ryanww

Members-

Posts

16 -

Joined

-

Last visited

Recent Profile Visitors

1,652 profile views

ryanww's Achievements

Member (2/4)

-

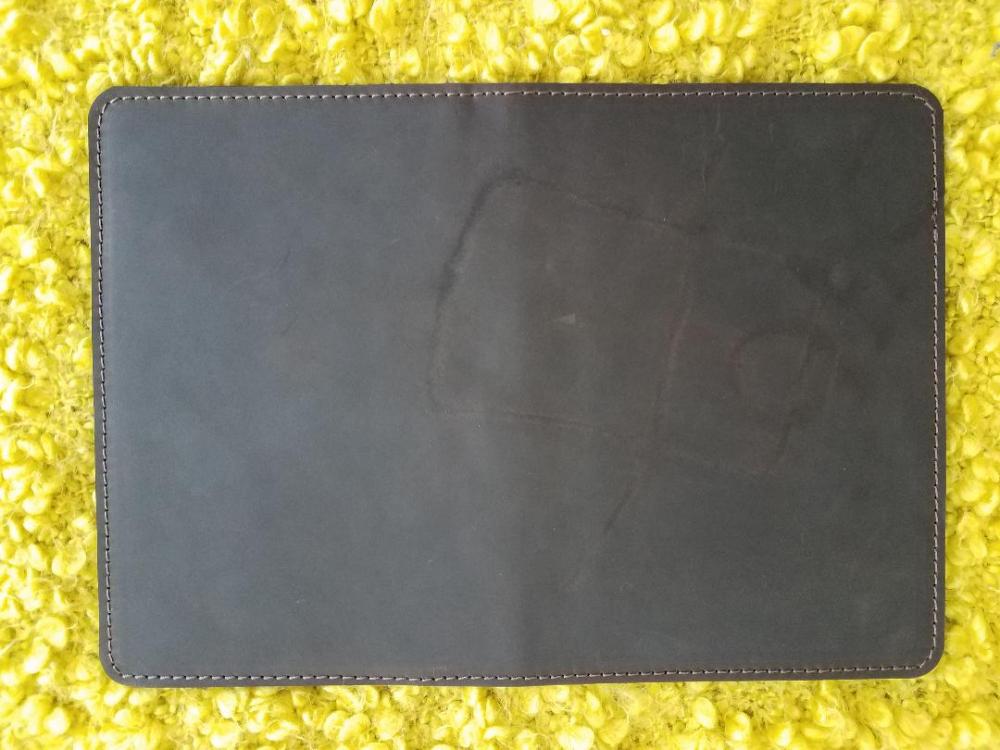

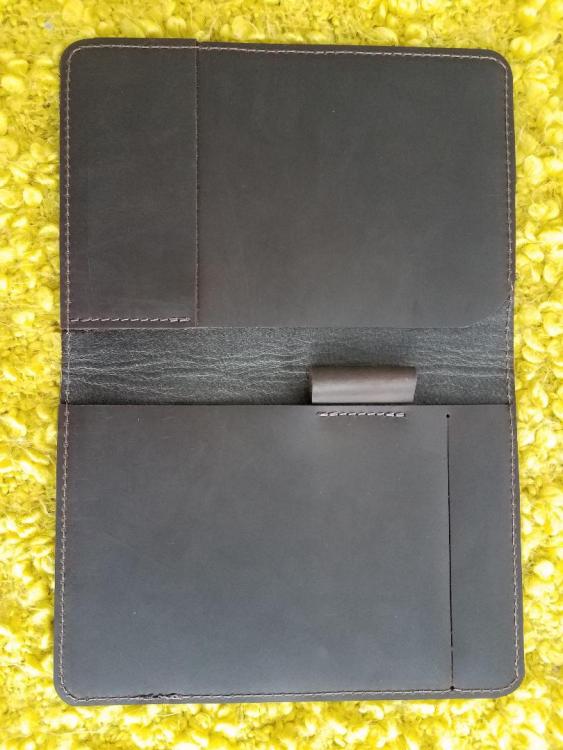

My first attempt at a mini portfolio

ryanww replied to ryanww's topic in Books, Journals and Photo Albums

It does not burnish at all. I don't mind the rough looking edges, but the visible lining bothers me a bit. I'll look into the dyes you mentioned. Thanks -

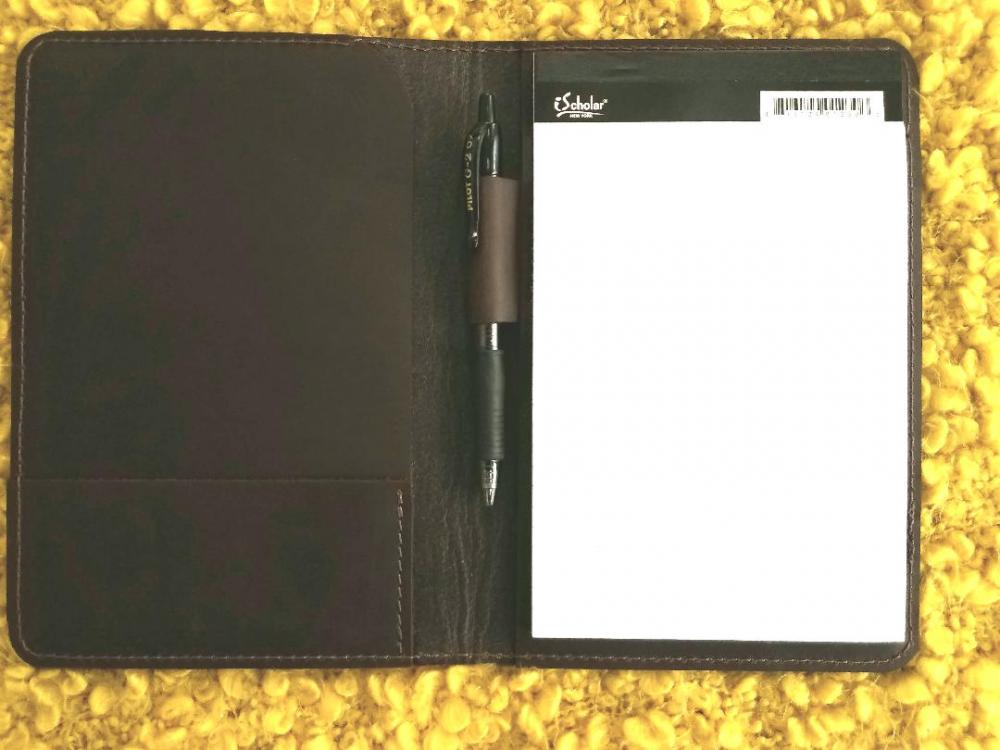

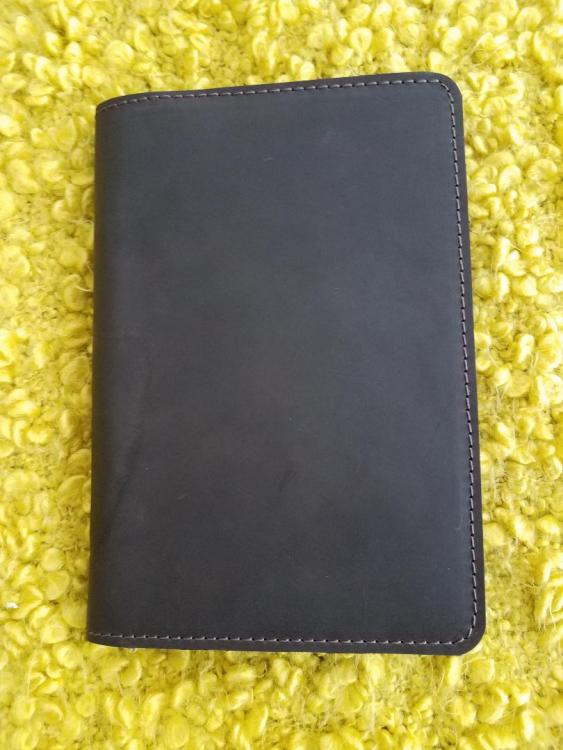

I'd like to make a full size one, but thought I'd start small in case I screwed something up. Cover is some sort of oil tanned leather completely lined with pig skin. I sandwiched pieces of plastic quilting templates between the lining and the cover to add stiffness. The plastic pieces are set in 1/4 inch from the edges, just inside the stitch line. The pockets are made from the same leather as the outer cover. I did not finish the edges at all and the pig skin lining material is visible between the two layers. I may try to dye the edges, but not sure yet, advice is welcome. I machine stitched with Pfaff 1245 using 138 polyester thread. There is one area of mis stitching and I know what caused it. I won't give it away though, you'll have to look for it. Comments, critiques welcome. Ryan

