Brtz

Members-

Posts

42 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Brtz

-

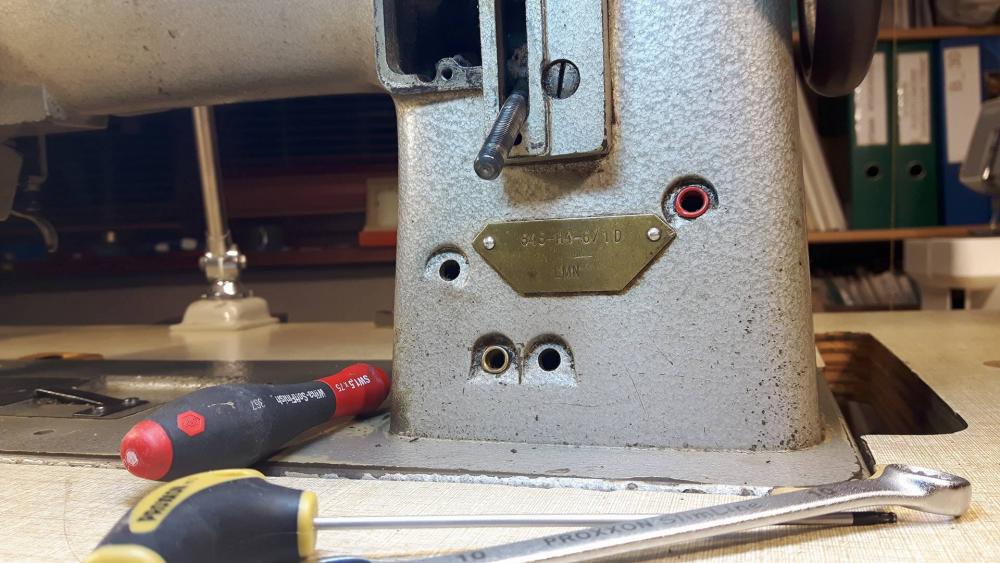

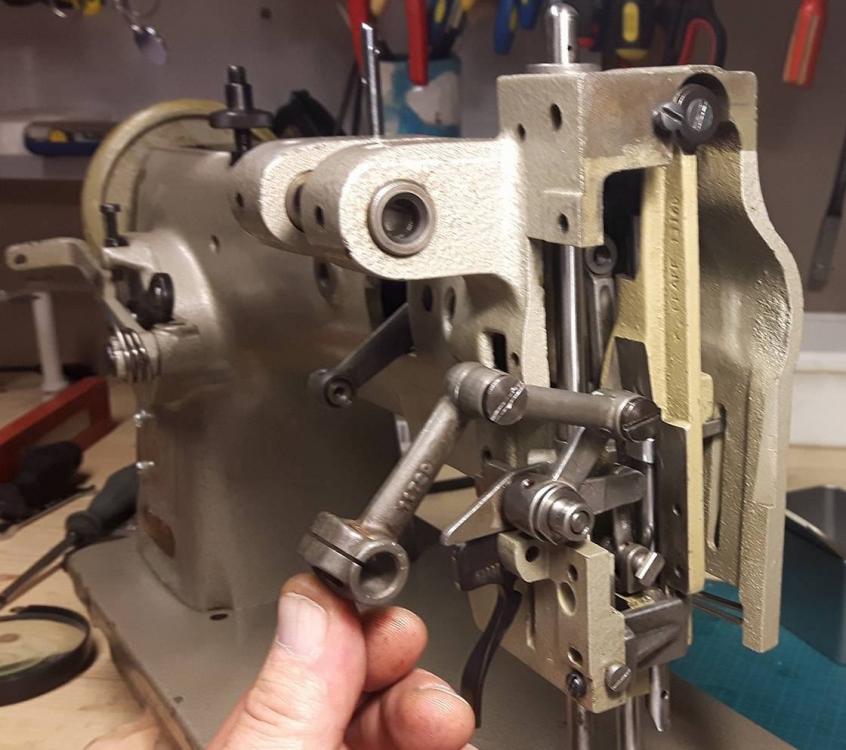

Glenn and Uwe - thank you. This introduction is very useful. I need help. Can you look at the end of the needle bar in my 545-H4 please? I cannot recognize if there is any component missing? What these two holes and a scarf are for? Is that wire on the lower end of the needle bar (now working as a thread guide) is an original part? I cannot recogize it in my part's list. Would you also suggest me what kind of grease should I use for the perpendicular gears? My machine was almost dry and the alu-covers were mostly out of the grease inside. I attach some photos I have taken during cleaning the machine. I am going to do some test sewing soon. Regards, Bert

-

Look what I found in the old barn! I wonder why feed dog goes only forward and backwards without up and down movement? Does this type have it? Starting restoration now... more photos soon. Regards. Bert

-

Pfaff 4145 (combination of Pfaff 145 and Pfaff 4143)

