-

Posts

5,687 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by Constabulary

-

-

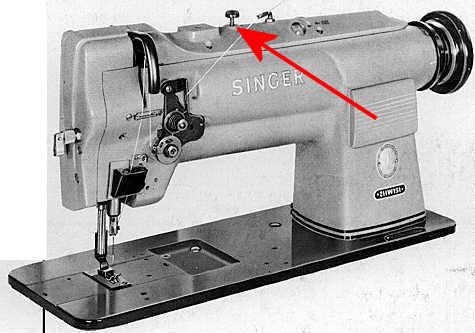

I don´t think it is a Singer only because it has Singer tag. If it is a Singer look for the serial number an post it here so we can try to figure more.

Pfaff, Adler and Seiko made similar machines of this class. If it was a Singer it would be a Singer 17 but again I personally doubt it is Singer made machine.

The stitch length lever look kinda Pfaff-ish - like from Pfaff 25 machines but not exactly the same....

I would almost say it is a Japanese made machine of some kind / brand.

-

-

-

6 hours ago, kgg said:

According to the parts manual there are two screws (position and a set screw) holding the handwheel on

true - as on most machines. Problem is IIRC that the shaft bearing (272142 I think) is inside the hand wheel or the casting and my buddy said the bearing is THAT tight on the shaft or inside the hand wheel / casting (glued or shrunk fit) that you cannot pull it of w/o damaging other parts.

Maybe CowboyBob knows better 😉

-

I don´t think it is possible except you drill a hole in the shaft and cut a thread. but IIRC it is almost impossible to remove the hand wheel from a 211. I have a 212 and was not able to remove it. A friend tried to pull off the hand wheel on his 211 with a gear puller and bent some parts around the thread lever.

However, maybe you can make a sleeve or spacer ring that goes over the "hub" on the hand wheel.

-

Here it is.

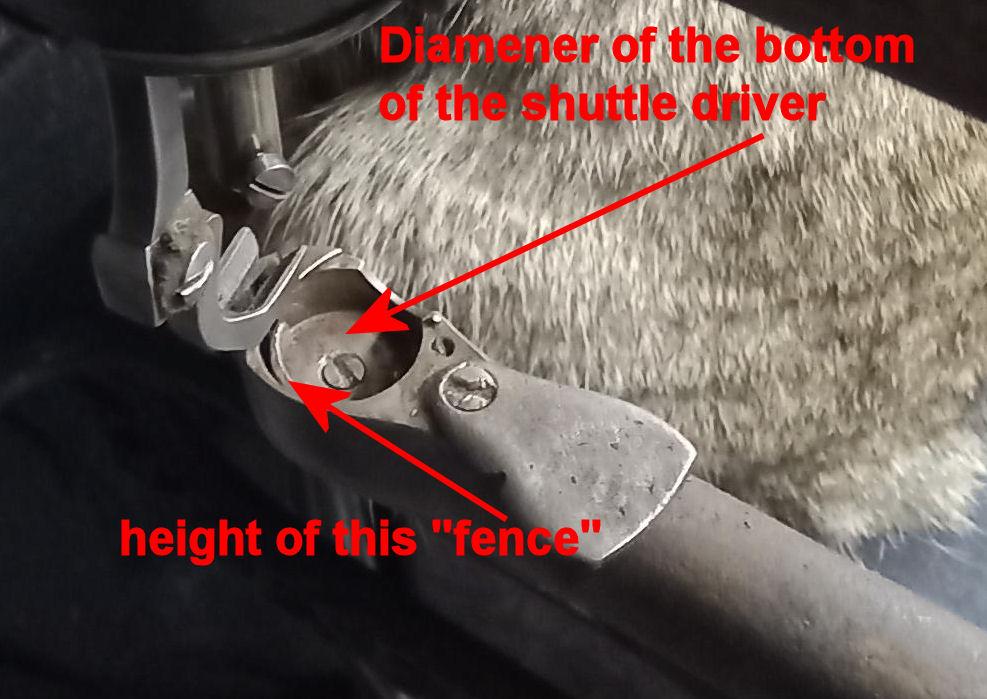

The Seiko SLH is a clone (more or less) of the Singer 7 and the manual includes the needle hook timing so its good to have.

