-

Posts

76 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Mizzy

-

This 111g156 is absolutely the best machine I’ve ever used, it ploughs through anything. I have the comprehensive military booklet for repairs if needed but I haven’t had to do anything yet. The 153w103 was a totally different story. Lots of fiddly work like changing the busted timing belt through the flywheel hole, timing the hook-to-needle, and numerous adaptions like removing a welded-on binding attachment. Hacksaw job that one hahaha. Thanks to the amazingly helpful and highly knowledgeable guys on here, and utube, I did it!

-

-

This is the 112g141 twin needle I’m about to start on. The needle bar needs replacing as the presser foot is welded on (?) and I want 1/4 inch spacing instead. One bobbin case opener is broken, and I’m not really sure if the machine works as it should at this stage. But it’s moving freely, albeit with a grating sound on hook rotations. So firstly I’m pulling the hook assembly apart to see if the bearings are shot. I’ve watched how-to clips about it on utube a few times so hopefully I can manage it!

-

-

Yes I know I have both a knee lifter and foot pedal as I can’t figure out yet how to connect the foot control to the back on this 307g2. So it’s there ready, waiting.

-

I’m very interested in your project. I’m about to start fixing up a 112g141, once I’ve finished the current love job - a 96k41 that I painted pink ... with flowers! Oh and I just finished restoring a 307g2, in white, and with a glittery table top. I’ll add pictures now.

-

Female Hinges for a Singer 112w139 Sewing Machine

Mizzy replied to tmitch's topic in Leather Sewing Machines

Hi from Australia I know this is late but it still might help someone. had the same problem with missing female hinge parts so I improvised by cutting and filing a couple of old feed dog covers. Works well! I’ll try to add a picture. -

Take-up lever, got it. Thanks Sark9. I’m on a mountain inland from Pambula on the Far South Coast of NSW, half way between Melbourne and Sydney. I’ve asked around here who fixes machines and there was a guy who travelled from Melbourne a few years back, but otherwise it’s a trip to Queanbeyan near Canberra. Maybe there’s someone retired nearby who would like a cashie?

-

Today I took the timing belt off and started again. Needle bar at highest point and arrow on timing plate aligned with groove on clutch cog. All good. But nothing has changed. If I lived near a repair service I’d pay someone to fix it, but the nearest place is 3 hours away. I’ve read back through all the posts. The one you suggested RockyAussie (thank you) I’ve read several times. Can anyone please suggest a utube clip that focuses on fixing my feed dog problem?

-

Thank you Gottaknow, that gives me something to work on. Now I know what I need to research and learn about. Very much appreciated!

-

Thank you all so much! I really appreciate your advice, I’m struggling here.

-

I’ve been trying to fix up this beautiful old machine myself, including the table, but I’m stuck on a feed dog problem. When I purchased it recently it had a broken timing belt and a binding setup on the cylinder arm. The binding was easy enough to remove with a hacksaw (it was welded on), and the timing belt wasn’t too difficult. I’ve ensured the arrows are lined up on the clutch cog and timing plate. I’ve ordered new presser feet, fed dog and feed dog plate. But in the meantime, I’m trying to figure out why it won’t advance material. To me, it seems that the feed dog does the opposite motions as intended. Can someone please have a look at it in action on utube and suggest how I could fix it please?

-

Anyone familiar with Singer 72W19 industrial?

Mizzy replied to Mizzy's topic in Leather Sewing Machines

Thanks for commenting! I definately don’t need it or want it so I’ll sell it. Do you think it’s worth $100? I have no idea what to put on it. -

Anyone familiar with Singer 72W19 industrial?

Mizzy replied to Mizzy's topic in Leather Sewing Machines

Thank you cowboy, much appreciated. I’ll probably put it on eBay then as I don’t want it. -

Anyone familiar with Singer 72W19 industrial?

Mizzy replied to Mizzy's topic in Leather Sewing Machines

-

Anyone familiar with Singer 72W19 industrial?

Mizzy replied to Mizzy's topic in Leather Sewing Machines

No not yet, good idea! -

Anyone familiar with Singer 72W19 industrial?

Mizzy replied to Mizzy's topic in Leather Sewing Machines

Thank you Wizcrafts, I always enjoy reading your postings. I’ve resized them down from 1.6 mb to 200 kb’s but still can’t upload them. I’ve rebooted the forum and my iPhone, but without success. Other times when I’ve been successful in uploading a picture, it’s usually after multiple attempts, so maybe it’s my server. -

Anyone familiar with Singer 72W19 industrial?

Mizzy replied to Mizzy's topic in Leather Sewing Machines

Thanks cowboy, I’ve seen some on utube and they look quite difficult to use. The previous owner apparently used mine on shoe uppers but I can’t see how. Or why. I think mine hasn’t been altered but I really wouldn’t know. I’d like to upload photos for people to view and comment on, but I can’t. -

Anyone familiar with Singer 72W19 industrial?

Mizzy replied to Mizzy's topic in Leather Sewing Machines

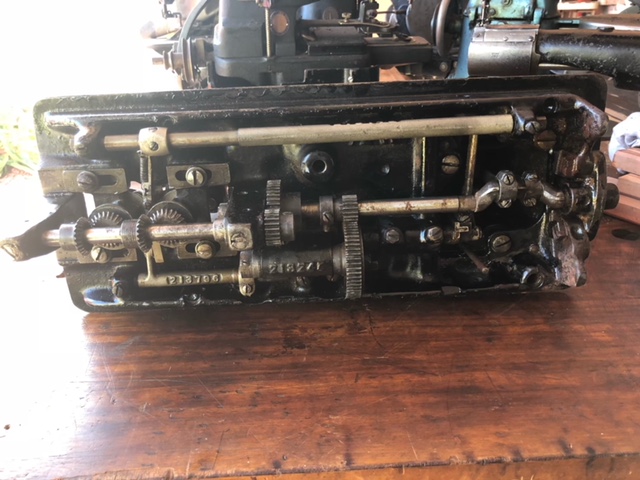

I’ll try to add a few pictures. -

I’ve found the following information on ISMACS, but has anyone used one? “This machine is fitted for two-needle hemstitching on shirt waists, underwear, handkerchiefs, ladies' neckwear, etc. The openings are 1/16 inch and the stitch is known as the over-edge hemstitch, the two hemstitch sides of the opening being overseamed. Attachments can be furnished for use with the machine for automatically guiding and hemming any desired width of material, also for tucking, stitching on lace, plaiting, etc. For ease of operation and for quality and quantity of production, the Singer machines of this class are unequalled. The illustration shows the machine on table and stand equipped with a 1/7 horse power direct-current Diehl motor, enabling the machine to be driven at varying speeds up to 1300 stitches per minute. Its cost in New York, equipped as described, is $157.50 [in 1914]. If furnished on foot treadle stand its cost is $132.50.”

-

Constabulary that’s a good idea, I should make a list so that I know what I’ve got. Hahaha Rocky, I should pay more attention to my sentence structure !

-

Ahhhh finally, it’s letting upload a picture, although it’s cropped a fair bit. That 153w103 is my next project.

-

I already had several industrials plus about that many old Singer domestics going back to 1899 when I found the new lot. The seller was taking them all to the dump, I had to buy them.

-

It won’t let me put any more pics on here at the moment, I may have reached a limit.

-