Brtz replied to Brtz's topic in Leather Sewing Machines

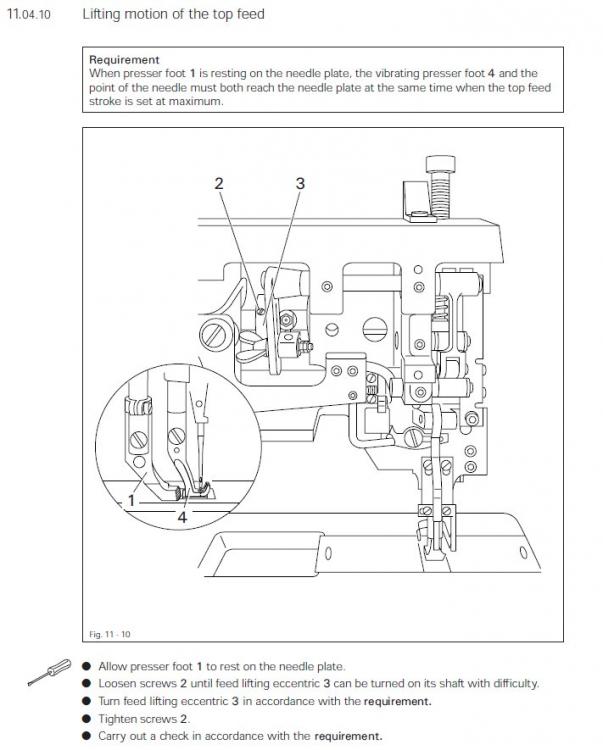

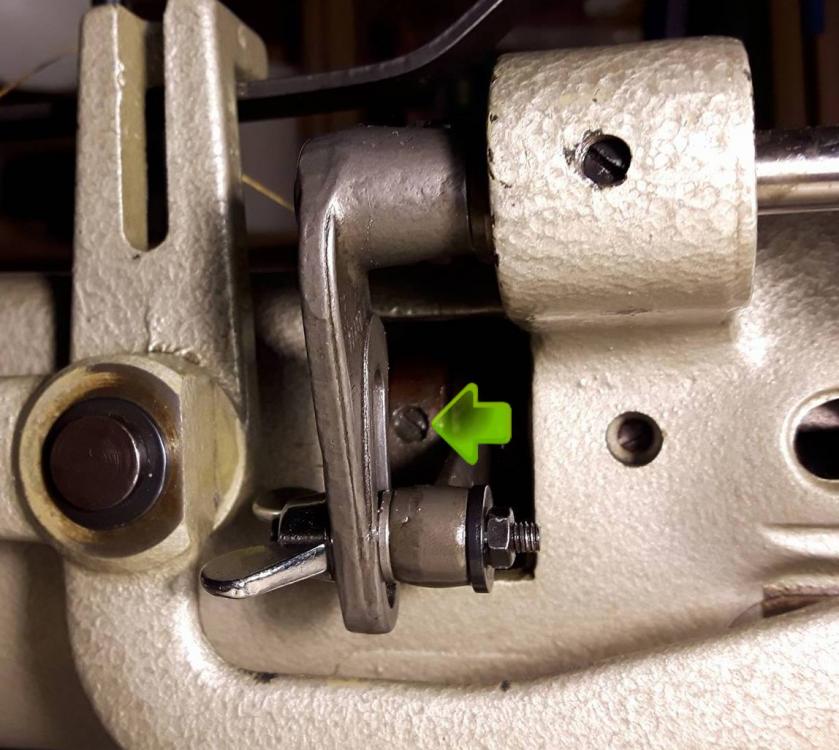

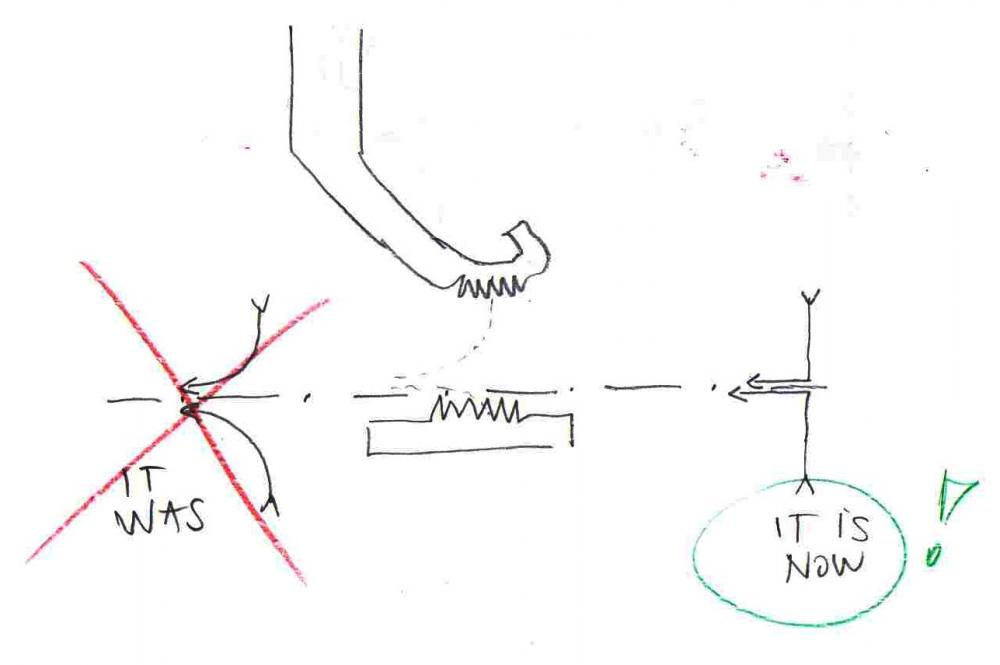

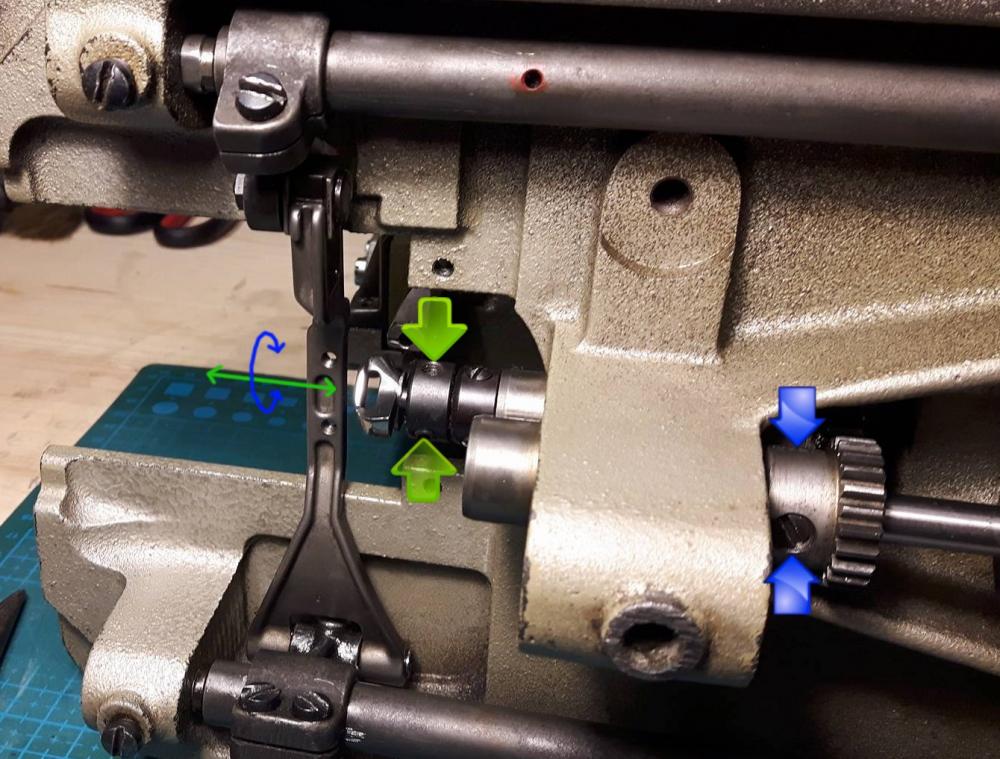

1. Seems I solved a gathering problem. Studying pfaff 1245 service manual I found how to adjust several very similar assemblies as in my 4145. Btw - this 1245 SM is availiable on keyston sewing website. One of the settings which appeared wrong in my machine was top feed lifting motion. I tried to draw a scheme of how this motion is now and how it was before the adiustment of feed lifting eccentrics. This eccentric is shown on the corresponding page of the SM and marked with an green arrow on the photo. Both feed dog and the presser have to stick together before they start backtrack. Previously they started moving back before the presser land on the feed dog. Sorry, I cannot explain it more preciously. Anw, it's done. 2. I took a risk of ordering a new looper on e-bay. I found that a Michael from 'kunpengsewingmachineparts' offers some parts for pfaffs. I ordered 1 PCS ROTARY LOOPER #96-795282-00 FOR PFAFF 63 and also a complete tension assembly and a double toe walking foot set for 145. I had no idea if the looper will fit but USD10 is not a fortune so... You can see the new looper on photos just to compare it's shape with an old one. Then BINGO! This one works much much better than the old one! With the new looper and the brand new springs in the tension unit the stitches are tight, smooth and even. The delivery from kungpeng is free and it took 21 days to get those parts in Europe. 3. I have replaced the tension assembly and a walking foot set. Then made some sewint tests, few photos and sew a machine-cover as the dessert. I think the restoration of 4145 is finished. Thanks for your help. Regards, Bert- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

Pfaff 4145 (combination of Pfaff 145 and Pfaff 4143)

Brtz replied to Brtz's topic in Leather Sewing Machines

Constabulary - honestly, I bought this machine for a scrap price just for saving it from further destruction. I adjusted it, replaced some parts, cleaned them and learned how it works - keeping 'old cast iron alive'. This was for me a great fun and learning. By the way, I joined this forum where there are many professionals and experts. As for the machine - I certainly will not use it for my own needs, because of his limited scope of uses. This machine is for sale now. If it does not sell, I am wondering if it could be reconstructed by replacing whole bottom part of the machine with a typical 145 class lockstich machine with the bobin. It's only a matter of time to find another scrapped machine in the local market.- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

Pfaff 4145 (combination of Pfaff 145 and Pfaff 4143)

Brtz replied to Brtz's topic in Leather Sewing Machines

I attach a pfaff 4145 sewing demo video. Thanks for your help. Bert- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

Pfaff 4145 (combination of Pfaff 145 and Pfaff 4143)

Brtz replied to Brtz's topic in Leather Sewing Machines

Thanks Uwe. And I am sorry. That question was misunderstanding, maybe because of my english. I asked if it is physically possible to make a single thread chainstich in a reverse gear - in general. Not only on pfaff 145. In my machine there is also exactly the same lever cover plate (named "scale") as in your machine which restrict the lever movement to the top position half-way around "0" stich lenght. But after removing this plate I noticed that the lever can move up to the very top also not only to its half way as the scale allows to. That's why I supposed that it would be possible that someone install wrong scale and the machine in real can also sew in reverse. I only doubted if it is possible to make a chainstich in the reverse movement in general. Sorry for that.- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

Pfaff 4145 (combination of Pfaff 145 and Pfaff 4143)

Brtz replied to Brtz's topic in Leather Sewing Machines

I know how to turn on a reverse mode on Pfaff 145 Uwe. Thank you. The problem is that flipping this lever up does not switching the machine to the reverse mode. It is passing thru "0" stitch lenght and begins to sew in... forward mode again- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

Pfaff 4145 (combination of Pfaff 145 and Pfaff 4143)

Brtz replied to Brtz's topic in Leather Sewing Machines

Hi, Stupid question: can single thread chainstich machine sew in a reverse mode? Bert- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

Pfaff 4145 (combination of Pfaff 145 and Pfaff 4143)

Brtz replied to Brtz's topic in Leather Sewing Machines

I just checked the left side looping and mirroring the needle. I had to lift a needle bar about 2mm cause tip of the needle hit the body of the looper. That is why I cannot agree the looper was designed to work having needle on its right side. The body of the looper has the rounded hole inside the body and the needle is coming into this hole when the looper is fixed as it was previously, having the needle on its left. Second bad effect of this experiment is that the needle starts stabbing the thread. So it means I had less then a little luck this evening :). Anw thank you Uwe for your suggestions. I am learnig a lot with all of you. As for the tensions I ordered a new check spring 91-010 023-05. I do not like the spring I have got in my machine. It works like it was from the tank. Regards, Bert- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

Pfaff 4145 (combination of Pfaff 145 and Pfaff 4143)

