Yanni

Members-

Posts

71 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Yanni

-

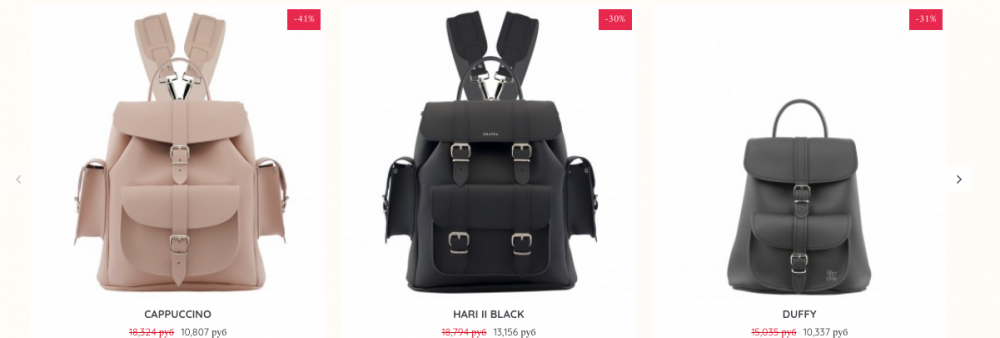

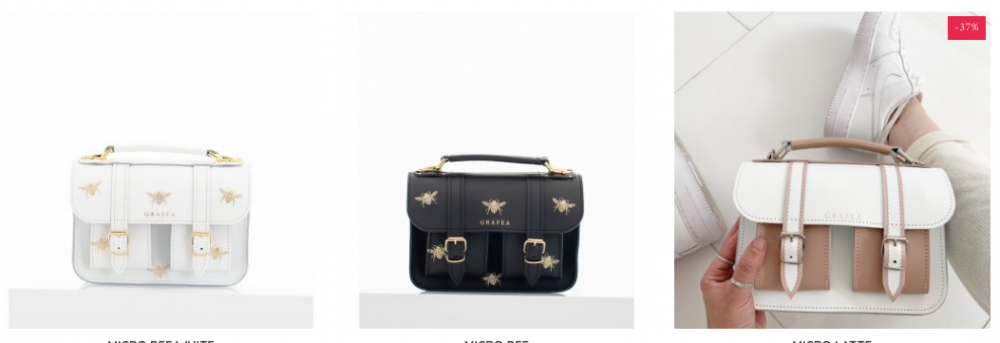

We are a leather bag manufacturer in Manchester UK ( please see attached what we make ) and I am about to purchase some more sewing machines. We currently have 3 x Adler 869 normal cylinder and 1 Adler 669 binder. Can you please advice whether there is any reason to buy a 669 with the smaller cylinder? What are the advantages of the smaller cylinder? Both machines are more than powerful enough to sew our split medium hardness leather of around 2mm and make our satchels as we use 130size needles. What would the small cylinder of the 669 allow me to do that the slightly bigger cylinder such as the 869 will not? https://www.duerkopp-adler.com/export/sites/duerkoppadler/commons/download/public/869/869_de_en_fr.pdf https://www.duerkopp-adler.com/export/sites/duerkoppadler/commons/download/public/669/DA_669_deen_09-2019.pdf Thanks

-

I need the tool that this guys uses, to fold skived leather edges, where can I get one please, anyone have any suggestions? Thanks.

-

I need the tool that this guys uses, to fold skived leather edges, where can I get one please, anyone have any suggestions? Thanks.

-

We've got an Adler 269 at work. I get really good tension on forward stitching however on the reverse it bubbles up underneath as if the top thread is not pulling enough. I need to tighten up the top tension very high in order to get anywhere with the bottom but without perfect results. What am I doing wrong? Thanks

-

I am wondering if someone has the contact number for Efka Technical in Germany, I think the man I need to speak to called Wilfred or something. I have seen it in an old post but cannot find it now. Thanks Yanni

-

PROBLEM SOLVED! Thanks a lot for all the replies, I called an engineer from the factory next door and sorted it out. He basically told me if there are skipped stitches check the hook first! What happened is I had for sometime a lot of play on the feed dog because of a non original spacer next to the feedog. That was kept of breaking needles for a while due to the play of the feedog and the needle not always hitting the centre of the feedog. As a result it had also blunted/rounded the tip of the hook. I also found a small piece of broken needle inside the hook and also had to move the hook assembly as close to the needle without touching...all this 0.10mm business is rubbish...you just get it as close to the needle so you no longer see any light behind with the magnifying glass. Then we sharpened the bottom up and inside tip of the hook( never the outside he said) to make it like a needle point and it now works again like a dream, no more slip stitches... Thanks again...

-

Thanks, all the adlers in factory are identical and use the same needle/thread. I don't use the factory settings for the timing as I found them slightly incorrect. Again the other 3 are working fine with my settings. I will try another bobbin tomorrow and see what happens...

-

Hello, We have 4 x Adler 269-373s in our factory and one of them skips stitches just one at a time and totally at random. I have done the timing in all of the other machines so I am quite competent to sort them out but the last one I can't work out what is wrong with it... The puzzling thing is that it skip stitches on straight lines usually you get missing stitches on curves etc when the leather is stretched and bends. I've got an EFKA motor on it, hook is brand new, and checked distance between hook and needle is great, I have tried various tensions, for both thread and thread spring, alter tension on the bobbin....really puzzled..also machine restricted to 650 max speed. Most of the parts are brand new original Adler too I bought from Germany( spend £1000 on it recently ). The only thing I can see is the thread flying out a bit more when it misses the stitch and I've got the feeling it does it either when decelerate or accelerate. Any suggestions? Thanks Yanni

-

I have a Fortuna Skiver and no matter what I do the bell knife's edge is not sharp enough. I've got the feeling it has to do with the angle of the sharpening but cannot figure out how to change that. I have change the sharpening stone with a brand new original Fortuna, I always sharpen the sharpening stone with that special wheel tool. I'm confused....any help? Thanks

-

Thanks Uwe...will check them out.

