jpt

Members-

Posts

22 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by jpt

-

https://leatherworker.net/forum/topic/80481-all-things-pfaff-145-info-tidbits-maintenance-etc/

-

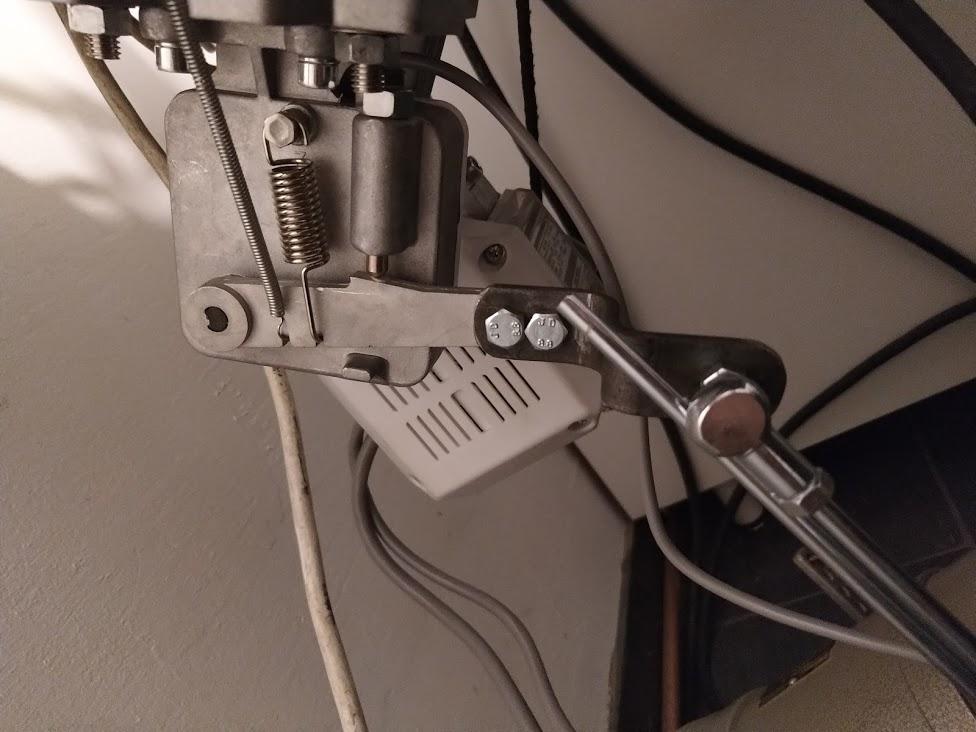

It seemed stupid to buy a whole hook assembly just to get a new guard. As I had a broken saw blade that happened to be of exactly same thickness as the guard, I decided to make a new one. The original was hardened, but I didn't see any reason to harden mine. Furthermore, thin pieces like this can easily distort during hardening. The new guard seems to do its job just fine. While at it I also changed the original 75mm pulley to a 50mm one and added an extension to the control arm to get a bit more travel and thus more control.

-

Thanks for the hints, I will try them the next time I use the machine. Unfortunately, I have the machine in a place that isn't too close to where I live, so it will take some time. Going around the small pin is something I saw in a video on how to thread Pfaff 1245. Now that I looked at the picture on the cover of Pfaff 545 manual, the pin is not used. My machine is H3 variant and uses 134-35 needles.

