, Tim

- 3 replies

-

- short stitch legnth

- loose stitches in reverse

- (and 2 more)