SolarLeatherMachines

-

Content Count

248 -

Joined

-

Last visited

Posts posted by SolarLeatherMachines

-

-

On 8/24/2020 at 6:50 PM, theleathersnob said:where do you get your info from ?

Leather in Texas is a super small world.

-

12 hours ago, Arturomex said:Not looking to jack this thread but what does "run 1 needle size down" mean?

It generally means to use 1 size down from the nominal needle size. For example, a 441 clone sewing a size 138 thread would normally use a 160/23 needle. But on a 1341 clone, it would sew better with a 140/22 needle.

-

1 hour ago, Joe112 said:After finally reaching tech support I was told this back stitching was acceptable for the machine.

*sigh* No, it's not. This is a common problem with the Juki 1341 style of machines. The back stitch should be adjusted to very closely match the forward stitch. The problem is that most techs don't now how to do it. Some will actually say it CAN'T be done. But it can. You have to get under the the head, and carefully adjust the rocker assembly. It's a painstaking process, and you have to know exactly what you're doing. Regarding thread in vs thread out, well, that's not much help, since you'll almost never use the machine with the thread out. The machine should be adjusted so that it sew correctly backwards WITH thread, otherwise it's pointless.

I would add that it seems you're using a pretty severely mismatched thread & needle combo. I don't know what size that you're using but the 1341 clones usually sew upholstery grade leathers best when you run 1 needle size down. -

2 minutes ago, turbotexas said:These tiny Allen head screws in the bottom... I’ll have to find a Allen head that small somewhere!

Welcome to life with a sewing machine. They probably 3/32 or so. might be 2mm. Amazon sells them. I used to go through dozens a year. OR you could take it to a reputable dealer and have them do a complete service for you and fix that. That's actually what I would suggest.

-

On 5/7/2020 at 1:01 PM, Chakotay said:I'm scheduled to get an online order today. It'll be sad to see their retail stores go away. Hopefully they at least maintain an online presence.

But it does make me wonder how they screwed this up: You're practically the only 'player' in the leather game (yes, I know there's other sources . . . you know what I mean). Was it just mismanagement? Poor quality? Bad customer service? Just a dying craft not enough people are interested in?

All of the above. But mainly a dying craft. Tandy had tried to rectify that by letting go of older folks, and hiring younger people. But they still focused on western leatherworkers, and almost completely ignored the cos-play and renaissance booms that were happening. They also tried to make their pricing more transparent by eliminating the tiered pricing levels. But the wholesalers immediately shifted to other suppliers, and the retail gains weren't enough to fill the gap.

I know a lot of folks don't like TLF, but they've served the leather industry well for a long time, and many of us got our start there. If they leave the market, given the current trend of aging population, there's not going to be anyone big enough to fill all the gaps. Big cities will be serviced, but the small shops will all go away. Considering that they're still in the middle of multi-year leases in many locations, I'd be very surprised if they didn't declare a chapter 11 bankruptcy, restructure their debts (including retirements, if any) and re-open. That's usually how this kind of story goes. -

The real problem you're having is that the plate you're pointing to is bent. The plate is meant to limit the distance the arm travels in either direction. It is generally NOT meant to lay flat on the machine, it's meant to be an adjustment plate. But with years of use, your plate has bent. Try straightening the plant out perfectly straight and see if that doesn't help.

-

Send me a pm with what you need. I have some stock left. Eddington is mainly a military supplier. They’re probably buried with emergency military requirements.