Brtz replied to Brtz's topic in Leather Sewing Machines

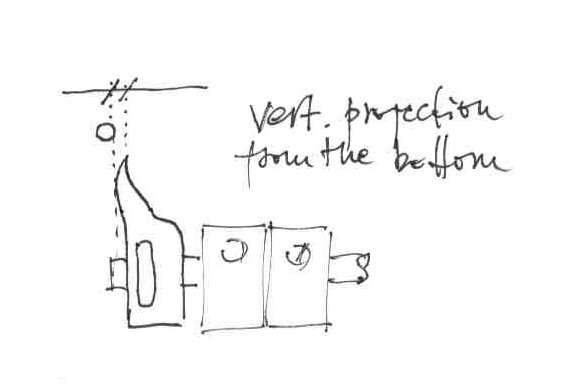

shame I did not check the part number earlier . Thanks Uwe. exactly that is no 102 025 looper but 233 094 'ersatz' probably purchased here in Poland http://www.bullmer.pl/pl/szukaj.html ok then. I have what I have so far. If anyone has heard about the original 102 025 looper I'd be interested in... I am also attaching 3 axis perpendicular view of the looper to show how it is curved. Also two general views. Sad. Bert- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

Pfaff 4145 (combination of Pfaff 145 and Pfaff 4143)

Brtz replied to Brtz's topic in Leather Sewing Machines

I am attaching the zoomed photo of my looper. It does not look grinded or reshaped... so you think that is bad looper? I also wouldn't like to try reshaping it by my own. Can you also have a look of how I am threading the machine?. There is still something wrong I am afraid. I have tension discs totally loosened and the check spring is set to the lowest workable power. But the friction resistance of the further thread guides (sloping arm, arm-shaft and on the needle holder) is still too big. The resistance is tightening the thread when I am trying to sew stitches longer than 4-5mm and the good starts to ripple. Changing the pressure foot power makes no effect. On shorter stitches it's better but still far away from ok. What am I doing wrong? Bert- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

Pfaff 4145 (combination of Pfaff 145 and Pfaff 4143)

Brtz replied to Brtz's topic in Leather Sewing Machines

Thank you Eric, I am going to correct the looper settings due to your comments. As I said I still work on the check spring action thus not every cycle the thread loop is created when the needle starts going upward or sometimes this loop is very narrow. Closing the point of the looper to the needle scarf let not to miss the loop by the tip of the looper. However yes, the point of the looper touches the needle slightly now. From the other side as whole hook of the looper is curved in the needle-opposite direction the tip of the looper is missing the scarf a bit further to the right side then the point of the looper (see pic.) Maybe that is the reason the looper is missing the thread loop temporarly? Bert- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

Pfaff 4145 (combination of Pfaff 145 and Pfaff 4143)

Brtz replied to Brtz's topic in Leather Sewing Machines

Spent half a day working on tensions. Uwe's film really helped, thanks. Here is the looper of my Pfaff 4145 in action. Greetings, Bert.- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

This topic was only to say "hello everybody" so I am moving the pfaff 4145 discussion to the new topic: Thank you, Bert

