superpacker

-

Content Count

137 -

Joined

-

Last visited

Posts posted by superpacker

-

-

Good tip!

-

Using Uniters edge paint. Thanks!

-

I’m making a wallet out of saffiano calf. Will be use edge paints. Besides it’s hardened grain side, the textured leathers don’t seem to like being beveled. Any tips? Or should I skip beveling, get a perfectly flat edge, and build up a round edge with layers of paint?

-

Odd size, I know. Anyone have one they could share?

-

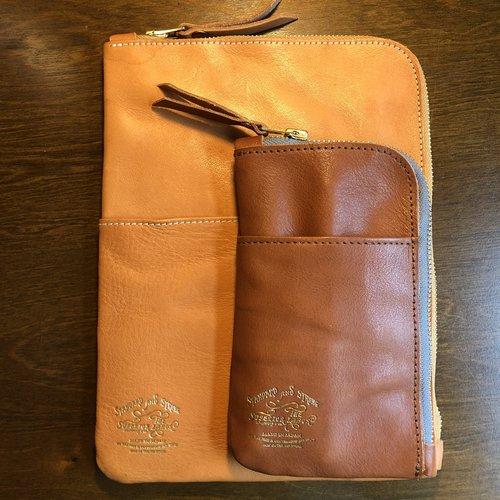

Has anyone made one of these half zip soft folios before? Looking to make one that will hold a legal pad and just a few other odds and ends. Some examples are below (external pockets aren't needed). Typical pad holders are usually more rigid and unzip on three sides. These just unzip on two sides. Or if anyone has a pattern, that would be amazing.

-

Thanks - I’ll check that thread out because that looks exactly what I’m looking for. Do I need to have the gun present to make the holster? It’s for a friend and he (and his gun) live far away. Another reason why I can’t make my own template

-

Looking to make my first holster - made lots of belts, wallets and other items so I think I’m up for the challenge. Not looking to do a wet mold or concealed carry type holster. Looking to do something super classic, maybe western style holster (Mexican loop?) if that makes sense. The gun is a Sig Scorpion 1911.

Any recommendations on a place to look for a template?

-

Yes, guess it is just as easy as typing a knot!

Thank you Hardrada! And Dwight I DO like that idea in this instance of stapling and just using pliers. Didn’t think of that. Two great solutions!

Thank you Hardrada! And Dwight I DO like that idea in this instance of stapling and just using pliers. Didn’t think of that. Two great solutions!

-

How do you Stitch them?

Or rather how do you do the cross stitch? I’m more concerned with how to end the crossed threads, because obviously there’s nothing to back stitch on like a traditional row saddlestitching

-

Or perhaps you just use poly thread and melt the ends?

-

When I make a belt keeper, I normally skive both ends so they overlap. But I’ve also seen it where both ends are cut to precisely bump up against each other or kiss, and are stitched in place, Usually with some type of “X” Stitching. Does anyone know what type of knot to use here to finish this off?

-

Good tips for sizing, but still need a template for the various pieces

-

Would like to try and make a pair of moccasins for wear around the house. Does anyone have a template they've developed that they'd be willing to share? If its size-specific, I'm a 7-8 mends D width. Thanks!

-

Sorry if this should be in the stamping section, but I've often seen leatherwork done with monograms in a nice oval, and border pattern of veiner tooling or camo tooling. But HOW do you get this oval outline and make sure the tooling will perfectly fit around it?

-

If I'm going to stamp, oil, and antique a belt, do I antique the edges? And if so, do I do finish edges before or after antiquing?

-

If I'm stamping a belt, and I want to come in .25" from the edge to start my stamping, I know there are, in theory, a lot of ways I could make this reference line: scroll knife, creaser, wing divider. Each of these would make a line differently, and I wasn't sure if one is preferable.

-

Love Horween English Tan Dublin leather. Looking to make a belt, and want to dye the edges, but not sure which color of Fiebings Pro Dye to use. It seems like either saddle tan or golden brown would work best, but hard to tell from online color charts. Has anyone perfectly matched up this leather with a pro dye color?

-

That sounds better than anything I've come up with before! Good idea! That's why I post here.

-

Is there Any way I can fix this after the fact? I made a belt and wanted holes to be about .6" or .75" apart. Long story, but I miss measured, and as you can see, they are 1" apart, and a hair beyond. Maybe like and 1/16". I know one inch is pretty standard, but I like sub one inch as I feel it offers a more customized fit. It also drives me crazy to know that they aren't even 1" but actually a little more. I also know that using teardrop holes doesn't help things as the holes are longer. Other than leaving it as is, I'm considering trying to squeeze a second teardrop hole in between. Would that look too cluttered? Any chance of a belt hole busting for being too close to another hole? I've also thought of sticking a round hole in between the teardrops. Would that look weird? Any thoughts?

-

Interested in making a belt from cotton webbing or wool webbing (surcingle). The one thing I can’t figure out is how to taper the webbing at the tongue end and buckle end where it meets the leather (see pictures below). Any idea how this is done? As you can see, there is an ever so slight taper, but I’m not certain if the webbing is trimmed or how else this could be done.

-

First, off, I have a paranoia that if any leather edge on any project is not "sealed" in some way, that dirt and moisture will get in from the exposed edges and ruin the item. Is this irrational thinking? To the more specific question, when it comes to Chromexcel, I know burnishing it is very difficult the results marginal. However, due to its characteristics, I think it makes nice casual belts. And in these instances, I usually won't try to burnish the edges. But is there anything that can be done to seal them against dirt/moisture from entering these exposed edges? I've read somewhere here that Allen Edmonds edge dress for leather-soled dress shoes does a nice job, almost like a paint, at both dying and sealing the edges for small Chromexcel leather goods. Would this work for a belt? Any other suggestions?

-

No. I know sew is the strongest, but I like to give the option to switch out Buckles so I use screws

-

Good clarification. I was thinking about center bar Buckles that don’t need a keeper

For those I’ve seen one used. But I use two. On heel bars I’ve seen 2 used.

-

Obviously on a 1" belt or narrower, a single rivet or screw will suffice, but on wider belts 1.25 - 1.5" it seems to me that you'd want to use two rivets/screws, and the first really well-made belt I ever got (and the belt that got me into leathercraft) has 2. But I've seen a lot this wide only use 1. Any method or madness behind these two options? I'd be curious to hear what people say.

Bevel Textured Leather?

in How Do I Do That?

Posted · Report reply

@Danne do you mean you use the high grit paper to sand down the sharp 90 degree edge?