-

I've made a few journal covers with internal pockets and I've used thinner leather for the pockets and thicker for the cover itself. I have some 4-5 oz oil tanned leather that I'd like to use to make a portfolio and journal cover. The leather is probably too thick to use for the internal pockets, or is it? Do you skive the pocket pieces down? I only have a small skiver and haven't done large flat pieces before. Is there a different technique to make these pockets? Thanks for your help.

-

I think the sewing machine belts are size 3L, but not 100% sure. Technically I think you could mount the reducer on top of the table if you don't have room below, but you have to watch the position if you want to be able to tip your machine. It's hard to guess the belt length you will need until everything is assembled.

-

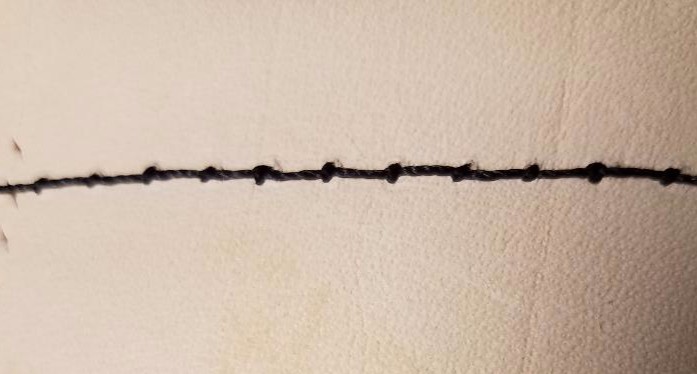

Thanks to everyone for the help! The two most effective suggestions were to use a larger needle and to try thicker leather. Moving to a size #23 needle made a huge improvement. Now making top tension adjustments actually makes a noticable change in the stitch. I think I have a good handle on things now but I'm sure I'll have a million questions as I continue to learn. Thanks again!

-

On my list! Thanks

-

I'm not there yet, but working on it! I'm really hoping to be able to use 138 on top and bottom because I like the thicker thread look.

-

I'm a little confused, are you saying it would be easier for the knot to pull up with thicker material?

-

I've noticed some improvement with maxing the downward pressure but not much. I ordered some larger needles, but they have not arrived yet. I've tried a lot of different leathers so far. 2-3 oz veg tan, 4oz upholstery, 4 oz oil tanned. I've noticed with the softer leathers it does pull the knot up a little bit more, but not very much. What is a rough guide for top tension? I have it so tight right now I can hardly pull the thread through the machine with the presser foot down. After stitching the pieces tend to cup a little toward the top because the stitches are so tight. I know that's too much tension.

-

This is entirely possible that the pressure is too light. I will try to increase the pressure. Good tip, thanks! I'm not sure where the idea comes from to go around the post. The manual clearly shows not to go around the post. To be sure I've tried it both ways without any noticeable difference.

-

I do have a wrap around the top guide post. I will try this. You may be on to something here. From my reading I figured size #22 with 138 thread was a safe bet. The hole punched by the needle is more of a slit than a hole. I don't currently have any other needle sizes or designs so I will have to get some.

-

I have not tried it with any other thread. Before I got it, it was sewing nicely with #69 thread using a different needle through synthetic fabric and webbing. I will check the discs for wear, but the issue is not irregular, it's regularly off

