Parfektionisto

Members-

Posts

100 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Parfektionisto

-

Hahaha, I like the way you put it. That’s why I said this is the cheapest I had found so far. Most probably I could get it slightly cheaper. Last year I almost bought a 335-H3 for $635, but glad I didn’t jump into it as I was hopping that the price will drop, but guess my patience pays off now. I bought a few machines last year, all thanks to Covid19, as a few local businesses wind up. Bought 2 Singer 211, and a 6 threads Yamato overlocker.

-

Thanks guys for the infos and personal opinions. Actually I sew more duck canvas than leather and it can go as thick as a few layers of 24oz. This machine is selling at $460, the cheapest I have came across so far. I probably could negotiate for a lower price, but I need to find the time to go test out the machine first. Tony

-

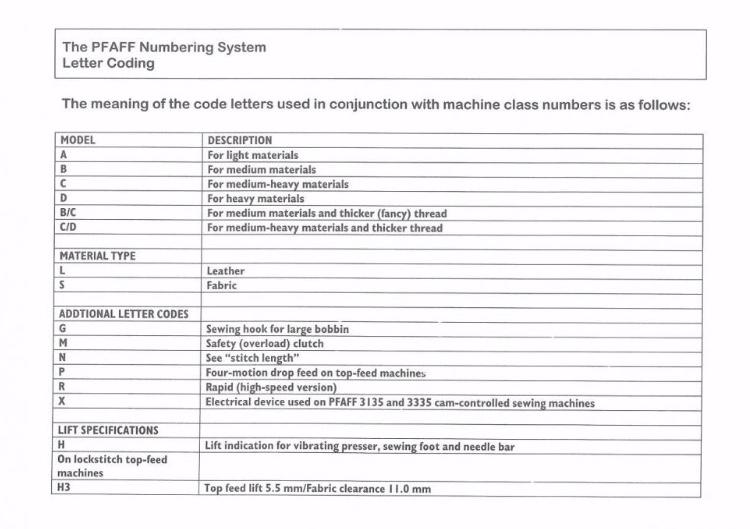

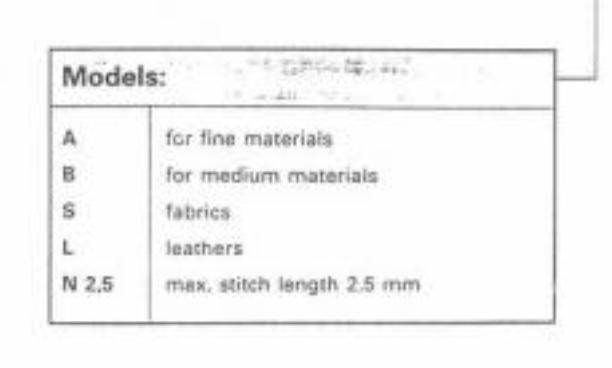

Hi guys, Recently I came across this Pfaff 335 with a subclass I couldn’t find any info online. It doesn’t have the H2 or H3 alphabet and I also can’t find any infos on BL. Could anyone who knows anything about this particular subclass pls provide me some infos, like its capabilities, and what kind of leather thickness will it sew? Thanks. Tony

-

Restoring sewing machine table

Parfektionisto replied to Parfektionisto's topic in Leather Sewing Machines

Awe your technical skill set and knowledge is always helpful and produce stunning result. -

Restoring sewing machine table

Parfektionisto replied to Parfektionisto's topic in Leather Sewing Machines

Nice and neat, another more decades to go:) -

Restoring sewing machine table

Parfektionisto replied to Parfektionisto's topic in Leather Sewing Machines

That’s great. You seems to be good in metal work. -

Restoring sewing machine table

Parfektionisto replied to Parfektionisto's topic in Leather Sewing Machines

Nice and great ideas, thanks for sharing. -

Restoring sewing machine table

Parfektionisto replied to Parfektionisto's topic in Leather Sewing Machines

Thanks for the advice, I bought the castor wheels from a sewing machine dealer. They do look sturdy to me, hold it works well. -

Hi, Beside making new tables, did anyone restore their sewing machine tables? This is my first time restoring a machine table, did some research online before getting into the work. The old laminate on the table was hindering my work as it tore the canvas I was sewing a couple of times , so I have no choice but to find the time to restore it. I also added castor rollers, so that I can move the sewing machine around. I hope to restore the paint on the machine as well, but I must really find the time for it. Pls share pics of your restored tables too. Tony

-

Need help with Singer 211U566A

Parfektionisto replied to Parfektionisto's topic in Leather Sewing Machines

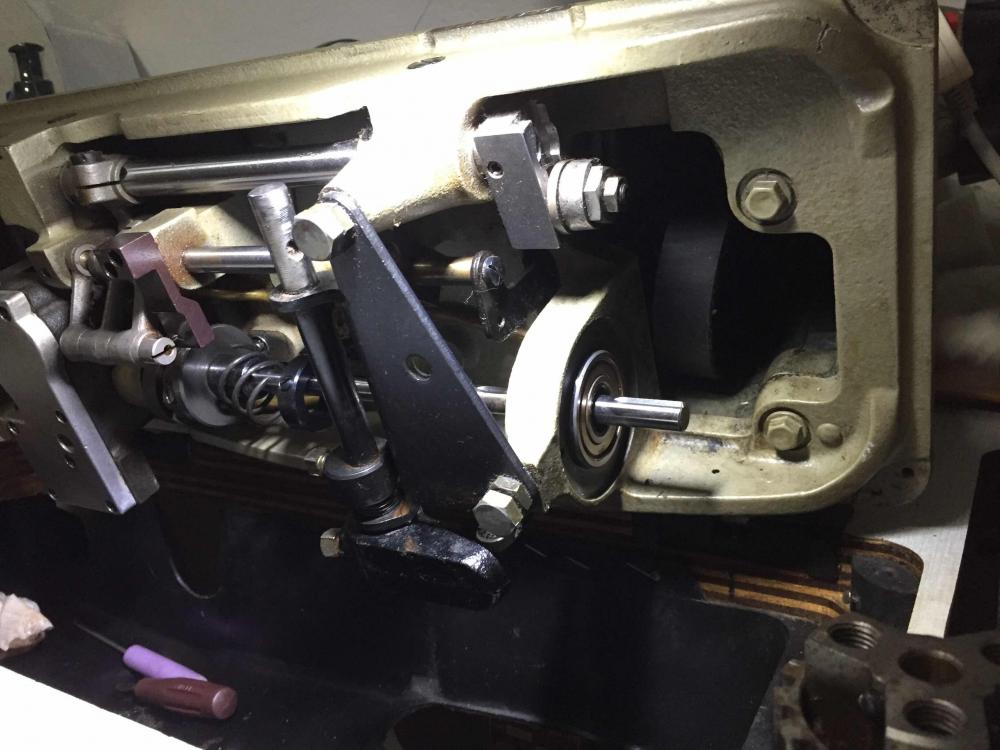

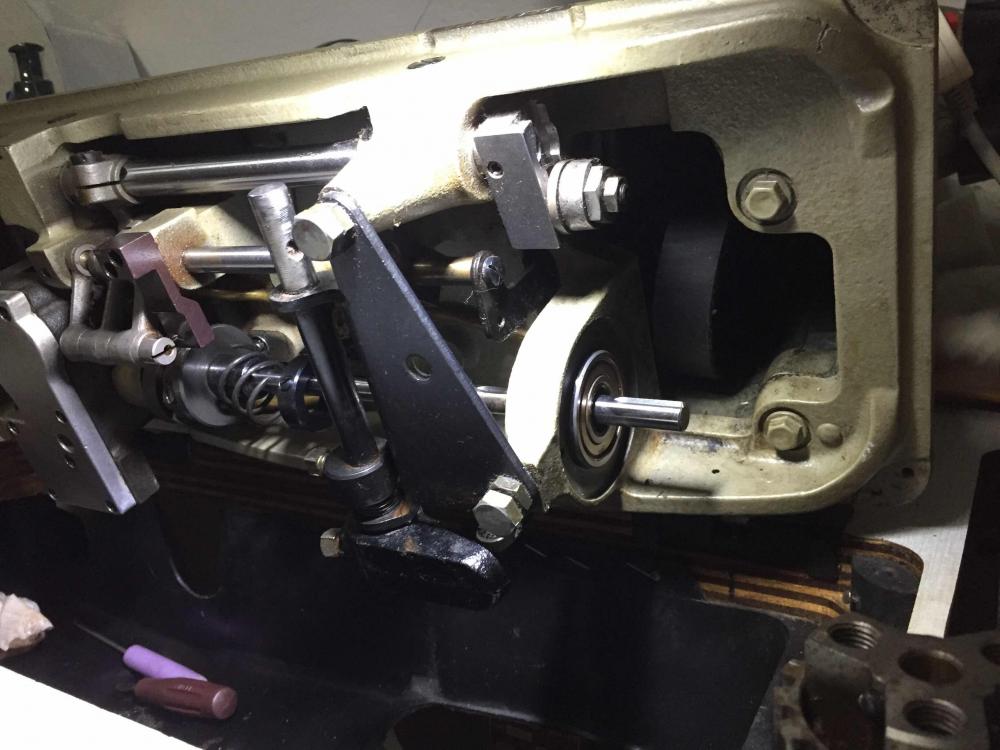

There are couple of issues, the main issue be it the feed driving flange and the feed driving eccentric adjusting disk alignment was off, as I mentioned earlier I notice the screws on the flange were loose. Then I actually created more problem by removing the clutch belt pulley and didn’t put it back in the right alignment. This repairman is very patience and professional. He took his time and patiently put back the eccentric disk and spring which I didn’t know how to put it back after dismantling it and start inspecting the rest of the issues patiently. It took him around 3 hours to fine tune all the alignments. I’m so grateful for that. -

Need help with Singer 211U566A

Parfektionisto replied to Parfektionisto's topic in Leather Sewing Machines

Hi guys, Thanks for all the help and advices, really appreciate it. Anyway, I found a local repairman and he managed to revive the machine back to working condition. Problem resolved . -

Need help with Singer 211U566A

Parfektionisto replied to Parfektionisto's topic in Leather Sewing Machines

Still can’t figure out how to put the spring and disk back in place. Might need an adjustable clamp or some sort of plier to compressed it. -

Need help with Singer 211U566A

Parfektionisto replied to Parfektionisto's topic in Leather Sewing Machines

Yes the pin is intact. The spring is too strong to be compressed by the plier -

Need help with Singer 211U566A

Parfektionisto replied to Parfektionisto's topic in Leather Sewing Machines

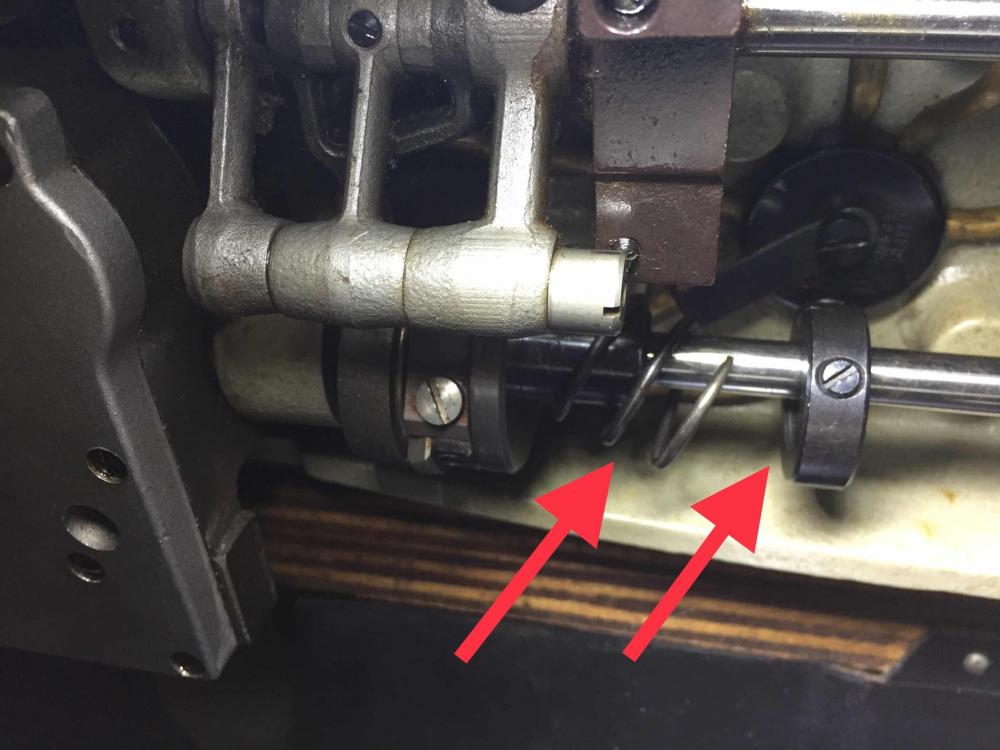

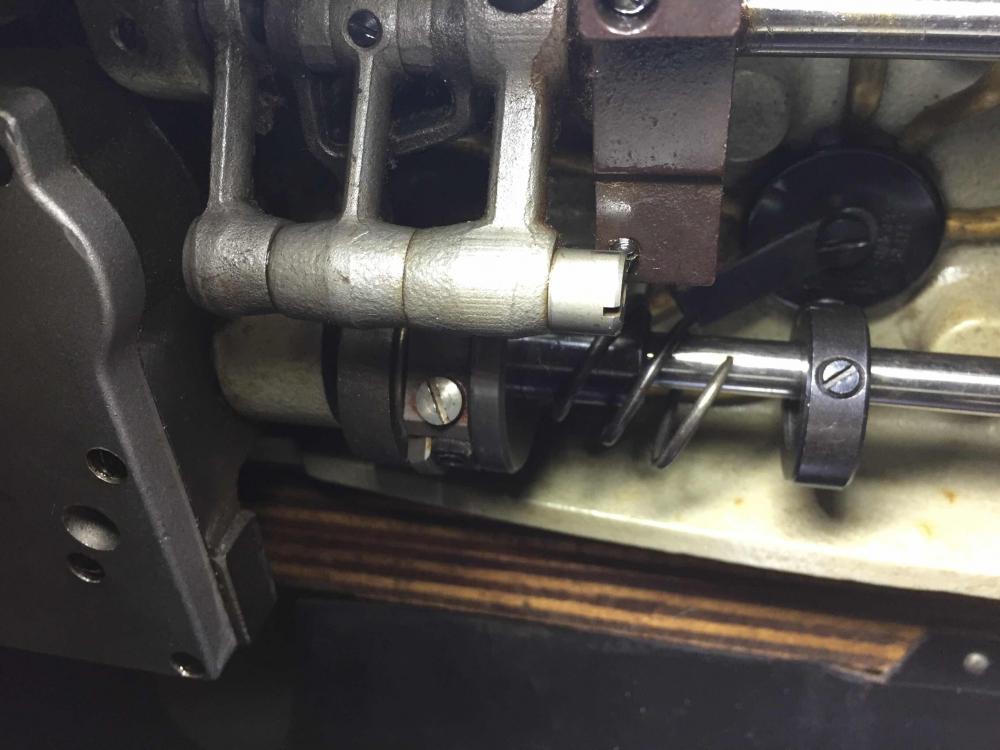

My concern now is to put back the eccentric disk and the spring, but I can’t figure out how to put it back in place, that’s why I’m thinking if I should remove the shaft. Do you know what I mean? Any idea how can I put the eccentric disk and spring bk in place? See what I mean in the pic below. -

Need help with Singer 211U566A

Parfektionisto replied to Parfektionisto's topic in Leather Sewing Machines

I was using a hammer trying to push the shaft out, but that’s the furthers it goes as what you see in the pic, I’m afraid if I hit harder I might damage the tip of the shaft. -

Need help with Singer 211U566A

Parfektionisto replied to Parfektionisto's topic in Leather Sewing Machines

Yes the pin is intact, at least I have it removed, check and put it back in place. It seems like the problem could be the screw not tighten on the feed driving flange. Anyway, now I’m having the issue of putting the eccentric spring and collar back in place. It seems like I need to remove the shaft, but I’m unable to it. Could you advice me how to do it? -

Need help with Singer 211U566A

Parfektionisto replied to Parfektionisto's topic in Leather Sewing Machines