Singer 7 CLASS Manual.pdf Singer 7 Seiko SLH-2B Instructions Manual.pdf

-

aaaah I´m toooo much "singerized" I guess... 🤪

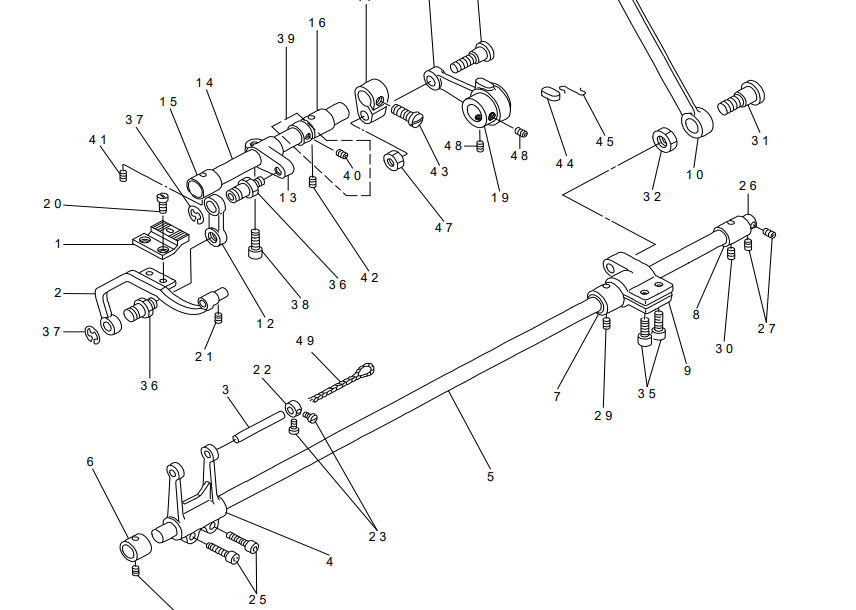

its a bit different on the 243 as it seem but you can move the feed dog holder sideways.... but its a bit more difficult as it seems. Looks like you have to loosen the 2 screws #25 but an actual picture of the underside of your machine may give us a better idea....

