stor

Members-

Posts

21 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by stor

-

Got a problem with my foot getting stuck in up positionen, i need to push it down after i lift the foot I have oiled all parts but cant figure out where it getting stuck. https://vimeo.com/337160562 /Stor

-

Thank you all for your responses ! This one is simple and perfect ! Thanks Dikman ! /P

-

My Juki lu 563 is coming along, change the hook to get it to accept a thicker thread in the bobbin and the new servo is doing a good job with my speed reducer, however, i got another problem. I would like to free up my right hand when i do reverse stitching and my question is ! Is there a way to disable the spring on the reverse lever so i don't need to press it down while I'm stitching reverse? /P

-

No worries ! Maby one of the guys above can point you in the direction of a seller if you dont wanna go thru the pain of 3d printing one, but if you do wanna 3d print one let me know and ill send you the file.

-

yes, thats the plan now when i know it works.

-

Slowest i could run on the slowest speed (500) The knocking sound is the hook hitting the needle, i just switched my hook (B1830-563-BA0) to get thicker thread at the bottom and i need to adjust the distance from hook to needle. sorting it out tomorrow. https://vimeo.com/323906546

-

I did find alot of 40-45 mm pulley but none that fit my 13 mm axel that my Jack have and i guess i could have spent more time to trying to find the right one but in the spirit of DIY whats the fun in that ? i learned 2 new skills and hopefully inspiring someone in the process. I keep you posted on the progress.

-

Thanks ! i was around for the original run of MacGyver ! Printed it in PLA as test, see how it holds up, where not sure it would work at all and my backup plan was to do a speed reducer with a large and small pulley. /P i sort it out tomorrow.

-

I got a Juki lu-563 and as soon as i got it i took the old clutch motor out and now i use it as a boat anchor I invested in a Jack JK-563A-1 servo motor and its nice ! However ! its abit to fast for me even at its slower speed and when i did some digging around i found that i wasn't the only one with that problem and tried to find a good solution for it without spending 2-300 euros on top of that and i figured a smaller pulley would do the trick but couldn't find any 40 mm pully for it. After some brainstorming i figured I just make a 3d model of what i needed and hired a 3d printer owner to print it for me and it arrived today, i needed to drill out the hole and do some file work to get it to fit and now it installed. I printed it in PLA as a test and gonna run in until it falls apart but im surprised that it works so well ! im totally happy with the speed now, i can do a recording if anyone wanna see the speed. Here is a few photos Kind regards Peter - Antfarm steel & leather

-

Thank you ! that fixed it and i went with a smaller needle aswell to get less blowout. /P

-

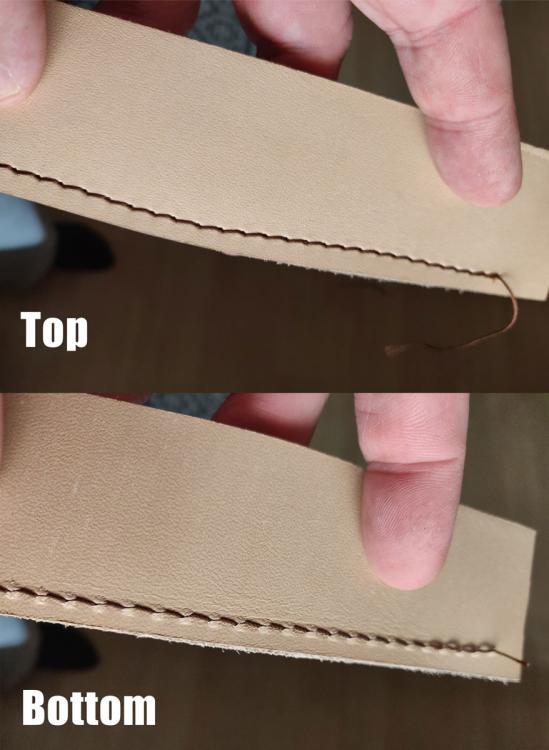

the problem isn't the knot, the problem is that the bottom stitch is tighter and digs into the leather more than the top stitch. Looked a lot worse with a TRI needle, using a RTW now, couldn't find any S.

-

My top stitches look great but bottom stitch is to tight and cuts into my leather when I loosen the top stitch nothing really happens except that the loop shows up in the bottom. Or maybe I'm using the wrong size needle? Or am i just being picky about how it looks? Using a Juki lu-563 - #15 thread and size 160 needle

-

Is it possible to make a embossing wheel using tinkercad

stor replied to chrisash's topic in 3D Printers and Lasers

Any proper 3d application like 3d studio max or Maya can extrude a black and white image and apply it to a cylinder they way you want. -

Help with replacing tension disk - singer 29k8

stor replied to stor's topic in Leather Sewing Machines

Thanks Jimi i will try that ! -

Bottom disk on my tension is broken off and i cant figure out how i get to it so i can replace it ! Its a singer 29k8. /P

-

I have a singer 29k8, is it possible to upgrade bobbin size from small to big ?

-

Thank you so much ! Notest i was missing the Oil cup spring aswell ordered them both. Whats the thickest thread / needle i can use on my 29k ?

-

Any chance you can scan it and post it here Glenn ? Would love to see if i can find the missing part aswell. Thank you so much for taking the time to look for it ! /Stor This made me do some research and and its crasy how much they go for

-

Thank you Thank you for taking the time, i appreciate it very much ! Thank you so much for sharing and taking the time, this is a good start.

-

First of all let me thank all of you that make the effort to share information on this forum, been a huge help while i started leatherworking ! So finally i got my hands on a singer 29k, its a 29k8 and according to the serial its made 1897 so happy 120 year birthday Its been served and a few years ago and no one have used it after that so all i needed to do was to feed it some oil, everything runs smoothly and im looking foreword to learn to work with her. I got it for 200€ and a nice bonus was that i also got the original stool with the singer. Done fair amount of research but cant really find much information about 29k8, closest i got has been in a few manuals that have 29k73, anyone have any information to share about 29k8 ? Here is a few pics /stor