-

Posts

21 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Carrie88

-

Thanks all for the advice.

-

Hi, can anyone tell me if this motor is worth anything? would someone reuse this? I took it off my machine as replaced with a servo. The clutch motor was way too fast and powerful for me. The original motor worked fine at the time. I just don't want to throw it out if it has a use. Thanks for advice.

-

Which servo motor should I buy in Australia?

Carrie88 replied to Carrie88's topic in Leather Sewing Machines

Well I wasn't actually there when the machine was serviced, my partner was so I got the info second hand. The serviceman said that by having my servo motor set only to level 1, which is the slowest it can go, the machine was then putting too much tension on the thread and it kept snapping. By turning the machine up a few levels, this has reduced the tension load placed on the thread by the machine. Now as a relative newbie I don't know whether this is poppycock or not I do know that my machine is running better now. I gather you may be thinking that it shouldn't matter what speed the servo motor is set at? -

Consew 226R thread breaking and tension controller sticking

Carrie88 replied to Carrie88's topic in Leather Sewing Machines

Thanks CowboyBob - I am taking more notice of this top thread tension now and as you said it has reduced the number of times that the thread tangles underneath.- 27 replies

-

Consew 226R thread breaking and tension controller sticking

Carrie88 replied to Carrie88's topic in Leather Sewing Machines

An update to this thread for any newcomers with an old Consew that may have similar problems and be reading this right now. Despite the guidance provided in the machines manual (and the Singer manual which is virtually the same) my machine in particular does not really like it when you mess around with thread sizes and needle gauges. It is very happy at the moment sewing with Tkt 60 (v46, T45) thread and a 14/90 needle. Also the instruction manual says to put the needle in the wrong way around, it could just be the way I was reading it, but the scoop out section near the eye of the needle needs to face TOWARDS the bobbin housing. If I put Tkt 30 (V92, T90) and a 19/120 needle, the machine will sew for a while but then gets very unhappy again and the thread tangles. Same happens with Tkt 40 (V69, T70) and a 16/100 needle. I put the smaller and needle and thread back in and it's happy again. Some of these combinations seem to have the thread a bit fat for the needle, like there is some friction so by going up a needle size it does make a difference, but I think I still have some tension issues on my machine. So this is probably just an idiosyncrasy of my particular machine or maybe I don't know quite enough about how to adjust it properly yet. I was hoping to use bigger thread to mimic the look of hand stitching on thicker leather, but I am happy for now with the look of the ticket 30 thread. Also the addition of the servo motor really was a game changer (thanks to the advice of users on this forum for guiding me through that!). I have also had the machine serviced by a professional since then and there were a few issues with it. I had the setting of the servo motor too slow, he adjusted it up to 20 and that made a big difference. Also the check spring part featured in the video above by Uwe, the serviceman actually bent the already bent part of this in further as it was not preventing the thread from jumping out during sewing. Note - this was a brand new part purchased from SouthStar (http://southstarsupply.com ) who I totally recommend if you need Consew parts. There was nothing wrong with the part as such, but the modification made a difference on my machine. Happy sewing! and don't give up, it takes perserverence! ps. I did also end up figuring out what all of the attachments, edge guides etc do.- 27 replies

-

Which servo motor should I buy in Australia?

Carrie88 replied to Carrie88's topic in Leather Sewing Machines

This is a VERY delayed response, but I just wanted to finish this thread by adding what I ended up with. I bought the Ho Hsing motor that I linked to originally. http://www.sewingmachinesaustralia.com.au/shop/buy-accessories/motors/ho-hsing-g60-servo-motor.html I am very happy with it, it was very easy to install, the hardest part was the weight of the sewing machine and the weight of the original motor. The instruction sheet is a little quirky, you kind of have to look very closely for how to operate it and change the speed. I would recommend this motor to anyone who was in the same boat as me, aka giant beastly industrial machine that you can't control :). One thing I will point out, having just had my machine serviced by a professional - I had the speed control set too low. Apparently this was creating far to much tension in the machine and as a result my thread kept snapping within a few stitches. I now have the speed sitting on 20 which is slow enough to control but allows the machine to run better. Apparently having it set at one or two was likened to driving up the blue mountains in first gear... -

Thanks for the advice, the aspirator really makes sense and I didn't notice that one was not attached. Hand skiving is messy enough. I'm patient, I'll bide my time and hopefully pick up something second hand for a reasonable price.

