chainftw

-

Content Count

107 -

Joined

-

Last visited

Posts posted by chainftw

-

-

No, not what I’m looking for but I’ll keep you in mind if I need a stamp

-

1 hour ago, RockyAussie said:No... I’ll send pic ..

-

-

Look closely at them and you will see .

-

-

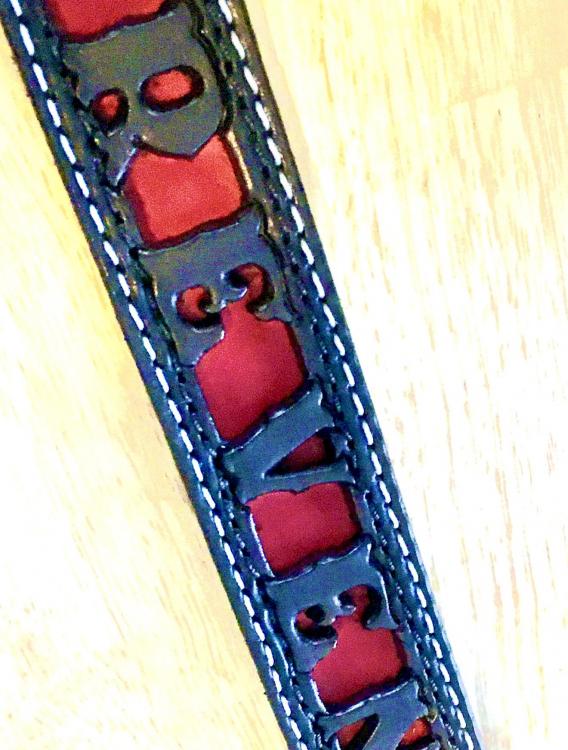

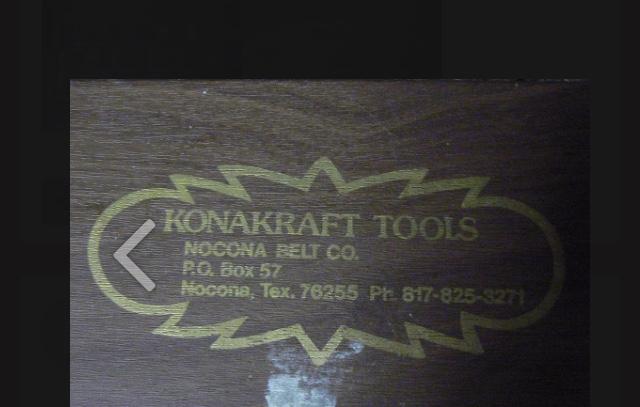

Looking for a filigree letter stamp set . Made by nocona Or anyone else . It cuts out spaces between letters as it stamps .

I’m ready and willing!!! Thanks -

Anyone know who made those block letter stamps that also cut the space between the letters ? I know there not made Anymore but I’d love to find a set !!

Thanks!

-

-

-

Hopefully 2 more weeks , the shafts where machined the wrong size!!!

-

17 minutes ago, bullmoosepaddles said:I can not market. but may be interested in buying one for myself. If that would work for you.

Ok thanks .

-

16 minutes ago, bullmoosepaddles said:Pictures would help.

I do realize that but it’s in design .Should be ready to Go in about two weeks . just wanted to see if I should possibly market it since I made and designed this for myself , because $600 for one seems ridiculous.

-

Hey everyone ,

Just wanted to see what everybody’s thoughts were on a $200 belt embosser that you could take the embossing rolls that anybody makes and put on this machine . It’s very very simple to use and all steel construction with heavy duty bearings and adjustable height for different thicknesses of leather. Hand crank , and Made in the USA by me..

.Do you think there Would be a market for it , Again for about $200 .

thanksPaul

-

You, my friend.....

Are The Man !!!!

Thanks, it worked Perfect !