-

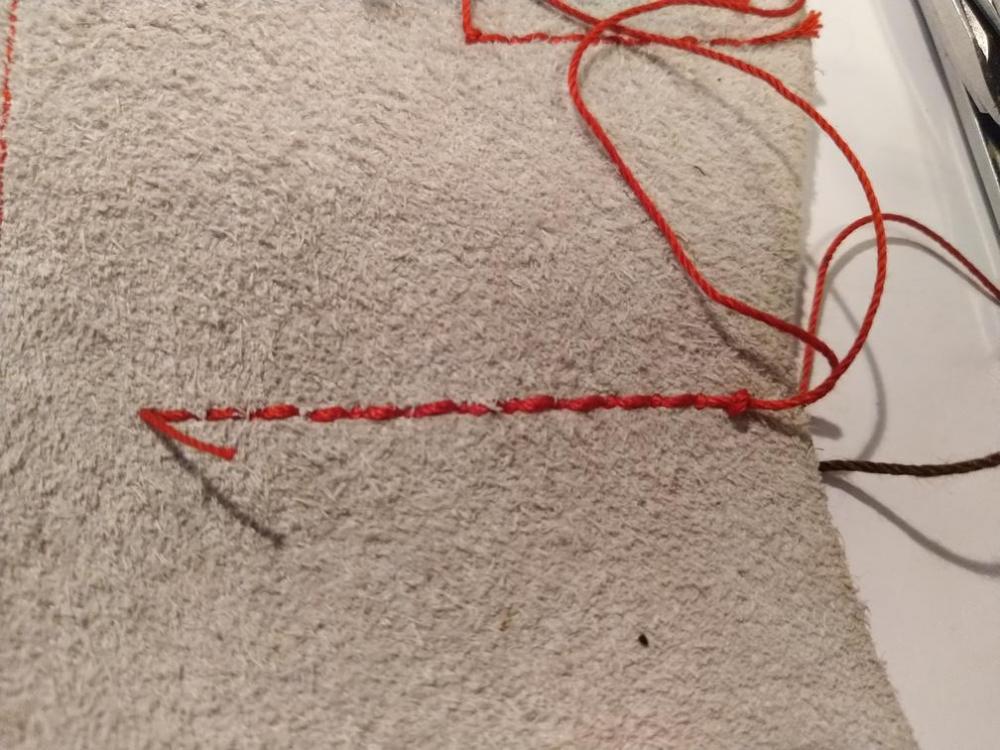

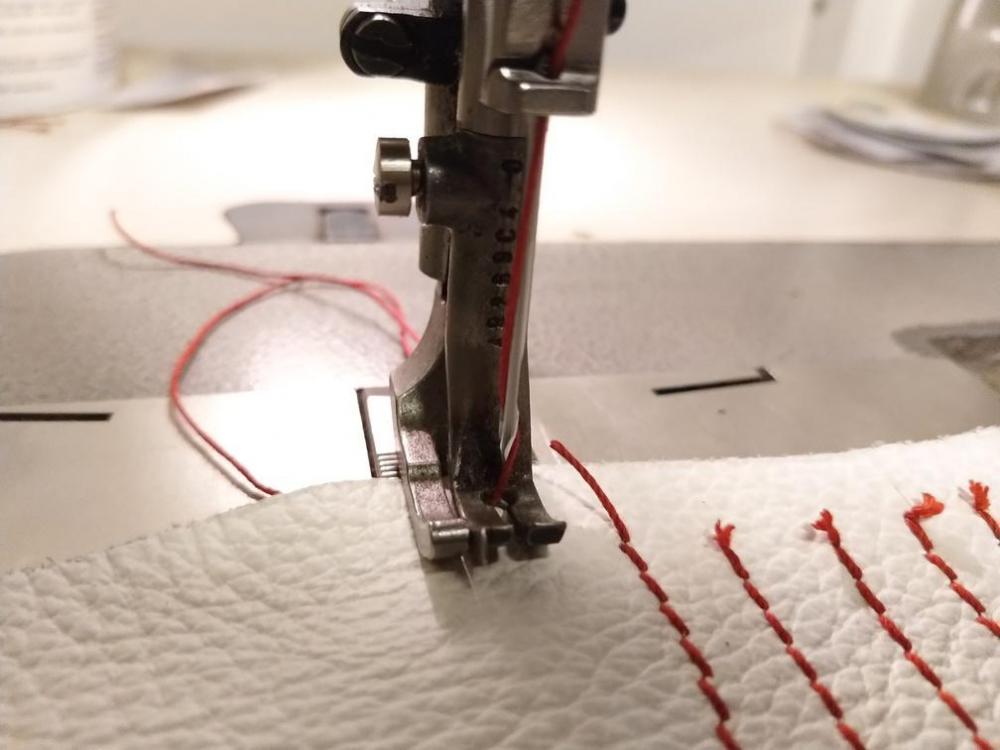

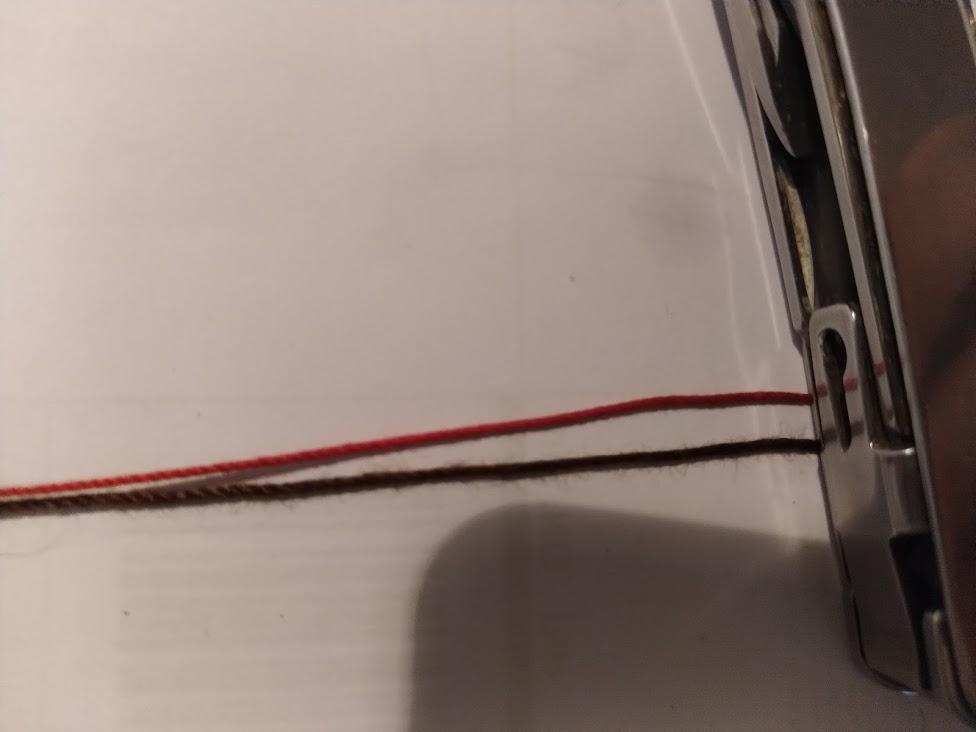

Yesterday I visited a small leather bag factory that has been closed down for some time. The owner, around 80 year old lady, is selling some of the machinery and that's where I bought my Adler 69 some weeks ago. This time I bought various pieces of small hardware for bags and some spools of threads as well. In one corner she had maybe hundred spools of thread with a sticker saying "Amann Dominator 7". I took one of those, and then at home googled that it is cotton thread and the current product name is Amann Mercifil. The size doesn't seem to be Tkt 7 (#415), if I put it next to Gutermann Mara 15 (#207) it actually looks slightly thinner (in the picture Mara is brown). Some weeks ago I also bought a Pfaff 545, and finally today I had some time to play with it. I used the Dominator thread as I wanted to figure out if I should buy more of it (the price is very low). However, I just couldn't figure out the thread tensions. In the end the bottom tension was almost none and the top tension was so high that it was difficult to pull it by hand. Still the top thread got pulled to the bottom of the leather. I used Nm 160 needle (=23 needle size). I also tested Nm 140 needle (22), but it didn't make things any better. To make things worse, it seemed that the top tension varied. If I had set the tension so that it was difficult pull, after sewing a little bit it sometimes was easier to pull. But there was no consistency in this. Have I threaded the machine correctly? What should I do/test next? And if it is not yet obvious, I have very little experience with sewing machines.

-

I received the motors from College Sewing yesterday. It was a fairly easy swap with the old motor using same spacers. Definitely a lot nicer to use than the old clutch motor. I was doing some testing with different speed settings and at some point I hit the reverse and it went all bad then. The needle apparently hit something and got bent badly. A piece from hook assembly got broken as well. To my understanding the timing was right; no skipped stitches or any other problems. So I guess I have pulled the leather in wrong direction which has caused the needle to bend and hit whatever it hit. Another lesson learned: don't try to mimic the pace of much more experienced people on Youtube videos There is an Adler serial number on the broken piece, but I couldn't find anything with that. I will try to TIG weld the piece together. If that fails then the only option is to buy complete hook+base combo, unless someone knows where to get that particular part.

-

I ordered two servos from College Sewing. Hopefully I get them sometime next week.

-

This is good to know. Would recommend one with needle positioner: https://www.college-sewing.co.uk/jk-563a-1-220v-750w-1-hp-servo-motor-with-needle-position.html

-

Thanks. I found the correct pulleys at College Sewing www-pages, but now I'm thinking about getting a servo motor.