-

-

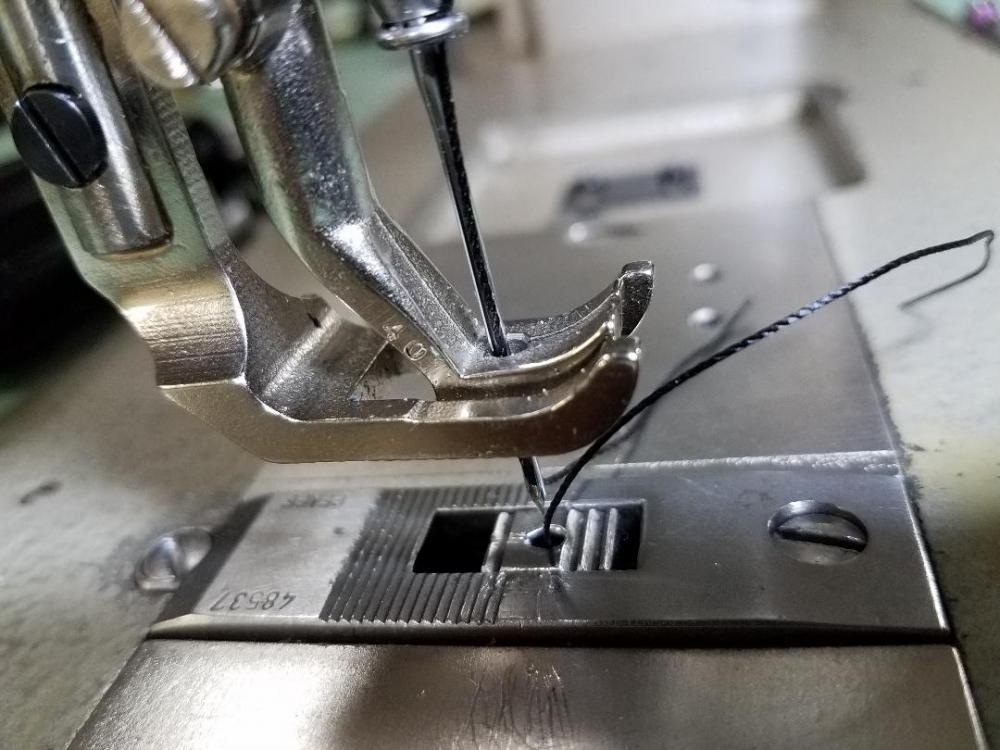

I have a new to me Pfaff 1245-706/48 CLPMN. I'm brand new to industrial sewing machines. I found a copy of the service manual, adjustment manual, and owners manual thanks to some older threads on this site. I still have a few questions. A few simple adjustment questions then some more complicated stitching question. I'll try to provide as much information as possible but if I'm missing something or you need more pictures just ask. I'm using 138 bonded nylon thread and a 190 LR size 22 needle sewing through various leathers, 2-3oz veg tan, 3-4 oz upolstry leather, etc. 1) The presser foot height adjustment screws slipped a bit and I've readjusted the height, but my question is should the needle plate be the bottom stop for the presser foot, or is there a metal on metal stop somewhere else? Before I adjusted it the hinge would bottom out on the frame of the machine and the presser foot would not sit on the needle plate. I'll show in a picture. 2) The manual states that the vibrating foot and the needle point should arrive at the needle plate at the same time when set to the longest stitch length. Mine is very close, probably within 1/16 - 3/32" , but everything seems to feed nicely and be timed together. Is this a real critical adjustment? If I adjust the vibrating foot I'll have to adjust the feed dogs too, because those two seem to be in time really nice together. 3) I'm having a few stitching issues. At first the machine was skipping a few stitches. Someone had adjusted the needle height to be be in approximately the right location when the hook spun around, but I re-evaluated the timing and it was off by about 60 degrees according to the service manual. I successfully re-timed it and now it never misses. However I'm having what looks like tension issues. The stitches look like not enough top tension or too much bobbin tension. I've gone through the whole range of tension on needle thread from barely able to pull the thread through the disc to fairly loose. I've also gone through the full range of bobbin tension and it is currently very loose. Adjusting the needle thread tension does change the appearance of the top a bit, but it's still not pulling the lock up from the bottom. I'm 99.9% sure everything is threaded correctly. I'll show some pictures of the stitching. Thank you in advance for your help! Ryan Top Bottom

-

Thank you. I have looked at their website. I was hoping to find some dies at a discounted price vs new.

.thumb.jpg.1dc6c44a5e13f4c87731e5213a8ab419.jpg)

.thumb.jpg.e75054e698de69cfb12e32fc21614a9e.jpg)

.thumb.jpg.031bd98d7e8515ec90477db7eeb095ba.jpg)