-

I bought 4 Adlers 269-373 machines from a known used retailer in the US and there were all rubbish! I mean, I spent another £3000 here in the UK from College sewing to buy the parts to make them work properly. The hooks were bad, they had even modified the carcasses to fit non-adler parts( non-compatible), extra screws were holding bits together, needle plates were all worn off...all sort of things. I still need a few bits but I'm tired paying genuine adler parts £125 for even small bits. I did buy some original Adler hooks and some italian compatible ones but I'm wondering if anyone knows any shops in Germany, Europe or the US that would sell compatible parts? I have bought a SIECK 269-373 from Germany which is basically a copy of the Adler so someone out there should be selling non-genuine parts....Can you help?

-

I'm trying to find a way to mark an outline of a pocket so the ladies in the factory can sew the pocket on. I usually have a knife with blunt edges that we mark the leather but when it has this faux fur on top as in picture, I cannot find a way to mark it. Our hot foil machine goes only until 120 degrees Celsius so it doesn't really mark it. When I use a pen, the marking is hidden inside the fur and cannot be seen. Any ideas?

-

Where can I get a knee lift air switch or a pedal one from? I've got an efka servo motor installed so unlike in a clutch motor there is no stop on the heel press. Thanks.

-

My Adler 269-373 came with a pneumatic attachment as pictured. Can i buy one of these and make it work? https://www.college-sewing.co.uk/KHM-700-1H-HEEL-ACTION-AIR-TREADLE-ROD Thanks Yanni

-

SKIVER: fortuna-type-50-pag-df I just replaced my worn out feed roller on my skiver but I discover a problem. The axon coming from the motor that feeds the roller is not long enough or the feed roller is shorter so it wears out the attachment of the feed roller. Please see the video: The feed rollers I use on this fortuna skiver are compatible, they say Made in Italy and they have the number 801 on them. Am I using the right feed roller as it gets wear out really quickly. Have you got any idea where to get the right type? I bought mine from here: http://www.sieck.de/en/machines/skiving/leather-goods-and-automotive-interieur/details/5332/ Any help would be greatly appreciate it as I'm a bit stuck really!

-

I'm looking to do this with a sewing machine , not by hand David as our bags are sold in the hundreds here in the UK. Our profit margin does not allow for hand work on these so I was looking for a quick way...no glueing or using pricking irons.

-

I am trying to sew a pocket by making an external stitch like in the photo. How can i do that while the bottom leather stays 3mm from the guide edge especially around corners? I can sew the pocket if both layers top and bottom edges are against the guide but overlapping each other i cannot find a way to do it without glueing the two layers...any help? Thanks

-

Thanks for the replies, I need a splitter that will split leather down to 0.2mm thin. All these machines quoted go down to only 1.2mm and not thinner. I need the splitter to make almost paper thin rectangular pieces to wrap around our briefcases's handles. At the moment I use our skiver and have to pass the pieces many times, splitting around and then in the middle the pieces that is a pain!.

-

Thanks...I need something slightly more industrial really, small but it's for our factory in England. Thanks

-

I am looking for a small leather splitter to make very thin pieces of rectangular leather for wrapping around briefcase handles. Can someone put me to the right direction? Thanks

-

Thanks Tor, The reason I've asked is because I already bought two AB321 motors from SIECK for only 570 euros where they charge me nearly two hundred euros more for the same motor here in the UK. I've found programming the AB321 was dead easy after following the instructions here: I've also called Manfred and helped me with slowing it down. If the DA321 and AB321 are identical that's great but was wondering if the motor provided by sieck is lower torque than on the DA321 package although I haven't seen any problems with our machines. You've said: I paid about 800 dollars (the Norwegian krone; NOK is very high against the dollars) for my Efka DC 1550 (with DA (AB) 321 control and position head) motor included tax and shipping from Germany What is the German dealer you bought your motor from, I am trying to find a dealer that sells same price as SIECK as I can't get hold of Andreas at sieck for some reason, they do not answer their emails or phone!. Thanks

-

Tor, Three Questions if you don't mind: 1. Do you know the difference between DA321 and AB321 Efka controller? 2. Also, where about in Germany did you buy the motor from please? The want to charge me $1130 for the same motor here in the UK! Finally, can I add a foot lift on this controller AB321 or DA321 and how do i do that or what is it compatible with this Efka combination? If you can shed some light on this would be great. Thanks.

-

Tried them, they are out of stock. Another company called Advanced Sewing Technologies, Corp in Pittsburgh have a few. What is the best way of transporting these heads...has anyone got any experience ? Thanks

-

I'm after a few Adlers 269-373 machines for our UK factory. Either complete or just the heads would do. Can someone put me to the right direction, I usually buy these either in the UK or from Germany( sieck.de) but can't get hold of any at the moment. I've tried a chinese clone from SIeck but it's not as smooth as a used genuine adler and had to change a few of the parts too. Can anyone from Germany, Austria or another european country put me to the right direction for a dealer selling used ones. Also, where I can buy EFKA motors in Europe? Thanks Yanni

-

Adler 269-373 Needle Bar Position Adjustement

Yanni replied to Yanni's topic in Leather Sewing Machines

Yes, it is, just move it a bit to the left so that it is centered and discovered they have removed the washer/spacer from the right bolt that holds the feed dog assembly. Ordered the parts and will hopefully work fine after. Thanks Bob.