Search the Community

Showing results for tags 'sth-8bld-3'.

-

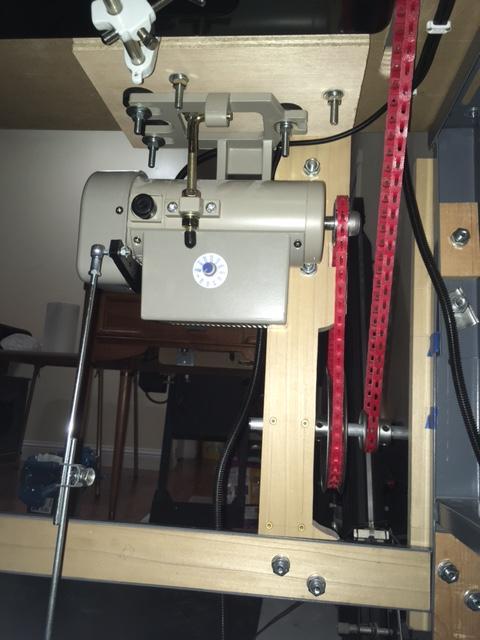

Back in 2018, I got hold of a STH-8BLD-3. I used it for a couple of small leather projects, but without a speed reducer, it primarily it saw use for heavy canvas on a theatre gig I was doing at the time. In 2019 I moved across the country and my art/craft/hobby area had to be colocated with the cats' litter boxes for the past few years. I've had plenty of other stuff to do in the meantime, so I've kept my machines bagged until the last of the kitties eventually passed on. Now that I'm able to eradicate the clouds of fine dust from the room, I've started setting things up again. Regarding speed reduction, I researched the topic on the forums back in 2018, and again recently. After considering others' builds as well as the purpose-made products available, I still chose to go the DIY route. The factors leading to my DIY decision: I felt that I could build a reducer for less than the cost of a commercial product. As it turns out, I can--so long as I'm paying myself in beer. I really really really didn't want to cut or drill extra holes in my table. This was really the biggest factor. Every other solution I'd seen required modifying the existing belt hole or was a new top build. I hate myself apparently and don't have enough problems There are likely simpler ways of accomplishing this, but here's what I cobbled together with a band-saw, drill-press, dremel and hand tools. Maintaining the original angle coming down from the hand-wheel prevented the need to modify the slot, but made for a long stretch. I haven't measured each belt, but the two add up to ~9ft. This worked to apply load to the pillow-blocks in their strongest direction, directly into a leg; though, beefy as they are, I doubt it much matters here. Note, the belt going to the machine head is on in the wrong direction in these photos. The vertical boards, and the horizontal bit inside the cross-brace (pictured further below) are all 1x4" poplar. The slots for the bearing mounts were done on the drill press by setting a fence to slide the board along while drilling a LOT of holes with spade & Forstner bits, then cleaned up with a chisel. The bolt heads and spring washers sit in a pocket and can slide up or down. For the motor mount, I plotted out the base on graph paper and made a template to shift it left and back enough to be out of the initial belt line and to not interfere with the original bolt locations. This ended up being a really tight fit for belt adjustment at the end; if I did it again, I'd position the motor a quarter to half an inch forward. This worked out because link belt is forgiving, and I designed this to allow for adjustment at the pulleys in addition to the motor. It's two pieces of 1/2" birch ply, with the motor bolt heads countersunk and hidden between the boards & table. These bearings are adjustable, however, the ones I received were very stiff initially. Even after greasing, I worried I'd break something while trying to get them aligned. I ended up bolting each pillow-block to a 2x4 clamped to my bench and worked them around for a while with a 3ft rod until they loosened up. For the axle, I cut steel bar down to size & chamfered the ends. Using a dremel and file, between bouts of sciatica, I ground about the ugliest usable flats that I'll never show you for the pulley & bearing set-screws. Because my flats are dodgy, and because both pulleys have key-ways & I'm not using keys, I balled up lengths of electrical solder to fit comfortably in each set-screw hole, which mushed down and engaged nicely. This also prevented the set screws from extending into the empty key-ways where they'd be unsupported & weakest. Once I got everything tensioned, it all moved nicely by hand and easily penetrated several layers of heavy canvas. I'll get some leather under it later this week and see how it does. I suspect I may want to move up to an 8" pulley and designed with this in mind, however I may look to a larger handwheel first if I still find it too fast.

- 9 replies

-

- speed reduction

- sth-8bld-3

-

(and 1 more)

Tagged with: