-

Posts

14 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by 227Crafting

-

Looks like you ended up in the same boat I did. Not enough time to do much leather work with a kid and work. Good to see you got some use out of it and it is in good condition.

-

I can try, but you will need to be more specific as to what you want to know about this machine.

-

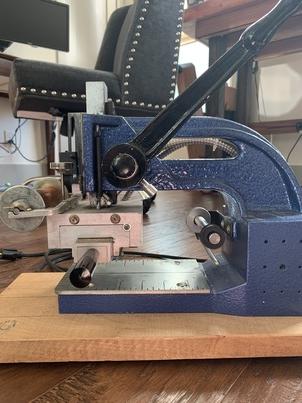

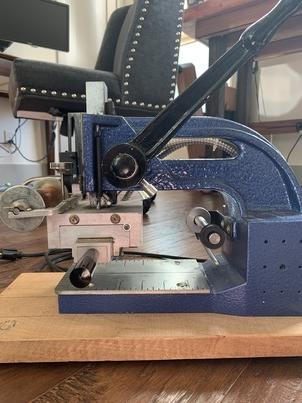

I have a Jason System foil stamping/heat embossing machine. The price on this is 280 + shipping. I am located in Austin TX I have used this a hand full of times. I've decided to sell this off and go with a different machine that will fit my needs better.

-

-

I think the pole part of this thing is pretty solid. With that being said I've not taken it apart to see if it is a solid piece or hollow. If it is solid it could be drilled out and re-threaded to allow for a larger bolt to go up into it. I do have a Jason System hot foil stamping machine that I have for sale. I'm selling it for 285 + shipping.

-

It flexes at the base where the two attached. I feel like the springs would create a situation were there would be a lack of pressure being created due to the springs compressing.

-

I have one and its a decent machine. There are two things about it that can cause issues. This is the first and really one gripe I have about it. The shaft that attaches to the base plate and holds which holds the rest of the machine will flex. What I mean by this is, when you exert a lot of pressure down onto leather that requires a good amount of pressure to leave a deep'ish impression the shaft will flex. What that does is cause your stamp / makers mark to leave an uneven impression. I found this to happen more with thicker veg tan and bridle leathers. The minor issue I have, and this was due to me not thinking this purchase through fully is, depending on the size of your stamps or makers mark you will need to get the correct heat plate for you needs. If you are only doing to use one stamp then get one that has a small heat plate. I have one that is 3.5" x 3.5". It makes it really though to get my makers mark lined up to be parallel, plus it also makes it difficult to position your leather correctly as well, especially when its hot. If you are going to use thin leathers, 2 to 4 oz thick and or chrome tanned it will work good. In all honesty you don't need to make a deep impression with this machine, its not really used for it. It will do great for getting the foil stamp on the surface of the leather. I hope this info helps.

-

I have both, a bell skiver and a Scharf. I picked up the Scharf before the bell skiver and found it to server a decent purpose for skiving down small areas. I've also found it to do very well on thinner leathers that also stretch, such as goat skin. If you can't afford a bell skiver and have had issues with hand skiving picking up a Scharf is a good option. With that being said I would advise to stick with getting a genuine article Scharf. I found mine on Amazon for a little over 200, it was on sale I think. But still it is a good skiver that will help you to increase your production times and in crease accuracy. Like most I've ruined a project by messing up on hand skiving. Any who, that is my two cents.

-

Depending on your budget you should look at Kwick print machine. They are good machines, there are some on Amazon that come from China that might do the trick for you. I have a Zonepack ZS-80 machine. Its ok and does good when you used to stamping using heat activated foil. Issue I have with it is if you try to exert a lot of pressure the pressure will not be distributed evenly across the leather. This happens because the post that the press part is attached to will flex. You can look on Etsy, Ebay and Amazon for these things.

-

I'm interested in what you have. Would you be able to setup a time to discuss this over a phone call? I'd like to get more information.

-

Sorry this machine has been sold.

-

Thank you. I'm sorry I don't do any financing on the count I'm selling it out right.

-

Hello fellow crafters, I've decided to sell my Techsew 2700 pro walking foot sewing machine. It is just over a year old by 3 months. It has been well taken care of, regular oiling, kept inside my house in a very clean shop. Two months ago I installed a speed reducer so it now has that. As for the amount of usage this machine has seen its less than 8 or 10 hours of total usage during the 15 months I've owned it. You will be getting all the standard add-ons that come with this Pro machine. Servo motor, fold-down guide with two types of guide feet, three different walking feet (see below pictures), this machine also has a laser light guide as well. I also purchased the flat top add on. This allows you to turn this cylinder-arm machine into a flat top machine. You will also get all the needles, bobbins, and newly purchased thread that I've picked up. As for where I am located, I live in the Austin Texas area of this massive state. I'd like to find a Texas-based maker to sell this to so I don't have to deal with shipping. My sale price is $2,000.00, I'm firm on this price since it is brand new, well taken care of and comes with some extras. Pictures of the machine can be found here. https://imgur.com/a/MryT9VG Send me a DM to discuss. Thank you.

-

I am in the market for a sewing machine to increase my production of some items. I've found a Juki Industrial LU-563 in my area for what looks like a good price. I mainly make wallets, watch straps and belts. Can anyone speak to the max thickness this model can sew through? Right now I am hand sewing through at a max of 8 to 10oz veg tan leather. Would this model have an easy time working with garment leather and chrome tan leather? I would like to make totes using chrome tan leather at a thickness of 4oz doubled at the seams. Thank you