Search the Community

Showing results for tags 'timing adjustment'.

-

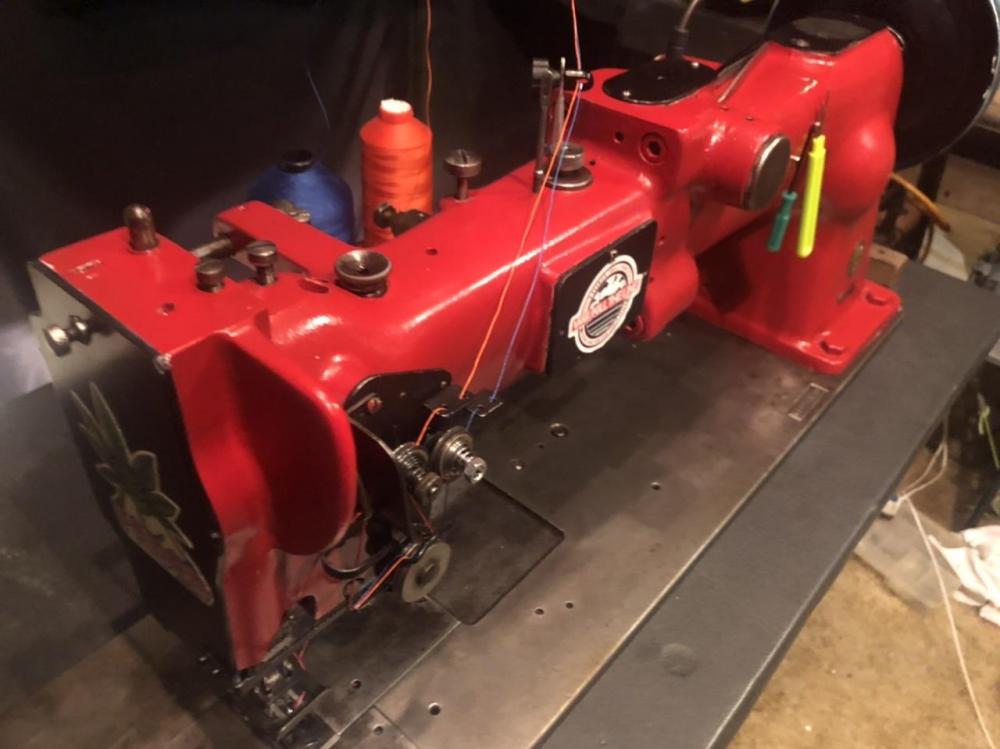

Hi all! I've got myself a Pfaff 1245-706 machine, and thanks to reading other posts on this forum I've been able to (mostly) get it cleaned up and running. When I say mostly running I mean everything seems like it's mechanically smooth, oiled and greased properly, I've spent a lot of time making sure I'm threading it properly and testing out thread and needle sizes to get the right fit. I've finished making a tote bag which mostly went fine, when I say it's running I mean that with enough fussing I've had it making nice stitches for long enough to finish a project. The problem I'm having now (and a bit when I did my first project) is that it seems like it's incredibly easy to throw the timing off. To the point where I can't really re-attach the drip tray under the table or cover the gears that spin the hook race because I need to access and adjust them so often. I'm following the steps outlined in this video starting around 16:36. So I'm getting the needle to the lower dead point, loosening the two screws on the small gear, and adjusting so the hook meets the middle of the scarf when the needle in about 3mm up. And this works... Kind of. Like I said before, I was able to the machine working nicely long enough to finish a tote bag, but basically any little hiccup - tension slightly being off, bobbin winding being a bit too loose, etc. results in the timing being thrown off. Sometimes if there's a big thread tangle I'll have to reset the safety clutch, but often I'll have to adjust the timing without the safety clutch needing to be reset. I can't quite figure out how this happens, as I'm re-tightening the screws on the small gear after re-timing. One guess I have is that this is a tension issue. The thread is usually quite hard to pull through the machine when it's threaded. When I had it working properly the tension dial was set very low and that was producing good stitches, but it seems suspicious. That thread wasn't particularly heavy (it's unlabeled so I'm not sure of it's size) I was sewing with a system 190 size 130 needle which was a good size to have the thread pass through the needle easily. I'm experienced enough with sewing that I think I can match a thread and needle size pretty well. I'm currently trying to set it up to use a heavier thread, labeled as Cansew CBB138 nylon. I'm using a 160 size needle and that seems about right, but again just pulling it through the machine when it's threaded and the foot is up/tension discs loosened, it's in there quite firmly. I wonder if I should be adjusting the way I'm threading, like maybe just going through a single loop on the top finger instead of winding it around a few times like they recommend in the manual? This is my first time working with an upholstery machine and thread this heavy, so I'm not quite sure if it's normal to adjust the threading path if tension is too high, or even if the settings should have to be so precise to avoid jams and skipped stitches. Every other machine I've used from domestics to an industrial Pfaff 563 was a lot more forgiving when it came to threading and tension, very rarely had thread breaking or skipped stitches so I'm curious to hear thoughts on what might be happening with this 1245 machine. As of right now with this heavier thread, it's not really jamming or breaking thread, but after the first few stitches the timing seems off and stitches are no longer being made properly. I can provide pictures if that helps at all, thanks in advance!