-

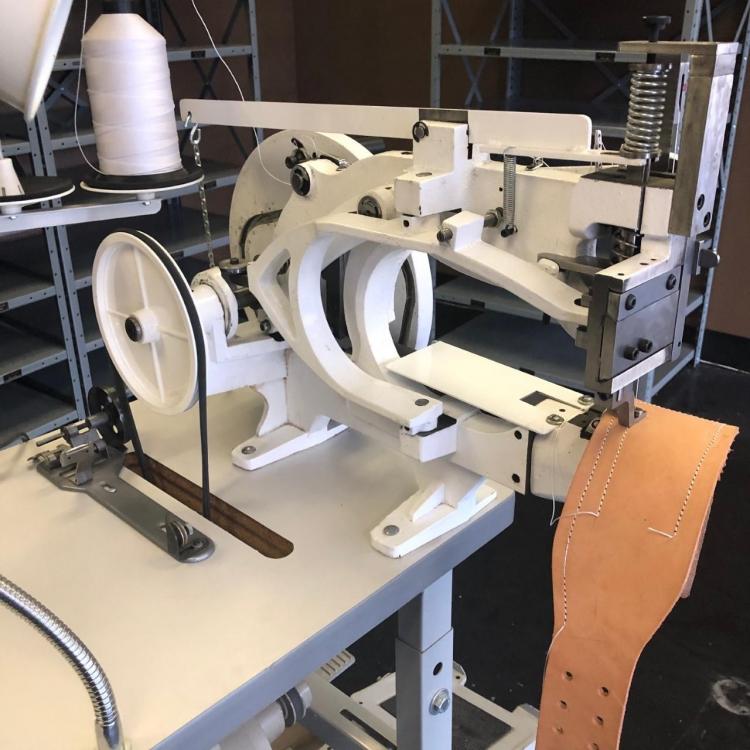

$ 600. For sale is this Ferdco 6/6 Heavy Leather Stitcher.

This machines has been cleaned, refurbished and tested. It is stitching straight & tight stitches. It has both a hand operation mode and a powered operation mode. Capable of stitching up to 1" of veg tan, it's perfect harness, tack and holsters.

Cash Only, no warranty provided. Just want it out of my way.Machine is very heavy. You will need a truck to move it. If you're looking for a heavy leather stitcher under $1000, this is it. Don't pass it up. I'm in Dallas, and will not ship.

-

Hello All,

Yes, we have decided to close the doors. This was not a decision taken lightly. Current import tariffs and business relationships have, in my opinion, made it impossible to provide excellent products at reasonable prices. So, we have decided to make a smooth transition to closing.

I may make the videos available in the new few months, but for now, had to close the channel because of copyright violations.

If you purchased a Cowboy machine, your warranty is through Cowboy USA. You may contact Cowboy through Neel's Saddlery & Harness http://www.neelsaddlery.com/index.htmlThank you all for the opportunity to serve you and the industry for the last 10 years.

Best,

Alexander.

PS, I have a few personally owned new 4500s with all optional attachments that I'm selling locally for $2400 each. Contact me directly if you're interested. I am in Dallas and I will not ship.

-

29 minutes ago, Teslabolt said:Found a more likely culprit to several woes on this machine. The presser bar extension was bent. Is this common on these? How does that even happen?

Commonly known as "buckling". Too much compressive force on a rod will cause it to bend and deform. The longer and thinner the rod, the lesser the force required to buckle.

F = n π2 E I / L2 is the Euler formula for long, slender rods if you're interested.

At some point, the machine forced to sew something stiffer and harder than it was designed for, causing the rod to buckle. -

For future reference, it's possible to use a small, thin cutting disc on a dremel, and cut ACROSS the screw hole. Then cut down into the bar and into the broken screw, creating a flat head screwdriver slot. You should be able to then use a small screw driver to turn it out. The existing threads are minimally affected and still work well. The cuts across the rod are minimal, and don't really weaken a steel bar that has a tensile strength of 57,300 psi. Obviously, this is a last option...but it's still an option.

-

On 10/3/2019 at 3:28 PM, JLSleather said:As of 10/01, 43 of 50 states now collect sales tax whether they are located in your state or not. Are we all complying with fed law?

Almost every state has a minimum dollar amount that must be sold before sales tax for that location must be collected. Usually that minimum is 100K. This was done to specifically protect small businesses.

-

Try this.

-

On 8/3/2019 at 3:07 AM, Matt S said:@jrprottas bear in mind that those "portable" setups are still quite heavy. The head alone on a 3200 must be over 100lb.

Our 3200 HC weighs 105 lbs. As Wiz says, it's a Barney handle, only made of stainless steel. I looked a long time before I found a handle that was really nice, and really comfortable. If I was going to do this, I was going to do it RIGHT. You can attach them to any wheel that you can drill and tap, but most of the lightweight machines have hand wheels that are basically sheet metal, and not suitable for the heavy stainless steel handles. Might be ok for the small wooden handles Wiz is talking about.

-

23 minutes ago, mikesc said:But, What I don't get is why in the USA , businesses close for the entire weekend, ( which is often the only time available to shop for others, potential customers, who can't get away during the week, because their boss says no, or because they too are one man bands themselves and are open all week ) rather than do what so many countries do, close on Sunday..and also on another week day..like Monday ( gives a two day break )..or Wednesday ( mid-week break) ..That is still two days off..

It's all based around trucking. Trucking companies don't deliver on Saturdays much, and not at all on Sundays. They often deliver on Mondays, and if you're not there to receive a shipment, it's usually a $150 charge for re-delivery. Not to mention the other 'box truck' deliveries on mondays as well. AND the phone absolutely blows up on Monday morning with people who need help and try to call in before leaving for work in the morning.