-

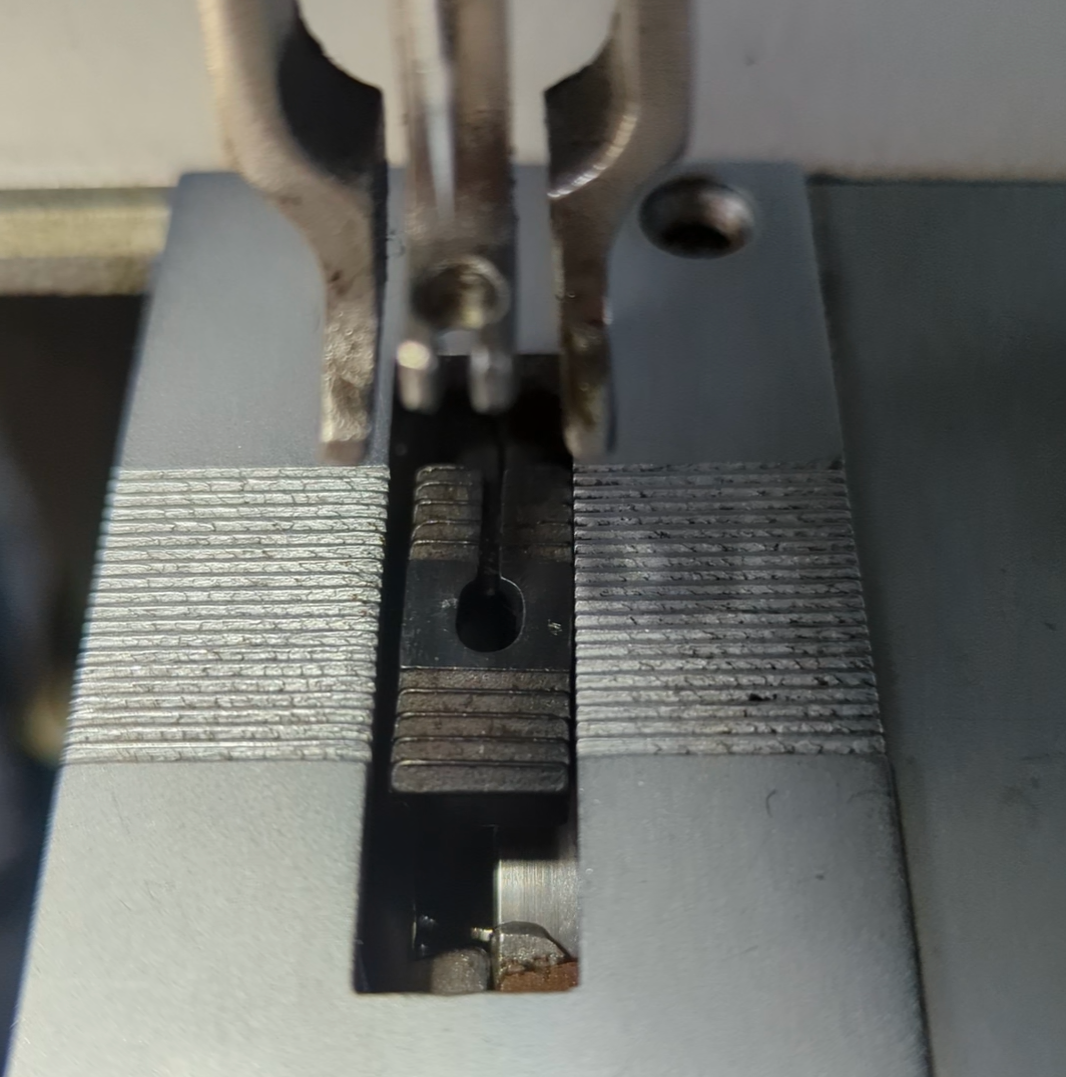

You can move the feed dog holder a bit sideways.The feed dog holder is attached to the feeding rod with 2 pointed screws (one on either side).

When I look at this picture I think the feed dog seems to be misaligned. What I would do first is loosen the 2 feed dog screws and try to align the feed dog.

Then I would try to move the feed dog holder to the left.

It should be the same as on Singer or 45K or Adler 104 flat bed machines.

I´ll take pictures tomorrow...

-

I´m aware of that, I have several, incl a 212 Singer (2 needle version of 211) which is basically the mother of your 255. Mine also has a reservoir under the top lid. But sometimes clone machines come with upgrades. So if you need just a drip pan with no oil reservoir you have to look for one with enough depth. I´d still contact a Consew dealer and order one. Maybe these folks in Seattle:

-

is there an oil pump on the underside or are there hanging wicks into the pan that suck up oil (I don´t think so)? So if not it is a manual oiling machine (basically). I think the hooks run in an oil bath but is is a closed system. I think you can use random oil drip pans. But maybe you can post pictures from the underside of the machine.

-

I have shipped a patcher from Germany to the US in a custom build crate but that was just the head w/o stand and it is A LOT OF work cause you have to do a lot of internal bracing so that the machine cannot move round in the crate. BTW shipping the DIY wooden stand makes no sense. Not worth it IMO.

Other that that look for a double or triple wall cardboard box large enough for the machine + 2" - 3" space to all sides of the machine and fill the space with cut so size Styrofoam boards and bits. Do not use bubble foil or Styrofoam chips. The machine needs to sit very tight in the box. To save on the box size (shipping size) I´d remove the arm lever (just two pins that go out from rear to front) the hand wheel, front wheel hub and wax pot. Maybe the from tension and lock screw too (better safe than sorry).

I have shipped machines with UPS to the other side of the pond and they all arrived intact but I have some experience in shipping & packing up heavy things.

-

I think it uses just a "plain" drip pan and a a drip can with oil reservoir, right? I guess the one for the Singer 211 should work but I´d check with a consew dealer they may have one or can order the correct one. See pictures here:

https://consew.com/products/consew-model-255rb-3

Or check the parts list and google the parts number and machine model

-

2 hours ago, Wyowally said:

Check spring has an external little coil along with the standard U-shaped bend

does not sound like a 7-34 - just from what I have in mind it sounds a bit like Singer 7-10 (or similar) thread regulator spring - but I´m just guessing...

We need pictures I´d say. 😉

2 hours ago, Wyowally said:Timing seems off, Hook/shuttle, bobbin case mechanisms appear sloppy

Barrel hooks always appear a bit sloppy cause the thread needs to slide around it.

-

if it was me I´d go with the 67-GA-373. Have an eye on the timing belt. The old brown ones tend to crack and fall apart with the time. If yours is bad check this tread:

-

if it is a CLEAS (please post pictures) then there were at least 3 different sizes off bobbins / hooks.

This is a pic from a later model but IIRC the hooks remained the same event until today but I have to admit I have not much experiences with the colibris.

CLAES RPX, Modell 200 and newer models I know more of.

-

I´m collecting Vietnam War items for many decades. If it was me I would not wear them. first of all when it is a common wearable size (f.i. 9R, 10R and so forth) I think the collectors value is higher than the value of wearing them. If you don´t care (your choice) keep in mind that the rubber sole is 55 years old ant it may crack sooner or later when wearing. If it was me I´d sell them to a collector (maybe on Ebay) and buy a new pair of jungle boots.

-

I guess you mean the stitch length dial knob. I think I have a metal one here, I´ll check that later....

Or do you mean the Zig Zag knob?

-

how about a screw extractor. not sure if it works but IMO it one of the last options you probably have.

There are other model video show just a random one.

-

if it is not necessary to remove the shaft better leave it where it is. such actions sometime cause more damage on parts that most likely are no longer available.

My 2 cents.

-

post some pictures. I once bought front shaft for my 29K71 restoration from College sewing in the UK and I remember the gear was very tight on the shaft but it worked. But I had the OEM gear.