-

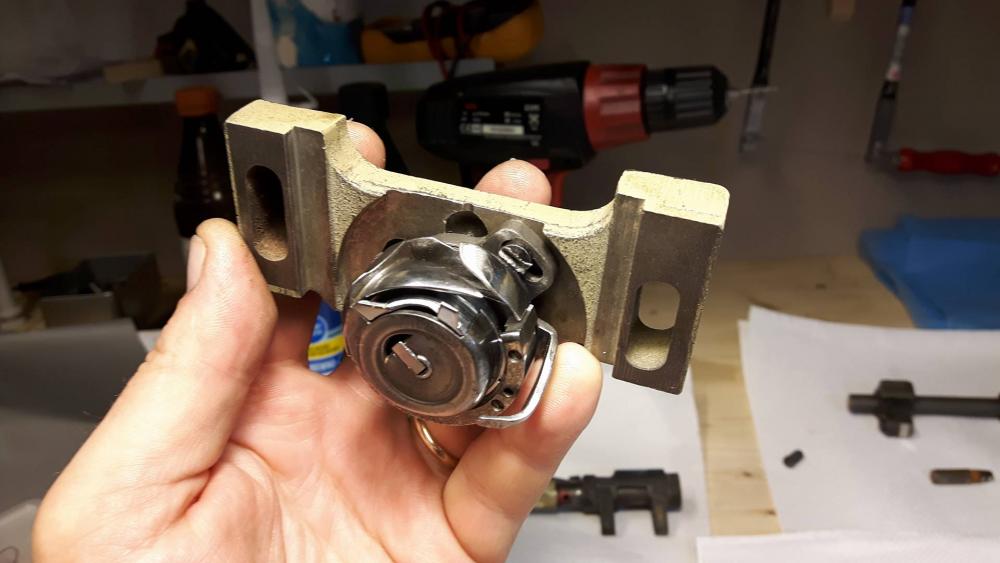

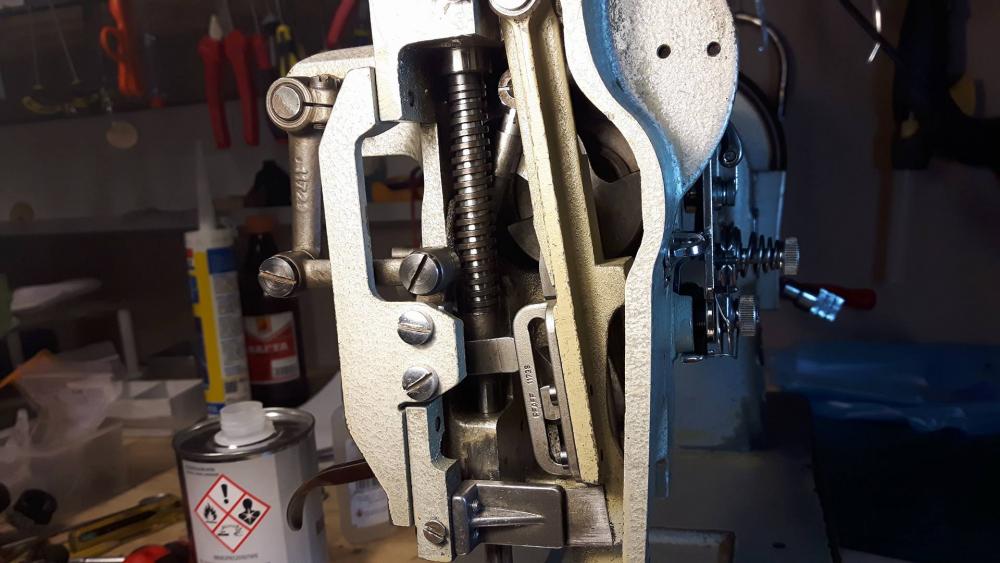

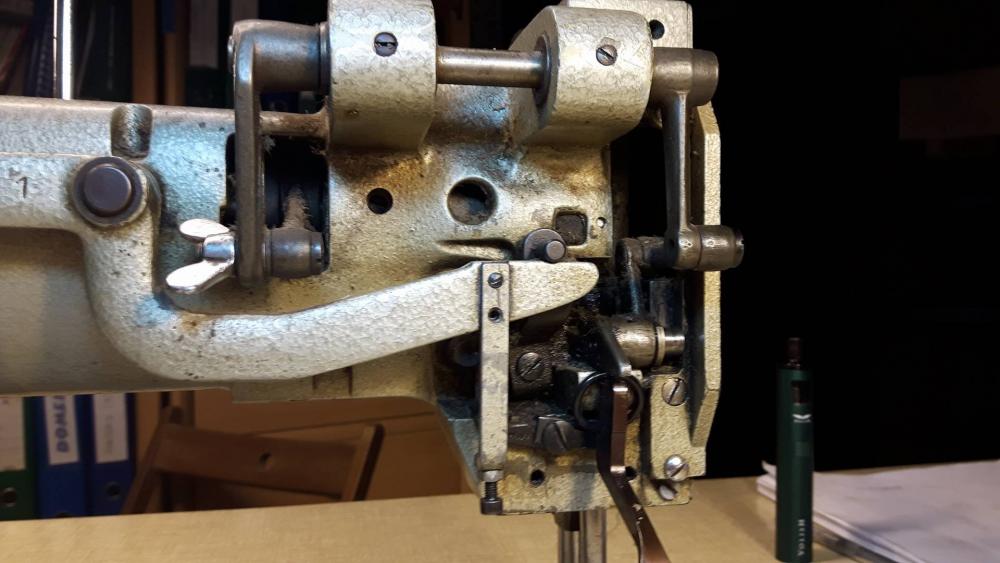

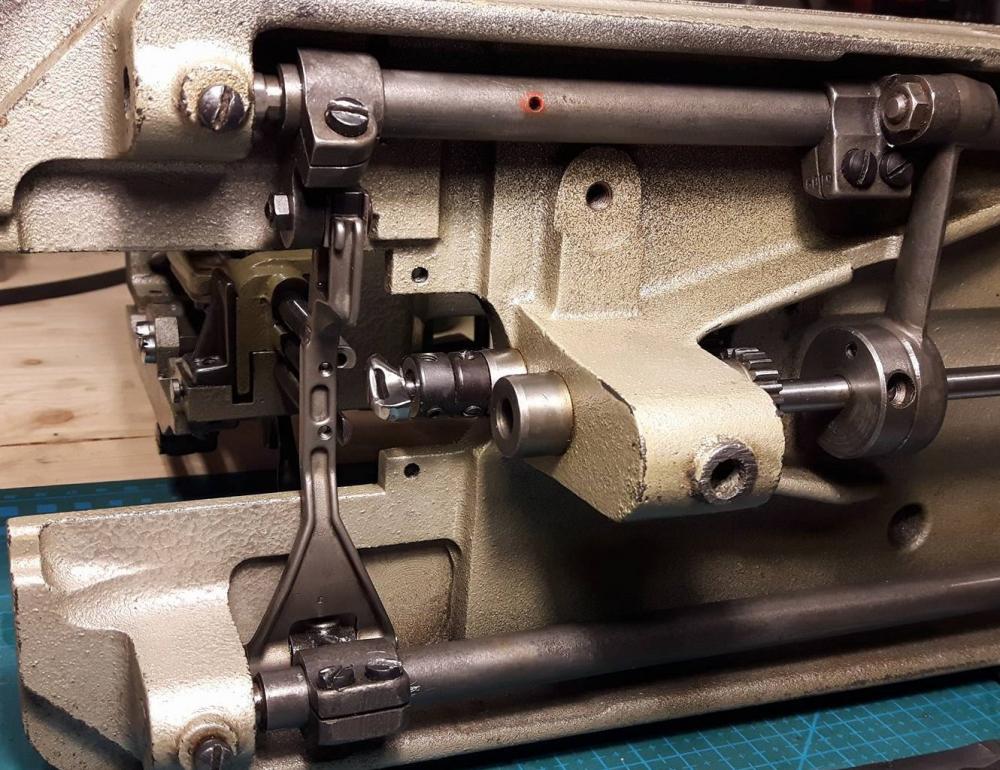

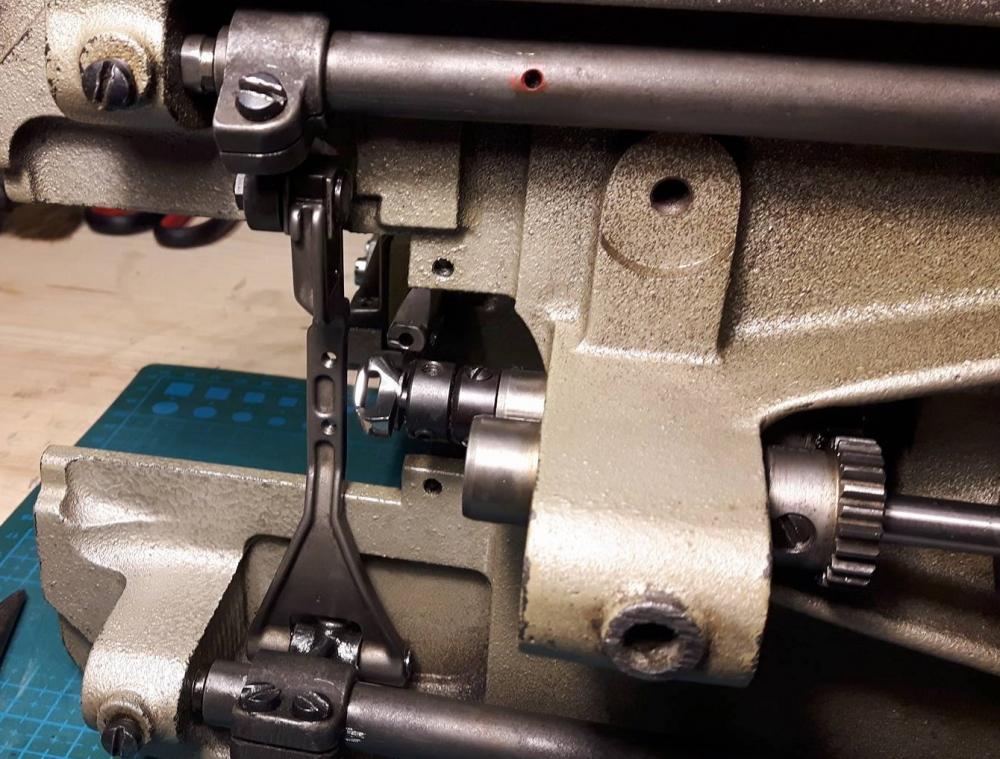

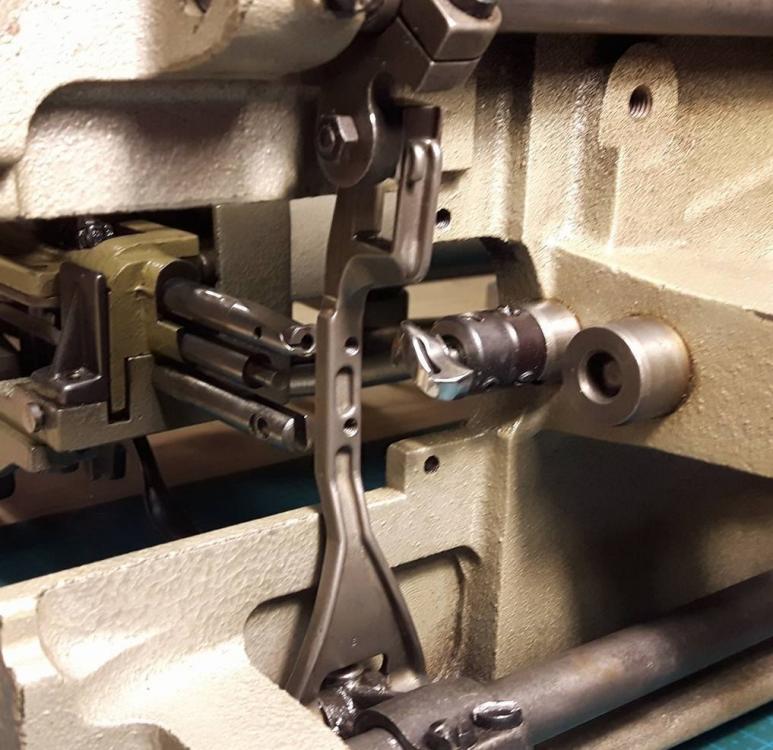

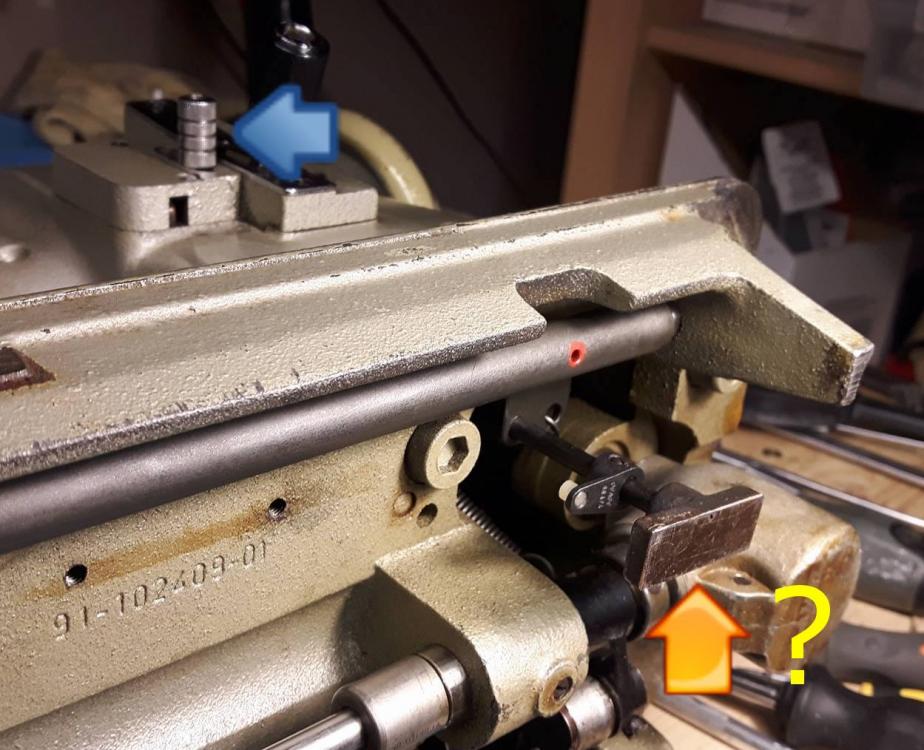

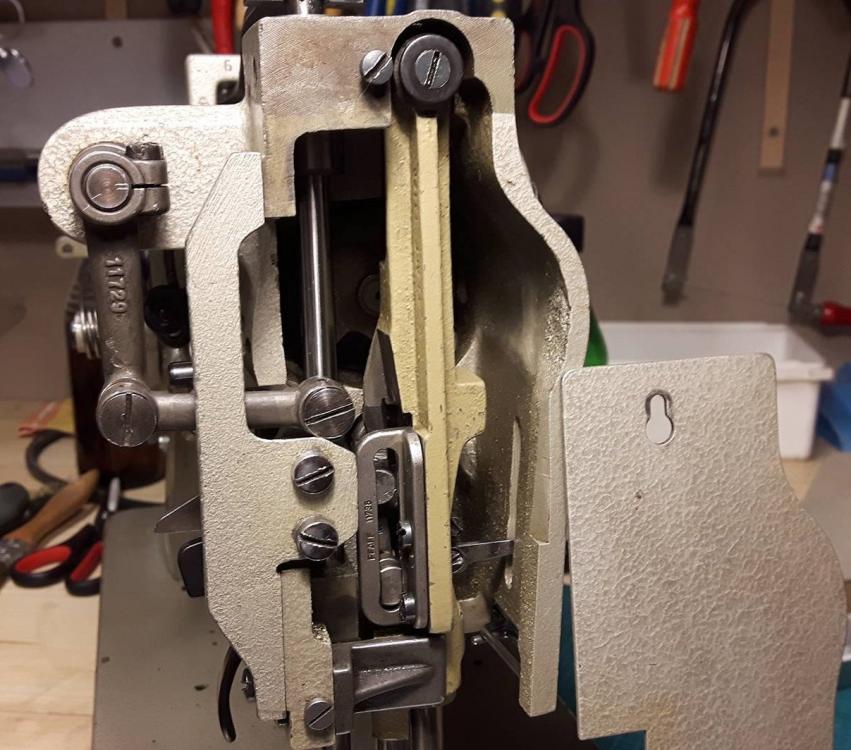

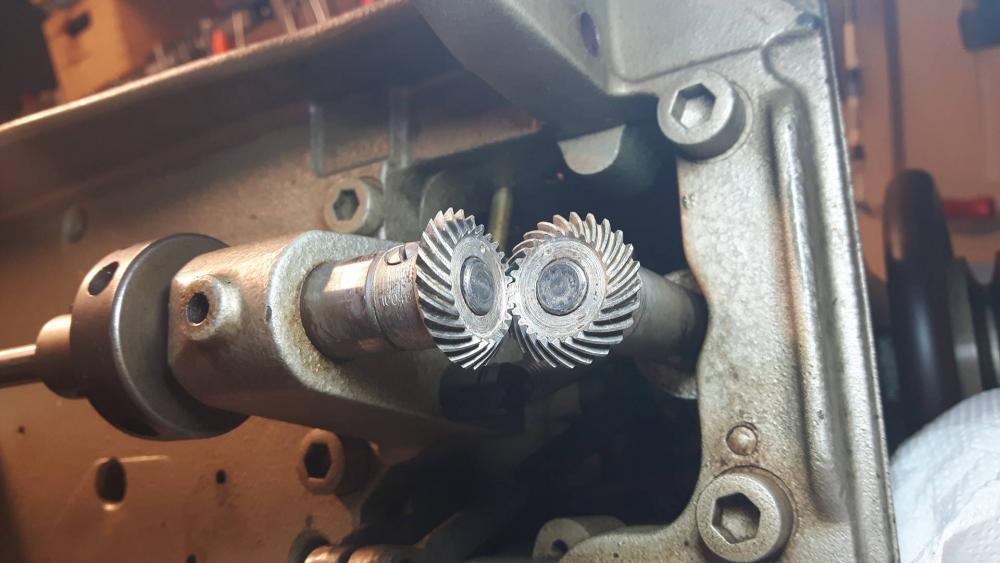

As we are going into details of my Pfaff mentioned in the previous post (link below) I created a new topic dedicated especially to this machine. So the bottom of the machine also has been cleaned up. Here are some photos including the looper Uwe asked for. The previous user forced the machine to work with 190 system needles, so knowing from the manual that this machnie is using 134 system needles I had to lower the needle bar to make the eye of the needle in the looper's range and also correct a looper timing. The looper has a flat sided shaft so losening the allen