- 14 replies

-

- timing adjustment

- troubleshooting

-

(and 1 more)

Tagged with:

-

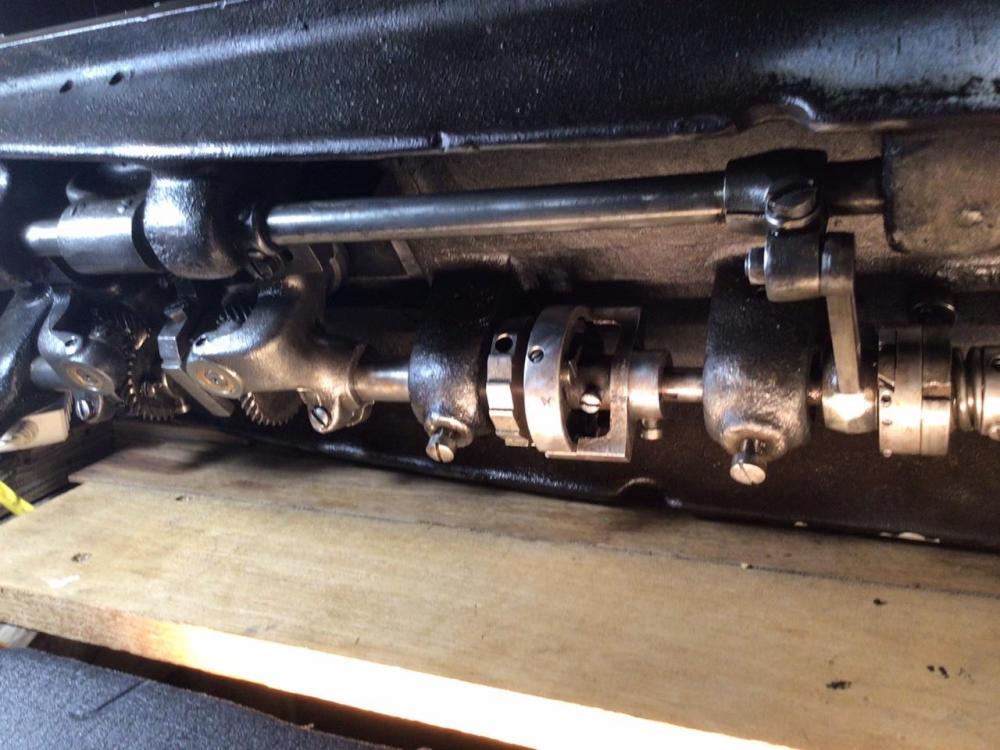

My 145w204 had been sitting since the 70’s when I purchased it a couple weeks ago. It had no rust, but was covered in decades of warehouse storage, spiders, and varnished oil. Machine wasn’t seized, but very close to it. Mainly old oil that had turned to glue. Got it tore down and polished everything clean and smooth. Stitched like a champ. Belt came in and I swapped out the old dry rotted one. Still worked, but not for long. So I put the new belt on exactly like the manual calls for, and I’ve done it 50 more times to be sure. Long story short, everything looks perfect, hooks to needle, runs smooth and quiet, my problem, the feed dogs will not keep time with the needle. At zero feed yes, they line up, start adding stitch length and forget about. Almost seems like something is 180 degrees off. I did not disassemble anything on the eccentrics, just clean and oil. I did check for loose bolts but all was good. So that’s the the gig, my feed dogs and needles won’t time, but everything else looks good. Any advice, hints, or means to a solution would be greatly appreciated. Thanks.

- 2 replies

-

- feed dogs

- timing adjustment

-

(and 2 more)

Tagged with:

-

I have a consew 118 and I am having trouble with getting it to sew. When I got it the needle bar was striking the foot so I did a rough adjustment. When I first tried to sew it worked for about six inches then it started to jam. I bought a servo motor for it to make it run more manageable. Before I install it I have been trying to readjust the needle bar height and cycle it by hand. I can't seem to get it to sew again. There doesn't appear to be any way to adjust the hook timing so I'm not sure what to do.

-

I have an old Adler 20-2 that "crashed" and the needle and holder were pushed out of position. Does anyone have set up / adjustment information? My wife and I have a stable and many halters needing fixing.