Paul

-

Hey All,

I'm new to the Sewing machine world . I just got a Techsew 5100 SE, used but in great shape ....but....

The backstitch will not line up with the holes on the forward stitch . The stitches are farther apart then the forward stitches .

I'm pretty good with working on stuff but I have no manual to tell me anything so I have been learning on line and this site, so thank you for all

the help I have been given thus far by many on here !

I searched this but can't seem to find any info ...

Thanks !!!!

Paul

-

SOLD...

-

1 hour ago, RockyAussie said:Closest machine for the job that I can think of would be the Techsew 2600- https://www.techsew.com/us/techsew-2600-narrow-cylinder-leather-industrial-sewing-machine.html

That would get you about 7mm in from the edge and thread up to 138. Some bigger diameter cylinders will get close as well with some modifications but I like the small diameter for other bags and stuff myself. On the end I decided to go with an end cap to fill the hole as shown in the following pictures. This is easier to do if you have a 3d printer as you can just print the diameter and depth of cap you want to cover instead of sanding down a eva rubber as I did in these pictures.

This one is the finished bag

Looking inside and note the gusset end position

The stitch on the outside goes into the lining only and a leather filler cap is glued and pushed into the gap first

The end cap is made with design stitched on then attached to a eva foam to fit firmly into place. This piece was the fake croc test piece.

This shows the back of the plug ready to glue up and push into place.

All the thread in this case is 138 (20M)

Note: I don't believe a shoe patcher will give you the quality of stitching that you would want with this type of job myself.

If you do go with the Techsew make sure it is the type with the oscillating dog foot and not one set up for binding.

Awesome man !

-

On 9/13/2020 at 4:05 PM, Matt S said:Many common cylinder arm machines have a larger distance from the end of the cylinder arm cap to the needle than you might desire for this job. You're right, it's not a frequently quoted specification, but one that many leatherworkers would like to know. Often the distance is around 6mm (1/4") or more, especially on walking foot machines. Certain models and subclasses have been built and modified to reduce this but they aren't very common and usually have a short stitch length.

I've got around it sewing the bottoms onto cups etc. using a regular cylinder arm machine by making the bottom a little deeper to accommodate but I don't think that that's a great solution. I think that Wiz' suggestion of a patcher is an excellent one.Thanks !!

-

53 minutes ago, Wizcrafts said:I've sewn end caps on dice cups using a shoe patcher. They usually allow you to get close to 1/8 to 3/16 inch from the edge to the needle. There is no need for an edge guide as long as your edge is even (e.g., sanded and slicked outer edge). The nose of the cylinder arm will stop the shaped item from going any farther in.

I recommend a large bobbin model so you can use #138 or #207 thread, depending on the total thickness to be sewn. Most shoe patchers can sew between 1/4 and 5/16 inch compressed leather.

Thanks ! Much appreciated !!

-

Here is one of may bags. What I would like to do is use a machine instead of hand stitching since my fingers are shot.

Looking at cylinder machine but don't know if I can get the stitch close enough to the inside edge to look right on the end cap piece(hope that makes sense) .Totally new at machine stuff so if it's a dumb question bare with me ...

The cylinder would be placed in side the end cap from the outside(lol) to stitch to the bag...

Thanks

-

I like that machine ! You ever sew light weight stuff on it ? I here it's great for heavy stuff but not so great and under 6oz..

Why are you selling it??

I'm in Myrtle Beach .

Paul

-

Hey just curious what is the thickest thread you can use for this machine??

Thanks

-

1 hour ago, Northmount said:IP address indicates he could be near Leesville, South Carolina, 29070

Looks like he doesn't check in very often, last was Sep 1.

Tom

LOL, Thanks Tom !!!

-

5 hours ago, chainftw said:Hey, How much is it and where are you in SC??

Thanks,

Paul

Sorry I see the price , where in SC are you ?

Filigree block letters

in Stamping

Posted · Report reply