screws marked with green arrows allows to move the loper only left or right (closer or further to the needle scarf). Having no idea how to change the rotation of the looper I decided to loose both screws on the bottom gear marked with green arrows. Turning the lower gear turns the upper gear opposite and the looper as well. Turning the gear on its shaft also allowed to make no changes in the feed dog eccentric position. I am not sure if I did it properly - but have no service manual and no easier idea how to do this. The looper catches the thread properly and now I have to figure out the thread tension issue - explain later. I have a problem recognizing the unknown function of the brass foot I found on the right bottom of the machine (orange arrow). This is a block of brass fixed on the end of the vertical pushing rod. This rod can be pushed up and down. I can block this mechanism by changing the silver lever (blue arrow) position. Up position of this lever allows pushing the rod up or down and down position of this lever disangage (blocks) this function. The rod on its upper side is connected by the system of four arms with the kind of slider fixed to the lower horizontal shaft of the machine. Pushing this rod up changes the needle and presser bar position but only in their extreme forward or backward position. When both needle bar and presser bar are in their extreme forward position pushing the rod moves both bars 3-4 mm further to forward. The same situation is in extreme backward position of those bars; pushing the rod moves both them 3-4mm further to backward. I pressumed it would be a kind of 'afterburner' of the stitch lenght - but there is no possibility to pass the whole cycle of sewing while needle bar and presser bar are hitting one another and stucking in mid-position when the rod is pushed up. Does anybody have an idea of what this rod might be for? Bert

