joeyrsmith

Members-

Posts

83 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by joeyrsmith

-

Want to say first to all who have given me great advice. On my 211g there is a set screw on top in the middle of the machine as you know. Turning it tightens and loosens pressure. I am use to home machines that have the little plunger which I can guage the pressure pretty easy. As this is my first BIG BOY machine, I am having trouble figuring out the pressure. It is leaving some underneath marks. I mainly do bags and such. So my leather will be 2-3-4 oz doubled for seams and the like. I back it off and the dog feet marks disappear but I still get a impression about 2mm square at the needle exit point. Has me baffled. Thx again guys and hope to contribute someday when i get more experience.

-

Ok thx pcox That is what I was doing then. Tripping the clutch. Is the stitch adj unit in the front head part of the machine? I have no parts list or schematics. Which I think I will search now for. thx Joey

-

Hook/needle Motion. Exact Movement? Video

joeyrsmith replied to joeyrsmith's topic in Leather Sewing Machines

Ok wizcrafts, that helps me understand more. The guy I got it from had it all messed. So, I just got alittle worried on some things being new to Industrial Machines. Thx for the input. Joey -

Singer 211W165 No Safety Clutch?

joeyrsmith replied to joeyrsmith's topic in Leather Sewing Machines

Yes that is mine exactly. So, pcox I am guessing that if the ball drops into the dimples that is the "safety" part and the deck button reengages it. It looks so different to mine considering they both are Singer models close to one another. Plus, if I adjust stitch length it messes with the clutch setting and I have to rotate several times to get it back to timing right. I do have it working fine now. Just kinda irritating if I want to change stitch length. thx Joey -

pcox, thx

-

Hi again, after watching Eric's video on the safety clutch from the 111w thread from a year ago I was surprised to see that my 211w does not have one, Could someone please tell me why? Is it located somewhere else? Maybe further up the shaft? Very strange. thx Joey

-

Good morning. Still learning this 211g. Fixed my saftey clutch/stitch problem I think. Working and sewing fine this morning with proper motion from what I can tell. After lifting machine and hank cranking a bunch of times to see how it all works I concentrated on the hook going by the needle. In the beginning I could have sworn that the the needle was on a downward movement when the hook came by to catch the thread. But this was not really studying it hard. Just at a glance. Now after some issues that you all helped me with I noticed late last night that the needle is all the way down and on the upward path the hook needle guard comes by and I would say that it does barely, just barely touch the needle then the hook comes by and grabs thread. I would say that it must be 1/64 or less. Maybe a human hair when they touch. Is there a video or diagram on this movement. My manual talks about a ton of adjustments but nothing on this movement. Thx again gang. Joey

-

CD, using the manual, I am pressing the button one the deck. It says to wait until it drops then turn until stitch length is set. Lifting machine I see it the pin drops into a cutout on a wheel which keeps the hook from moving. After that I do not know what happens. I do not see a clutch reset button. Sometimes when I have the button depressed and start turning for the length I here another "pop or heavy click sound" After I release the deck button it allows the hook to rotate. I had to do this a bunch of times before the needle and hook were in synchronization again. This morning it seems all good. But I want to know this machine for I will keep it a long time I think. I was worried last night that the hook/needle timing was off, because of the way the needle was dropping and the way the hook was going by. Still trying to find a video or detailed info on the EXACT way that motion works. Thx

-

Ok will do. Thx

-

pcox, Please elaborate on the "safety clutch". Very new to industrial machines, I think I read something on that in my manual but have no idea. thx

-

Guys and Dolls, After adjusting the stitch length this afternoon, I have had some strange and spooky haunted things happen. Has anyone had their machine go "out of time" Dont know if thats the right term. My hook was 180 degrees off until I hit the button again to adjust the stitch a little which made it come back to proper position. Then it started to fray the thread and create birdsnest. Frustrating considering I was sewing great all morning. Kept trying to adjust stitch length with very weird and haunted effects. Then after 3-4 times it broke a needle. Titled it up to take hard long look and decided to give it a break becuz football playoffs started. Any ideas on how to rid it of demons? Joey

-

Singer 211G Bobbin Case/hook Lube

joeyrsmith replied to joeyrsmith's topic in Leather Sewing Machines

Thx again Eric. You Da Man! Problem solved. Peace out. Joey -

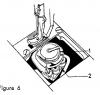

Hi guys, Quick question on this procedure. After looking at the manual, I am still a little baffled on the location points. Heres a pic of my bobbin/hook and a pic of the manual. I see where the felt wick is and is almost black with oil. Its the case part that is throwing me. Could someone help define the oil point. Thx JOey

