Search the Community

Showing results for tags 'repair sewing machine'.

-

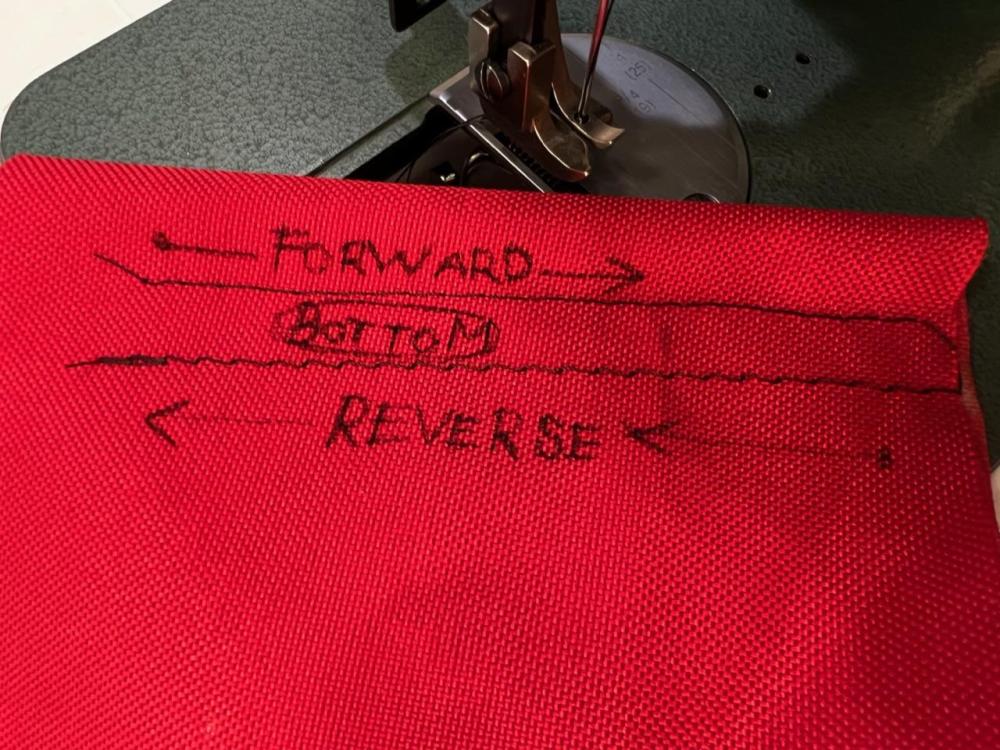

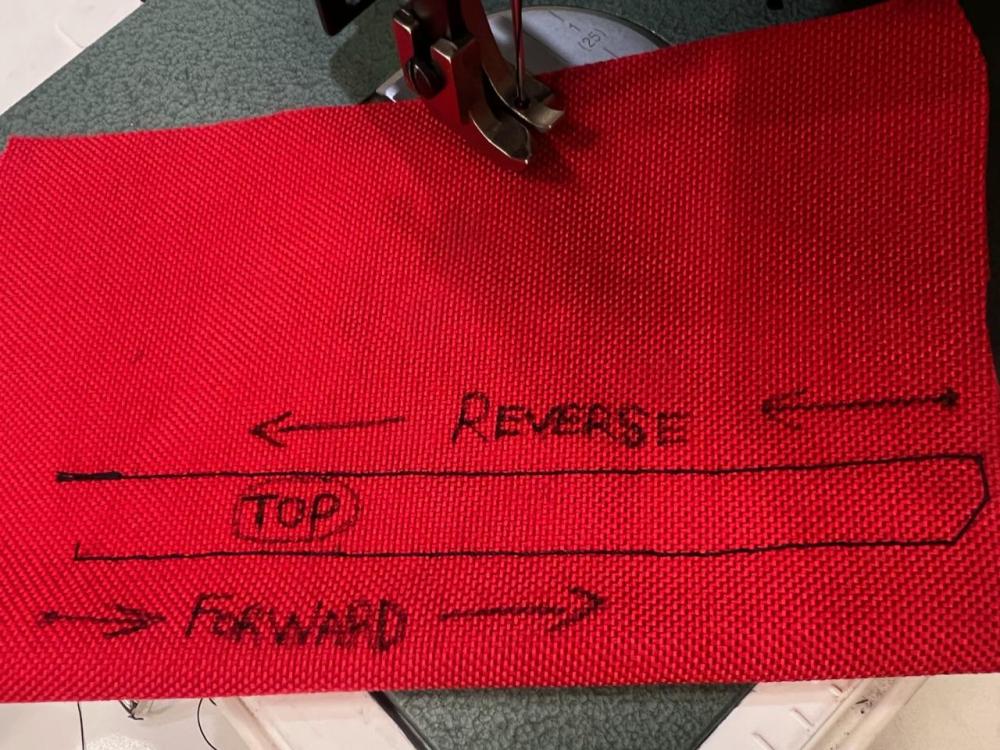

I have a Thompson Mini Walking Foot PW400, essentially what the Sailrite LS-1 was made from. I’ve had this machine for a few years, was my first walking foot, it would sew decent; never had issues I couldn’t learn to resolve on my own. Eventually I started replacing many of the worn out pot metal components with new Sailrite branded stuff. In the past few weeks I replaced the Crank Rod (couldn’t adjust , Presser Bar Track, Rear Presser Bar Track, Actuator, and Feed Rock Shaft Crank. These were either worn with set screw grooves, or beginning to crack due to softer metal. At some point this issue developed. Now when I reverse stitch, the bottom shows bad tension issues. I can forward stitch cleanly, but somehow I lose top thread tension, or the thread is resisting too much when going around the bobbin. Pics of stitches are attached. I use this machine in helibases across the West as I travel constantly for fire in the summer. I repair crew gear, come up with new solutions, or just tinker and make myself and coworkers things. That’s why the portable walking foot is a necessity for me, and sewing is a passion, and also why it’s very frustrating to not have this machine fully functional. And I really just want to understand why this is happening, I’m very invested at this point. What I’ve tried so far: -adjusting bobbin and top tension all over the spectrum. No change after getting in sync for forward stitches. -altering top thread path, trying new spools, new Sailrite feet, generic feet, new retaining ring and spring cap, raised and lowered presser pressure, changed bobbin and case, changed out the entire upper tension assembly and positions. Checked for burs/ damage in entire bobbin area. No change. -V69 nylon and V90 polyester with size 110- 140 needles. Mostly with 2 layers of 100d Cordura or webbing. No change in reverse issue. -timed and retimed the shuttle hook, shuttle housing, needle bar height, inner and outer foot rise and motion according to Sailrite specs. No change after getting everything dialed back in. -emailed Sailrite. They just gave the basic timing vids I already have access to, and suggested a new spring cap. Replaced both with new, no change. -met with a repair guy, he suggested some different timing specs to try that were very different from Sailrites: Lowering the needle bar with hook meeting needle at mid/ upper scarf instead of just above the eye. Having the hook travel a few mm farther counter clockwise before starting motion to needle. No change, and even skipped stitches. I have since gone back to Sailrite specs. -raised and lowered feet, and their forward/ aft positions (few different configs). No change. - slightly moved rocker positions via connection bolt positions in slotted arms