-

Actually since posting I've been looking at servo motors. I had a look at the Jack motors that seem to have 13mm shaft, which is a slight problem. I also found another option that has 15mm shaft (I asked the seller): https://www.ebay.co.uk/itm/1HP-750W-ENERDY-SAVER-SERVOMOTOR-FOR-Walking-Foot-Sewing-Machine-Variable-Speed/264426729590?hash=item3d910fb076:g:zEUAAOSwsMZdQBZV

-

I need to get a smaller motor pulley for my Adler 69. The end of shaft is tapered. Ebay is full of sewing machine pulleys but they all seem to be for straight shafts. Does anyone know a source for ones fitting the tapered shafts (I assume that this is some sort of standard taper)? Preferable Europe (or China if the price is right).

-

Quite often when I have bought old machines the previous owners have been quite unaware how to correctly use the machines. These kind of forums have usually been the best sources for information. Now that I don't have to learn everything by trial and error, why can't I leave the foot height to the max all the time?

-

I did read the manual before I got the machine. The manual indeed says how to change the foot height, however, it does not say why to change the foot height. Being a newbie when it comes to sewing machines I did kind of bypassed that piece of information. I just changed the foot height to the max and tried the same seam I had problems with earlier. Now the machine had no problems to climb over it, so problem solved! Earlier on I also tried playing with foot lift pedal, but that didn't go so well; it resulted in loose threads. I'll leave the technique to experienced operators :).

-

I have now had my first sewing machine (Pfaff 193) for a couple of years. To be honest, I have used it very little during that time. So the only logical move to make was to buy two new machines :D. I bought an Adler 69 last Friday and then a Pfaff 545 on Sunday. I haven't played much with the Pfaff yet, but did a little bit of sewing with Adler. As written by others on this forum, it struggles climbing over seams. The feed dog on my machine is completely smooth. Would a toothed feed dog (such as https://www.ebay.co.uk/itm/KH-69-R-Throat-Plate-Feed-Dog-for-Durkopp-Adler-69-Sewing-Machine/292474269634?hash=item4418d32fc2:g:UhoAAOSwGW9an2e7) make a noticeable difference?

-

I received new leather (rolled around a cylinder) last week. No folds and the overall quality of the leather was better than in the first shipment. They even threw in some extra square feet for my trouble. So all is well

-

There is a used Global WF 5555 walking foot machine on sale. Can anyone comment on the quality of Global machines? The machine comes with pneumatic lift. Any ideas if one can still lift the foot manually?

-

I'm attending a course to make a leather jacket. After having owned several leather jacket, I'm aware that there will be some folds after using them. However, those folds will look more natural than the parallel, straight folds in that leather. I'm planning to have a single back piece and any straight lines going across it would look bad. Actually I spoke with the guy again this morning and he will replace the leather for me.

-

I got my first leather order (two skins of reindeer) this week. To my surprise they were folded inside a small box. There are several fold lines going across the skins. I phoned the company and the guy told me to wipe them damp cloth and hang them for a couple of days. You can see some of the lines in the picture. What do you think, can get rid of them, or should I ask them to send me new skins (which they said they can do)?

-

Problem solved. When taking the machine apart for cleaning, I noticed that I can adjust the movement of the lever C (in the picture). No need for filing

-

There is definitely some dirt/gummed oil in the machine as the stitching length is not constant. I'll try to clean it tonight. Hopefully it'll work for the problem I described above. This is a roller feed machine. I don't see/hear anything rubbing the cover plate.

-

Constabulary, thanks for your input. I guess I should have specified that both the bobbin case (the cover with the spring) and the base are the correct parts according the the Pfaff parts manual. Both have the Pfaff name and the part number on them. So I cannot blame the shop, as it seems that the quilty part is Pfaff. I only filed the case so that it fits on top of the base. Neither the thread nor any other moving part touches the filed part. Also the top/cover plate, where the slot is, has the correct part number. So I don't know where the problem is. All I can do now is the study how the mechanism works, and it seems that I have to file a fraction of a millimeter out of the other side of the slot. I just tested the machine and is sewing nicely if I let the top plate to move a bit.

-

A couple of weeks ago I bought a Pfaff 193 post bed machine. It was missing a bobbin case, but luckily there was a used one in a sewing machine shop close by. After getting it I noticed that the bobbin base was broken. I'm a complete novice with sewing machines, so I didn't notice it earlier. I ordered a new one and I got it today. The case and base didn't fit together, but a little bit of filing solved that problem. A bigger problem is that the base doesn't move freely, and that almost jams the whole machine. If you look at the picture, the part A goes into a slot in the top plate. The slot seems to be too narrow. Actually the part B was broken in the old base, so I guess the problem was the same with the old base. I don't know if the top plate has been replaced at some point. Can I just file the slot wider, or would that create some additional problems?