I seriously struggle to get certain tasks done. Mainly because I'm in the shop SO MUCH. My truck has needed an oil change for about 4 weeks, and I can barely get to the bank to cash my own paychecks. But if I'm away from the shop for more than 10 minutes, I get a phone call or a nasty-gram about how I'm 'never at the shop!' -

1 hour ago, mikesc said:I think Solar is the one he was referring to..which is shut on weekends.

Shut Sunday I can understand, ( everyone could do with a day off per week, even if they are not religious ) but to shut Saturday too..unless the business owners ( not thinking only of Solar there, but in general it seems weird to me for any business to be shut all week-end ) are orthodox..?

Here lots of places are shut Sunday, and from 12.00hrs 'til 14.00hrs on all the other days..which, as I always think when they tell me , means they are only catering to the unemployed or the retirees, because every body else is working ( and would need to take time off, or close their own business to go shopping ) when they are open..

Then again, I haven't been "open to the public, or any type customers" on any day of the week, since 2003..still in business(es), but no "face to face" on my turf.

Starwind0 , I hope that you find someone who is willing to stretch their opening times or days to accommodate you, and exchange your money, at a fair price to you both, for a machine that you'll be happy with.I AM Solar Leather Machines. I'm 47 yo, and I work from 7 am to about 6:30 pm Monday through Friday. I NEED SLEEP. And to spend time with my Wife and Family. And so do my employees. So, Yah, we're closed on weekends.

-

Sold! Thanks for looking!

-

Wow. That's awful. I hope it gets resolved very quickly

-

10 hours ago, Wizcrafts said:Cowboy/Hightex makes programmable pattern stitchers and we have 2 Cowboy dealers and the USA Rep on this forum.

Even a used programmable is going to be $15K or so. A new one can run up to$20 to $30K, depending on options. I have no used ones in stock, and I don't believe the other dealer does either. Contrary to popular opinion, these programmable machines just don't sit around. They are reprogrammed for a different task, and put back to work, sometimes in the same company, sometimes in a different company.

Call Ryan Neel of Neel's Saddlery & Harness to talk about a new one.

-

23 hours ago, mikesc said:Funny how Pinterest never encourage / help people to use Images that belong to Getty Images..Could it be because Getty Images have bigger, better lawyers than Pinterest

and Pinterest know that what they encourage and help is illegal..as is their site..

and Pinterest know that what they encourage and help is illegal..as is their site..

Yep. Getty images is EXTREMELY aggressive about their IP. I've purchased items from them in the past, and was warned EXPLICITLY about the ins and out of the licensing agreement. I had some knowledge and wanted to make sure not to cross the legal line, so I asked several pointed questions. I was told that they use a search engine style system to crawl the web, looking for their images, and flagging those that aren't licensed for review. I wouldn't be surprised if half their staff are focused on legal action.

There is another member here who related his experience with Harley-Davidson from several years ago. I read his story, and it was not pleasant, and something I vowed to avoid, and help others avoid as well.

-

You created a new work out of previously copyrighted work owned outright by another person/company, and intend to sell it for monetary exchange, without due compensation for use of the original work. The original work has been modified & edited from its previously published format without explicit permission of the copyright holder. This is CLEARLY illegal. Not to mention, there's also a strong argument for trademark violation as well, which is a MUCH lower legal bar than copyright. You REALLY should just toss it.

-

Sold! Thanks for taking the time to look. - Alexander

-

I'm not terribly knowledgeable about the Consew machines (I'm a Cowboy dealer, and I don't profess to know all machines!), but it seems that the primary differences seem to be that the -S2 is an older model, but instead of black oxide on the cover plates, the S2 has brushed stainless steel. Also the the S2 has an rotating inner cover over the center of the bell knife which seems to make it easier to eject leather scraps, and easier to clean. Also, it seems like the S2 is slightly larger than the S4 in length, but only by a small amount. Operation, performance, and adjustment are all the same. Overall, more stainless, more brass, a little heavier casting. Generally what you see from all the machines in that time period.

-

3 minutes ago, DrmCa said:A million dollar question is how much?

Ah!! Sorry forgot that! Gimme a second.

Cowboy 4500 foot lift

in Leather Sewing Machines

Posted · Report reply

No longer the case, Wiz. The factory changed the bell crank mount at the top of the linkage so that the bell crank bumps a stop before going past 7/8's inch. I have no idea why they did this, but has caused me a bucket of headaches in the last year.