that control actuator and drive/ reverse. No improvement on reverse tension. -probably many other attempts at tweaks that aren’t listed here. -watched the entire forward and reverse motion in slowmo many, many times. The only things I can figure now are maybe the fabric is pulling up slightly at needle hole on the thread uptake due to different feet position in reverse vs forward? Or thread dragging in shuttle housing area (maybe due to shuttle driver being too far left or right, or something else)? I am obviously missing something here, I feel like I’ve tried everything and am losing hope and ideas to figure this out. I hope someone can father something from this long post, and I can post specific pics if needed, but the machine timing and tweaks happen everyday. Thanks in advance.

-

You folks are a wealth of information here. Don't know how long I have been lurking in the shadows. Didn't seem I had much to offer with my kind of leather work. But now I come begging. I have read through most every pertaining to this machine to try and get it back to working. My dad thought he was doing me a favor, even bought it from family, so there should be no problems. Yeah, well maybe not very many. She only sewed canvas with 137 and you can see where it was 'fixed' for only that application. I am not asking it to go through 6 oz veg tan. I am working with 2-3 oz, skived leather. It should go through it like butter. I am only making handbags. The top tension unit literally fell apart in my hands, so I replaced the whole unit. Still when I sew the top thread loops pretty bad on the bottom. All the advise I get says tighten the top tension, but there is absolutely no bobbin tension and I know that's not right. After reading anything and everything I could, I do believe the timing is ok, but that is the only good thing. I found a screw missing for the tension on the bobbin. You can pull it out like there is nothing holding it. I replaced those two screws. The felt washer was missing, replaced it and one other thing I can't remember now. But it is the same problem. I am thinking I should just take out that whole unit, bobbin case, hook, etc. and replace it. Is that just throwing more money into the boat anchor? We do not have a service man within 295 miles. I even offered to take it to him, but I can only realistically take the head and he has nothing to run it. It could be such a great machine, I want it fixed so bad. Where on earth do I start? Trying to keep getting my own parts and working or finding someone I could ship it to and be sure it is done right? I know they aren't worth much, lots less than new for sure, but am I going to put more into it that it is worth? I have 101 questions, but I will just stop here and hope some of you will take pity on me and point me in the right direction. (Umm, I make really good fudge, if that helps incentivize anyone Thanks so much folks, Kat