-

Ok making alot of sense now. My 1st walking foot. Have a big smile on my face. One last question. On the handwheel, they have the stitch length as A B C D E. Plus a little arrow with + and - mark. Its common sense for the stitch length, but what exactly and the numeric equivalents for the letters? My manual does not list anything on it. Thx again, I am just about there. Joey

-

Ok, happy to report. Got it going real good now thanks to Erics little comment "To ensure your bobbin thread is in the tension place a finger on top of the bobbin, pull on the bobbin thread. This will pull the bobbin thread under the tension spring" That was the problem, thread was not under the tension spring. A little more fiddling and I am good to go. Thx Eric and pcox. Eric, so should I hand crank until its at its closest point then move the J-hook closer? Thx

-

Thx. Eric, My latch oper contact point is not as tight as the pic you provided. Meaning, the little hook part is at least 1mm apart from the contact point Does that make a difference? Is the adjusting you mention the J-shaped hook with the set screw?

-

Hi there, got a 211g165 last night. Found a very small pulley which went on great with a shorter belt. Works like a charm. But!! After I get a bobbin in and positioned the right way and the threads ready for sewing, it will sew nice for awhile and then the thread keeps popping out from under the bobbin projection which then it gets tangled up and hard to pull the fabric out to snip the threads. Especially after I cut thread to start a new practice piece. The bobbin thread keeps coming out from under the bobbin projection. I have the plate pulled back so I can watch whats going on. Sure is slowing the process down. having to keep watching that the thread is under the projection. When it does pop over and wrap around some I have to cut thread and untangle. What and how can I keep the thread from popping over the projection? What am I doing wrong please? ANy ideas will be appreciated. Other than that I finally got it tensioned and oiled up properly and sews great slowed down now.

-

Very cool. Learning more every minut. Thx

-

Any recommendations on servo motors Bob? Makes, models, etc. Just servo motor, not a larger wheel or belts? Thx for any input.

-

Hi guys, been a little while. Been busy hand stitching! Just got hold of a Singer211g165. How can I slow this beast down? This is my first walker. So I am still learning this type of machine. I do a lot of messenger bags and clutches,wallets, etc. Any advice on needles, thread, etc would be appreciated. Thx Joe

-

Thx guys for the input. billymac814. I am using oil tanned leather. So I can not really finish the edge like I would for my gun leather with top grain. Last night (4/13) at my market where I sell my goods, I sold 3 messenger bags with that stitching and they all loved it.. billymac, I like your suggestion on the extra backstitch. I will start doing that. needles. I like your idea on the nick to sink the thread into the leather. Its strange, I know the from the comments and the saddle maker that what I am doing is not proper. But, the customer loves it. Go figure. I think I will still do it, but with the extra backstitch and extra go around the edge will help in longevity for the piece. Then again, I will also do some pieces without the outside wrap around stich and see what happens. I will report all final outcomes to you guys. Thx all Joey

-

Thx Ferg, I have seen so many uses of this that now I wonder how it started in the first place Joey

-

Hey gang, been awhile since last post. Quick ? on edge treatment. I ran across a saddle maker from the UK at a art show I was doing and had a great conversation with him on leather work. On my messenger bags and utility bags I wrap the thread around the edge for what I thought was extra enforcement. He told me that "while it looks good and may serve a purpose, it is not correct" Told me that if the bag is used alot "I hope it is, so I make them bullet proof" the thread will wear out there and cause problems. I do see the reasoning there, I just really like to do the edge treatment that way, and use it as a selling point with my customers. Here are a few pics. What do you guys say. All mighty leather pros? thx JOey

-

THX for the tip. Used it again tonight and again started to uncontrollably dance about the room by myself. Remember Billy Idol? "Dancing with myself" That was me.

-

Hi everyone, been awhile since posting last. Just got my new round knife. Man what a difference I am on cloud 9 right now. Can not believe I waited this long to try one. Will never go back to the past way of using a utility knife. Just wanted to jump up and down with like minded people. Did that last night in the workshop with nobody around. Was not that fun. So I had to post it. Anyway, everyone have a great day. Joey