-

Hi all, just wondering if anyone has heard of the machine below and whether it's a good model? I've had a few sales this year and I think investing in a skiving machine will be a game changer for me. I make a lot of bags and smallish items where bulk on the seams is problematic. I have a small hand skiver but it's not really cutting it GOLDEN WHEEL CS747 http://www.imsmachines.com/products Not really sure where else I would buy one from? Appreciate any feedback. Carrie

-

Which servo motor should I buy in Australia?

Carrie88 replied to Carrie88's topic in Leather Sewing Machines

Thanks Darren, that looks reasonable. For some reason the messaging function is not working for me. Is there another way I can contact you? -

Which servo motor should I buy in Australia?

Carrie88 replied to Carrie88's topic in Leather Sewing Machines

Thanks everyone, very helpful info. I'll do some more comparisons. Seems like the brand doesn't really matter too much? Silverback - can you tell me the specific name of the facebook page? I did some general searches for leather Australia but couldn't find much. thanks -

Which servo motor should I buy in Australia?

Carrie88 replied to Carrie88's topic in Leather Sewing Machines

Hi, Well this brand - https://reliablecorporation.com/collections/motors - seems to get good reviews on a few different sewing forums, I was particularly reading some threads on the hotrodders.com forum in the upholstry section. There are a few sellers of these on ebay and other sites. I was looking at this one - http://www.allbrands.com/products/10568-reliable-sewquiet-6000sm-variable-speed-dc-servo-m - where they retail at $199US. In Australia I was looking at these - http://www.sewingmachinesaustralia.com.au/shop/buy-accessories/motors/ho-hsing-g60-servo-motor.html - at $425 which is really a lot more than I was hoping to pay. I just don't want to order something online and have it turn up and feel like a dummy because I didn't consider something important. Carrie -

Hi all, I have a consew 226R and I'm ready to put a servo motor on it for more control. My problem is that most of the recommended motors on leather forums, like the Reliable motors (which seem reasonable for well under $200au), are all for sale overseas or on ebay. Whilst some of them look like they have the voltage option for Australia, which is 220v, I can't tell if they would then have an Australian plug. The motors that are for sale from Australian vendors all look extremely expensive to me by comparison, around $400au. I'd really appreciate any info from fellow Aussie leather workers who have been down this path. And from anyone else too of course, if you have seen this type of question before. Regards, Carrie.

-

Consew 226R thread breaking and tension controller sticking

Carrie88 replied to Carrie88's topic in Leather Sewing Machines

So I have no idea what the big screw is for or even if it goes with the machine, I also can't work our where to put the weird hook with the slotted end but I'm pretty sure the net thing is a roller foot or edge guide of some type? In the next photo these seem to be feet for working with big edges, like the beading on car seats or something? Appreciate any tips here. I read the other thread on home made edge guides, but they didn't really help me with the above attachments. Thanks.- 27 replies

-

Consew 226R thread breaking and tension controller sticking

Carrie88 replied to Carrie88's topic in Leather Sewing Machines

- 27 replies

-

Consew 226R thread breaking and tension controller sticking

Carrie88 replied to Carrie88's topic in Leather Sewing Machines

Thanks leecopp - I also have a copy of that manual which I downloaded from the web - it's definitely more helpful than the consew manual. I also have a copy of the parts manual which I downloaded from South Star Supply online which has been very helpful when dismantling and reassembling for cleaning etc. When I bought the machine many of the parts were not attached, there was just a big bag of random screws and rods and things. NCArcher - that is indeed a very kind offer. I live near the airport. I am not financially ready to invest in a servo motor yet but will definitely be in touch for advice when I do. In the meantime I have adjusted the brackets that attach the foot pedal, and I can control the machine fairly well. I have found this is also easier when the room is warmer (its winter in Aus currently). It seems a bit smoother rather than jarring fast and slow. I have also found a bunch of extra parts which I will post a photo of. I think they are additional feet with an edge guide, perhaps for top stitching? as well as a flat plate which I have no idea of how to attach, plus a roller guide. I'm hoping that if I learn how to use these, I can really start to sew in straight lines! Please don't laugh - but is this what this flat piece is for?- 27 replies

