leatherisfun

-

Posts

134 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by leatherisfun

-

-

-

All sold.

-

Thanks Ken. I think that Mike lost sight of the extras included.

-

-

They are $1610 at the Keystone sewing site. Mine is just over a year old, it isn't a worn out older machine. I have installed a speed reducer and drop down guide.

-

On 5/28/2016 at 4:16 PM, leatherisfun said:

Another 441 clone similar to the Cobra 4, Cowboy 4500. Uses the same 794 needle. It has a smooth needle plate and feed dog. 550 Watt servo motor and speed reducer to go really slow. Has a removable table for doing flat work

Glue pot included along with the feet pictured, extra bobbins, 6 cones of #207 thread, 4 cones of #138 thread.I added two lines of LED's to have more light.

Owned it for a little over a year, selling for $2500.Priced reduced to $2300 Paypal accepted.Located in Longmont, CO. It can be picked up or shipped with you paying the freight.

Call or text 720-201-7991

kirk

-

On 5/28/2016 at 5:48 PM, leatherisfun said:

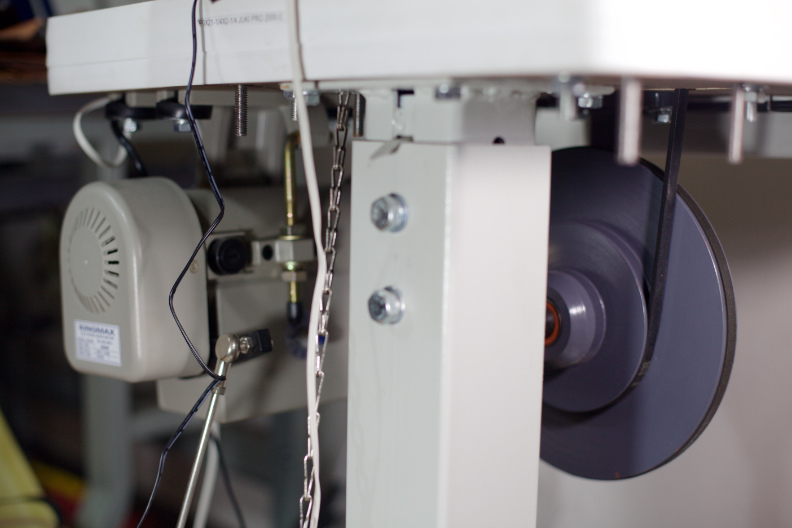

Juki 1541S with speed reducer and drop down edge guide. Sews up to #138 thread and about 6 layers of 5 oz leather.

I'm including left and right zipper feet; binder foot; 1/8, 3/16, 1/4 edge guide feet; 25 bobbins; 15 #18 needles, 100 #20 needles, 13 #22 needles, 49 #23 needles; several cones of thread, #69 and #92.

Selling for $1450, price reduced to $1300

I'm located in Longmont, CO. Local pickup or shipping at your cost.

-

Price reduced to $2300. Can't edit original.

-

A pair of GoldstarTool snap presses for sale. This press also does rivets. With these you can get it right every time, no more using a hammer and hoping for the best.

I also have two sets of dies for snaps, #20 and #24.

Additional dies can be purchased directly from goldstarttool: http://goldstartool.com/home.php

These are normally priced at $60 each.

$45 each for the presses

Both dies for $30

-

Juki 1541S with speed reducer and drop down edge guide. Sews up to #138 thread and about 6 layers of 5 oz leather.

I'm including left and right zipper feet; binder foot; 1/8, 3/16, 1/4 edge guide feet; 25 bobbins; 15 #18 needles, 100 #20 needles, 13 #22 needles, 49 #23 needles; several cones of thread, #69 and #92.

Selling for $1450

I'm located in Longmont, CO. Local pickup or shipping at your cost.

-

-

Another 441 clone similar to the Cobra 4, Cowboy 4500. Uses the same 794 needle. It has a smooth needle plate and feed dog. 550 Watt servo motor and speed reducer to go really slow. Has a removable table for doing flat work

Glue pot included along with the feet pictured, extra bobbins, 6 cones of #207 thread, 4 cones of #138 thread.I added two lines of LED's to have more light.

Owned it for a little over a year, selling for $2500. Paypal accepted.

Located in Longmont, CO. It can be picked up or shipped with you paying the freight.

Call or text 720-201-7991

kirk

-

French plough guage, brass, 15 cm or 5.9 inches. There is a small crack above the blade which doesn't affect the handle or operation.

$275 plus $14 shipping

4" Antique draw guage, brass handle with trigger. Bundled with Leather Wranglers blade.

$120 plus $7 shipping

Cowboy 6" Deluxe Leather skiver/splitter. Bought new less than 6 months ago, only used a few times.