-

Please post a good clear picture from front and and back of your machine .

-

-

It basically is a modern version of the Singer 45K

Parts list an manual can be downloaded here:

https://leatherworker.net/forum/topic/104255-neels-saddlery-tension-issue/#findComment-696717

-

Have you taken apart the press? Maybe the solution is simpler than you think. As I said before I once replaced tool holders with a round long nut. Its a quite simple part. Worth checking I´d say. What is the outer diameter of the tool holder?

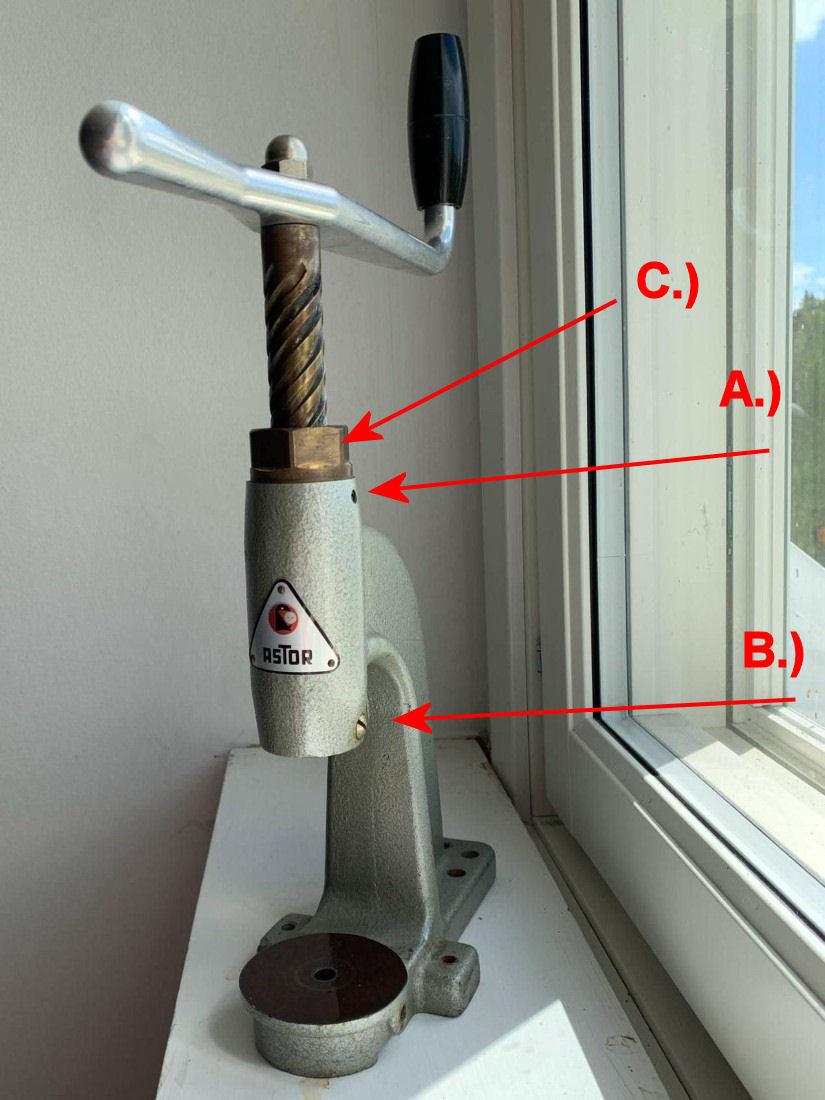

A.) is a guide screw for the tool holder, the tool holder either has a slot of a flat site where it slides along the screw.

B.) is a lock screw for the big brass spindle guide

C.) is a spindle guide - all spindle guides I have seen are right threaded so it should go out left.

But C could be very tight.

EDIT:

quote from the text on this website:

QuoteWerkzeuge für Pressen mit M6 Gewinde - wie viele Maschinen von Astor, Stocko, Daudé - finden Sie unter "Werkzeuge M6"

Tools for presses with M6 thread - like many machines from Astor, Stocko, Daudé - can be found under "Tools M6"

Have you checked if you can screw in a plain M6 screw?

Singer sewing machine identification

in Leather Sewing Machines

Posted · Edited by Constabulary

needle plate and feed dog are missing, not sure if the shuttle race and cover are complete but I´m almost certain that Singer 17 hooks would work IF the shuttle race is complete.

So since you are from Hungary (former east block / soviet influenced) I would bet that it is a East German / GDR made Tetxima 17 or Köhler 17 (or maybe even a PODOLSK of some kind).

But I only can guess.

Best bet or parts - try Singer 17 parts or Seiko TE-6 parts.