-

Consew 226R thread breaking and tension controller sticking

Carrie88 replied to Carrie88's topic in Leather Sewing Machines

Thanks leecopp - I also have a copy of that manual which I downloaded from the web - it's definitely more helpful than the consew manual. I also have a copy of the parts manual which I downloaded from South Star Supply online which has been very helpful when dismantling and reassembling for cleaning etc. When I bought the machine many of the parts were not attached, there was just a big bag of random screws and rods and things. NCArcher - that is indeed a very kind offer. I live near the airport. I am not financially ready to invest in a servo motor yet but will definitely be in touch for advice when I do. In the meantime I have adjusted the brackets that attach the foot pedal, and I can control the machine fairly well. I have found this is also easier when the room is warmer (its winter in Aus currently). It seems a bit smoother rather than jarring fast and slow. I have also found a bunch of extra parts which I will post a photo of. I think they are additional feet with an edge guide, perhaps for top stitching? as well as a flat plate which I have no idea of how to attach, plus a roller guide. I'm hoping that if I learn how to use these, I can really start to sew in straight lines!- 27 replies

-

Consew 226R thread breaking and tension controller sticking

Carrie88 replied to Carrie88's topic in Leather Sewing Machines

Adjusting the timing sounds like a lot of work just to change threads. Perhaps I'll just stick with the thicker ones. I'm also a bit confused about needles - my manual says to use 135x17 which I am, but I have seen users of this forum saying that 135x16 are for leather work? should I be using these instead? Also, I'm wondering if my tension discs are just not working properly - the tension is so tight, no matter how far out I wind the tension nut, it can be out as far as possible without falling off - and the thread is still so hard to pull through. I've see these whole tension assembly's for sale - perhaps I should just replace it.- 27 replies

-

Consew 226R thread breaking and tension controller sticking

Carrie88 replied to Carrie88's topic in Leather Sewing Machines

Is installing a servo motor something that a non-sewing machine mechanic can do? or is that not recommended? I would really like to do so but I'm worried it could be too expensive. The thought of the machine stitching slowly is a dream! I've been using Tkt 20 (#138) - so this is also M20? that's good to know, I got pretty confused about that looking at thread for sale online in Aus. But I really wanted to use lighter thread for more inconspicuous topstitching. The lowest I've been able to go is Tkt 40 (#69) but I really wanted to use Tkt 20 (#46). I have found that my machine doesn't like any needle smaller than 120/19. The 14 and 16 size needles just seem to pierce the thread or the stitching really puckers up and then snaps. As soon as i put the bigger needle back in, it's happy again and starts stitching normally. I'm sewing quite light leather, making bags, kind of like pencil cases or zip up pouches for laptops etc. So the leather is no heavier than what would be used for a leather jacket - but it becomes double on the seams, or sometimes four thicknesses if I've added a little tab or something decorative. But I am also making little coin pouches using sheepskin garment leather which is very thin, but there is also a fabric lining and zip - so it's more than my home Janome could handle. So I topstitch along the zip on both sides and while the #138 or #69 looks nice on the bigger pouches, it doesn't look so nice on the smaller ones which is why I was trying to go down to thinner threads. Sorry I just realised I made a mistake, I meant to say I want to go down to Tkt 60 (#46) these codes are killing me!- 27 replies