$320 plus $20 shipping

-

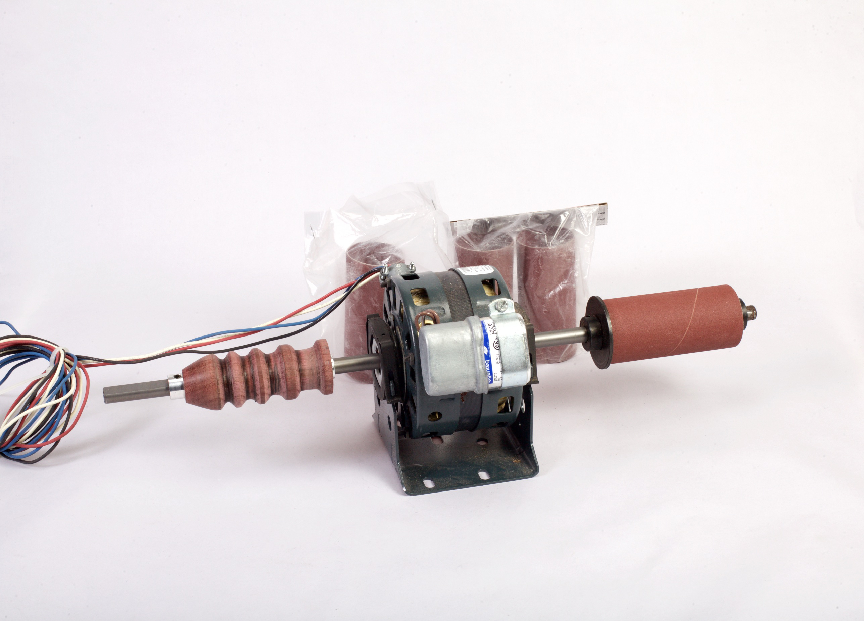

Combination burnisher and sander. This is a two speed motor, with max 1400 rpm at high speed which makes it perfect for efficient burnishing. I made the burnisher myself from a block of Purpleheart wood I brought back from South America. Moving overseas and changing direction, so selling my equipment.

Including the 3 extra sanding sleeves, all 220 grit.

Asking $120

-

This has been mentioned many times, one machine doesn't do it all. A 441 clone will be overkill for sewing soft, thin leather. The needles are much bigger and the smallest thread they use is a #69 size. A 794 #20 needle will leave holes in some thinner leathers. So, the ideal is to have 2 machines if the plan is to sew a range from thin to a few layers of 7oz.

-

The Cobra, Cowboy, Techsew, etc are copies of the Juki 441 and cost a lot less. As a class of machines they share the same needles and attachments are interchangeable. It all comes down to the package that a particular vendor offers, support, shipping cost etc.

That said, it depends on what you plan on sewing. If you are only doing flat items, or close to flat in fabric grade or softer upholstery leather, then a flatbed machine would serve you well but not the one in your post above. The computerized features aren't necessary for leatherwork. The non-computerized version of the same machine would save you some money.

The 441 class of machines are good for sewing multiple layers of stiffer leather like veg tan, chrome tan, etc and products both flat and curved. They will easily punch through several layers of greater than 7oz of whatever you choose.

Given your space limitations, you would need a custom, reduced size table. Tables which come with flatbed machines are much bigger. Standard table size is 119.38 cm long by 53.9 cm wide approximately.

-

My vote for light stuff. The machine you chose is primarily for fabric. Like dikman said, simple is better, easier to maintain. http://www.chinahiled.com/enproductslist.asp?id=555

For heavy leather don't know what the price difference would be, but the HL-441 is a great alternative

-

DXF file of my improvised press which is in the main gallery. If you have any questions, just ask.

-

Needle/thread is way too big. You can still get the effect using smaller thread. Try 69 thread with a #20 or #21 needle. I found using #46 thread with 2oz veg tan glued to lambskin works great. I tried thicker thread and it was a nightmare getting the stitches to look right. One tip I picked up there was to decrease the stitch length, doing that helped a lot.

-

If you are making a 90 degree turn, leave the needle buried, life the foot, turn piece. You might have to turn wheel by hand to get it into the position you need without overshooting. Otherwise the above applies.

-

Go as slow as you can and try to maintain the same speed while going around the turn. Guide the piece, don't fight it or force it. Practice is the key to getting better at such tasks. Make good work of that scrap pile.

-

Simply put, 138 is too big for what you are trying to sew. Try 69, which will also take some work to get the tension figured out. On material that thin, 46 has worked better for me, which I did on my flatbed.

-

Read the posts in this thread: http://leatherworker.net/forum/index.php?showtopic=25239

-

The general rule is to replace after every 8 hrs of use. Using the needle until it breaks just isn't worth it to me. Things like fraying/breaking thread, skipped stitches, etc can happen when the needle is dull.

Scharf-fix 2000 for sale

in Old/Sold

Posted

Longmont, CO