-

Posts

20 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by Thatone

-

-

Can I know more? maadgoods@gmail.com

Thanks, Marie

-

Selling my trusty Juki 563, I have installed a servo motor last year. Its a great work horse. I've been using it for sewing leather and heavy duty canvas. Finally upgraded to a cylinder arm machine and need to make some space.. I am asking for $999 - local pick up only please, I can't even think of shipping this thing.

-

Hey, hoping to get some opinions on Yamata cylinder arm sewing machines. They keep popping up in my search (on the market for a refurbished machine) I can't find any reliable reviews. What is the shank, max needle size, and is it over all a decent machine?? I work with veg tan 9oz max, bags mostly.

Any opinion helps, thank you!

-

Ok,

brmax: their take was that there is no issue ....

I am using 135/16 NW needles with 69 bonded nylon - I do switch between canvas and leather. I adjust the tension accordingly - One mechanic made the thread tension super loose and the issue remained - other guy tightened it so hard I could not move the upper thread freely - both instances I asked if this is the appropriate tension - both said yes.

Correct needle breaks on the upstroke - clean break on the bottom layer of the material - usually without a sign of a struggle, it just breaks off.....I installed servo and made the machine super slow which I thought might have been a problem - jamming the needle in too fast.

UWE : It is hard to caption it as it happens very randomly - I was curious if any one is familiar with this behavior in particular with LU-563, since I dont really know anything about the machine. I thought thats something JUKI 563 is famous for... Simply put, if the material isn't two thin-ish layers, no way I can reverse without having to walk the needle manually.

Thank you all, I appreciate your input!

-

Hello everyone,

I am running out of ideas on what to do with my JUKI LU 563. I had two repair men to come and check, both of them told me the reverse stitch works fine - when I sew on leather and press it it usually breaks the needle, it is unreliable to use - so I have to walk back every beginning and end of every project - the sync of the bottom feeder is fine, but sometimes it happens that the needle breaks at whim on its way back up from the picking up the bottom thread.

Does anyone else have this problem? Any tips anyone can give would be greatly appreciated, I dont really want to sell the machine as everyone keeps telling me how amazing it is, but I am so frustrated with it!!

Thank you!

Marie

-

9 hours ago, MaxMizur said:

Makers Row is definitely the best place to start.

Oh man, how did I not know about this treasure??

Thank you!

-

Looking into having some backpacks made, not a big run at first, but progressively we can get to a few hundreds a week. The preference being a US based business with an impeccable quality of work and flexibility on the amounts of pieces produced. Where do I look for such a place? I have visited a couple of places in L.A. but no one I would consider.

Thank you!

-

I saw this at Savmore the other day, the name was Dakota cognac, around $6/sq.foot

-

-

May I ask what whas the price of your binder? I spoke to them few months back and they quoted me somewhere around $1,200 and additional sewing machine - I dont think I am in a need of $1,200 binder attachment.

-

Hello!

I am seriously considering selling my flat bed walking foot Juki and getting a cylinder arm instead. I want to do simple binding on my canvas and leather bags, but it is near impossible to find a heavy duty binder for this machine. Is there a cylinder arm binder attachment?

I usually work with 15-18oz cotton canvas and max 5-6oz veg tan hides. The mouth of the binder would have to be pretty wide.

Any cylinder arm users can give me advice?

Thanks!

-

You are guys are awesome! Great work on those bags!!

NVLeatherWorx i some what succeeded:) thank you for the instructions!!

-

On 8/5/2017 at 9:31 PM, NVLeatherWorx said:

These handles on all LV bags are actually a thin veg-tan style leather that is wrapped around a braided nylon cord (much like a rope) and then stitched together. I have replaced/repaired the handles on LV bags for about the past 7 years and was quite surprised at how simple and cheap quality they were when you take into consideration the price of one of these bags. I have probably done repair/replacement work on over 200 LV bags in the past few years and I have accidentally become the local go to repairman for these things; I keep getting contacted by people who were referred by previous customers. These bags are nothing really extraordinary once you get into their construction and are very easy to work on.

I would say that you can replicate this style handle with any thinner leather; all you need is the right sized core (cord/rope) and some adhesive and away you go.

That encouraging and disappointing in the same time!:) I know the theory behind, just never succeeded in recreating it myself. I will persist! thank you!

-

YOu did this as a novice!!?? My hat off to you..... Is it lined?

-

I love the handles on a speedy bag by LV, but I am only successful at making them with a thicker veg tan leather - i have a beautiful chrome leather and it seems so thing and flimsy to make the tip of the handle. Any proven methods at how to do that without a fancy skiving machines and laser cutters?

Thank you!

-

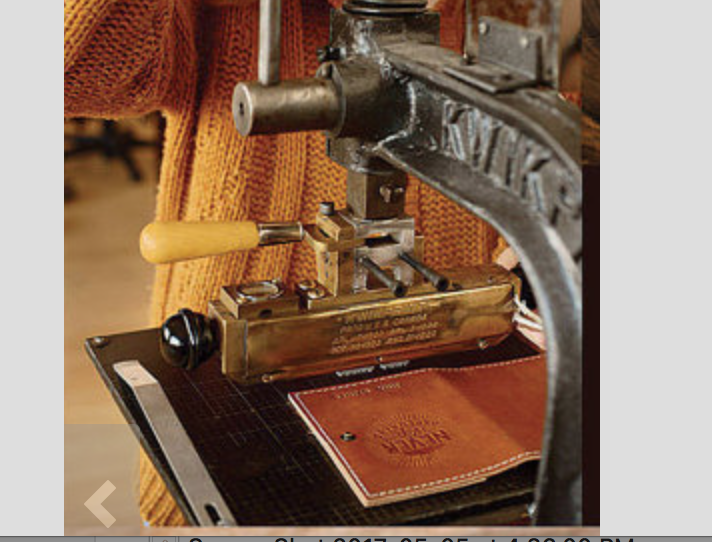

Hey guys,

so I finally gave in and figured I'd better get one of those fancy presses for my stamping.

Now, which one do i get? I am pretty set on 1ton press, but most of them seem little toys.

Any recommendations? Much appreciated!

M.

-

You guys rock, thanks!

-

-

Hello,

I am trying to find some info about a customized alphabet set that I can use to stamp with an arbor press.

I really want to be able to put initials on my leather but cant find where to get the whole set up - I want a hand press, not a burning iron.

Any ideas who makes these things and are these alphabet sets usable with arbor presses?

Thank you!

M.

Juki- 563 Walking foot

in Old/Sold

Posted

In a great condition, new servo motor, wonderful for leather work. Local pick up only ( Los Angeles)

$800 or best offer.