- 27 replies

-

- pfaff 4145

- pfaff 4143

-

(and 1 more)

Tagged with:

-

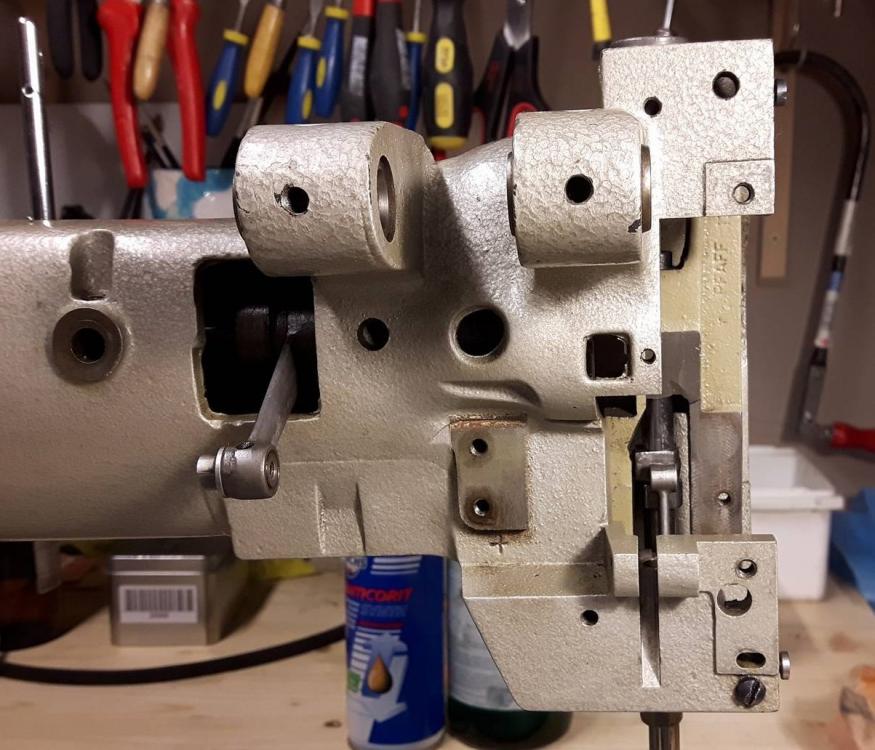

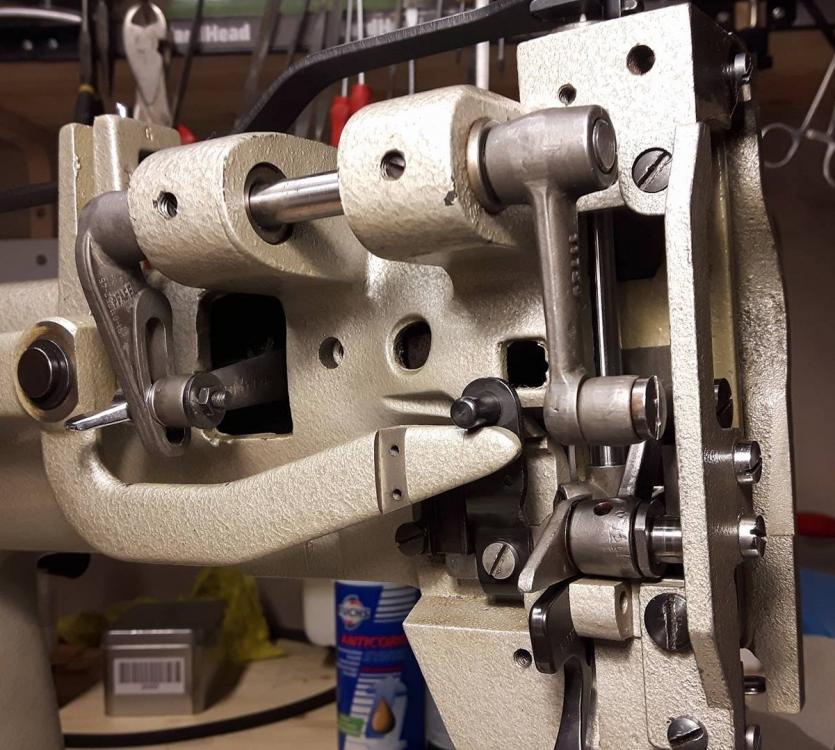

Thanks for the replies gentlemen. Special thanks to Uwe for the part of the manual however I have also found both manuals (for 145 and 4143). Yesterday I spent all the day refurbishing and figuring out how the rotation of the main shaft is transferred to all the parts powering needle bar, presser foot and lifting mechanism. So I can attach some photos of the uncovered left side of the head of the machne. Some photos show partially disassembled units and also assembled again after cleaning. This evening I am going to clean the bottom of the machine, so I'll also send some pics of the looper. And there are some missing parts but rather small (used or inproper screws) or the parts which I am not sure they are necessary in this very type of machine. I'll post all my doubts and questions when initial cleaning and research is done. Bert

-

Hi, I'm Bert from Poland, age 50, I'm interested in sewing machines. Now I just wanted to say hello and thank you for accepting me in the group. A few words about myself: About 3 years ago I became interested in the sewing machines and technical aspects of their functioning, later bought an old damaged sewing machine and the overlock and even managed to fix them. Recently I bought very cheap Pfaff 145 industrial machine . Actually it is a rare 4145 model, which I could see as a specific combination between the Pfaff 145 and the 4143. The machine is sewing but it is grossly neglected and requires general cleaning and adjustment. Therefore, I am now looking at posts in this group regarding the Pfaff 145 with interest. Later on surely I will have some questions, but first I want to check existing posts. And here are some photos of my machine. Regards. Bert

.thumb.jpg.84e6c967613adf050fa33614cecee4cc.jpg)