-

Consew 226R thread breaking and tension controller sticking

Carrie88 replied to Carrie88's topic in Leather Sewing Machines

Thanks so much for the video, Uwe. It was very helpful and seems to have solved my tension problem plus my thread has stopped breaking. I think I was also using a needle that was too small for the thread - and it was kind of piercing the thread and tangling up. I have read all of the threads (no pun intended ) on this forum and so I have tried to match a few different thread sizes to needles sizes, for sewing lighter leather for bags etc. The thread sizes are so confusing, between the tex, the ticket and whatever other number they have. And then here in Australia, the numbers seem different again. I've just played around for a few hours and managed to sew a few things - but I can see it really takes practice and experience to create nice work with these machines. Now I just have to get the beast under my control - it's so powerful and just takes off if I put my foot down too hard. This is a wonderful forum for beginners, thanks to all of you for your help. Carrie.- 27 replies

-

Consew 226R thread breaking and tension controller sticking

Carrie88 replied to Carrie88's topic in Leather Sewing Machines

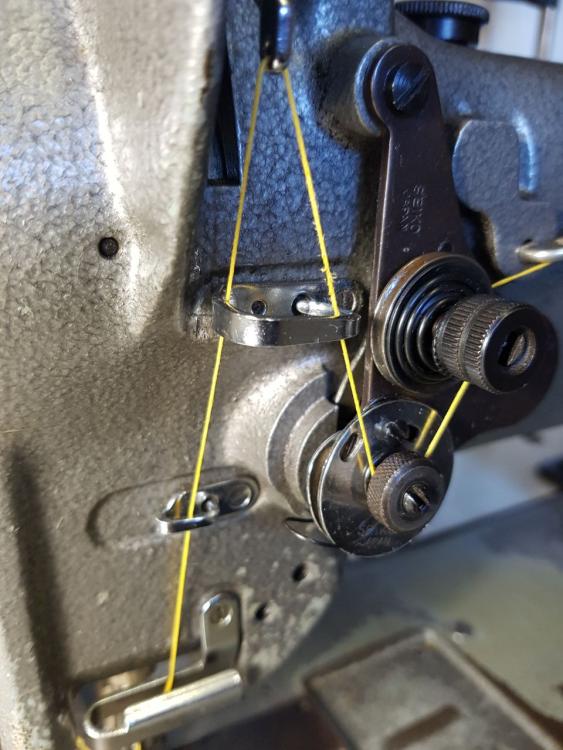

Hi, thanks so much for you quick responses. I will definitely stop putting the thread around the pin and just come straight out the bottom of the tension discs - that's really disappointing that what looks like a really helpful video, is actually wrong - a lesson learnt for me. Regarding the spring, so when the thread pops past the bent part of the thread controller disc, sort of sitting outside it (which I have tried to show in the last photo but it is not easy to see) and then rests against the spring - what stops it from jumping out again while you sew? I seem to have so much extra thread at the point when the needle is fully up, that nothing can stop the thread from just kind of falling off the thread controller.- 27 replies

-

HI, I am hoping to get some help with my Consew 226R. I have had it for a few weeks, purchased from an ex upholsterer. It was very dirty and some parts were not attached, so i have been cleaning it up, putting it back together and ordering the odd screw, spring etc online to replace things. I now have it sewing and operational, however I just can't get the thread tension right. I thread it up according to the manual (and according to the amazingly helpful youtube videos that I've found). But what happens it that the thread seems to be too loose when the needle comes up and then the thread jumps off the thread controller disc, out of the spring and then wraps itself around the back of the thread controller nut, or sometimes the back of the thread controller itself. I have tried various settings by turning the thread controller more to the left or more to the right, I have tightened the spring, moved the spring stop up or down - and I just can't crack it. I pulled to whole tension bracket set up apart and checked each component, and everything 'seems' to be working as it should. I have read posts on this forum referring to worn pins behind the bracket, but it's difficult to tell if this is worn, with nothing to compare to it too. Also, even on the few occasions where the thread does stay inside the thread controller for a while, the thread ends up breaking because it seems to get stuck up inside the tension discs and then it just breaks down at the needle. I got this machine quite cheap and I'm now feeling very frustrated that it won't even sew for 10cm without something going wrong. I'm really hoping there is something simple I've missed. Really appreciate any help offered that will save me going to a sewing machine mechanic just yet (will be my last resort due to finances) - and I can see that there are many experience users on this site. Carrie.

- 27 replies