I had removed the eccentric adjusting disc spring collar as seen in the pic below, and I realise some of the screw on the feed driving flange is not tighten, so I tighten them. After tightening I tried to adjust the stitch length again, and I was able to adjust the stitch length longer, but the hand wheel still doesn’t stop when I turn. Now I’m trying to figure out how to put back the eccentric spring with the collar? I tried to remove the safety clutch belt pulley so that I can remove the hook driving shaft, but I’m stuck and couldn’t figure out how to remove the shaft. Could someone advice me how to remove the shaft or how can I put back the eccentric spring and collar? Thanks -

Need help with Singer 211U566A

Parfektionisto replied to Parfektionisto's topic in Leather Sewing Machines

Hi BdB, thank you so much more the video, and thanks Uwe for making this video. Is this the pin you are talking about? -

Need help with Singer 211U566A

Parfektionisto replied to Parfektionisto's topic in Leather Sewing Machines

Hi BdB, Thanks for your input on this, but as I mentioned earlier, I know how the plunger works, and how to adjust the stitch length when the machine was still in good working condition, and I have 2 of this machines, one of it is in good working condition, so the plunger is neither broken, nor I didn’t push deep enough into the groove/slot. See this new video below, the disk doesn’t move when the plunger is set into the groove/slot. The only strange thing is, when I turned the hand wheel in either direction, it doesn’t come to a halt, that’s probably the catch which I can’t figure what went wrong. -

Need help with Singer 211U566A

Parfektionisto replied to Parfektionisto's topic in Leather Sewing Machines

Whichever direction I turn the hand wheel it doesn’t come to a halt now, which I thought what you said might be possible -

Need help with Singer 211U566A

Parfektionisto replied to Parfektionisto's topic in Leather Sewing Machines

Hi Folker, Thanks for replying. As I mentioned before the machine was working perfectly before, so I know exactly how the plunger works and I actually have 2 of this machines. The pulnger does get into the grooves in order to adjust the stitch length with the hand wheel. Everything was working perfectly, then all of a sudden this happen. Now I can’t adjust the stitch length even when the plunger goes into the grooves. This is what that puzzles me.