guntechholsters

-

Content Count

14 -

Joined

-

Last visited

Posts posted by guntechholsters

-

-

Hey y'all.

I want a way to cut out my wallet panels faster and I've looked at Cricut and silhouette. I actually bought a Cricut maker and couldn't figure it out so I took it back the next day LOL and I currently have a silhouette cameo 4 but it doesn't really seem up to the task. I'm only trying to cut 1 mm thick leather.

Does anyone here use some type of a machine to cut their leather out, besides a clicker and die of course LOL.

Thank you for any insight.

-

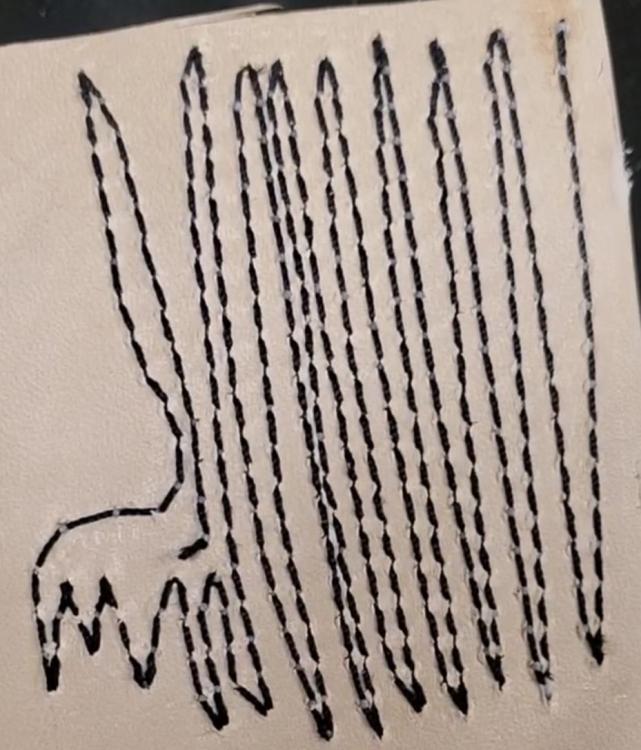

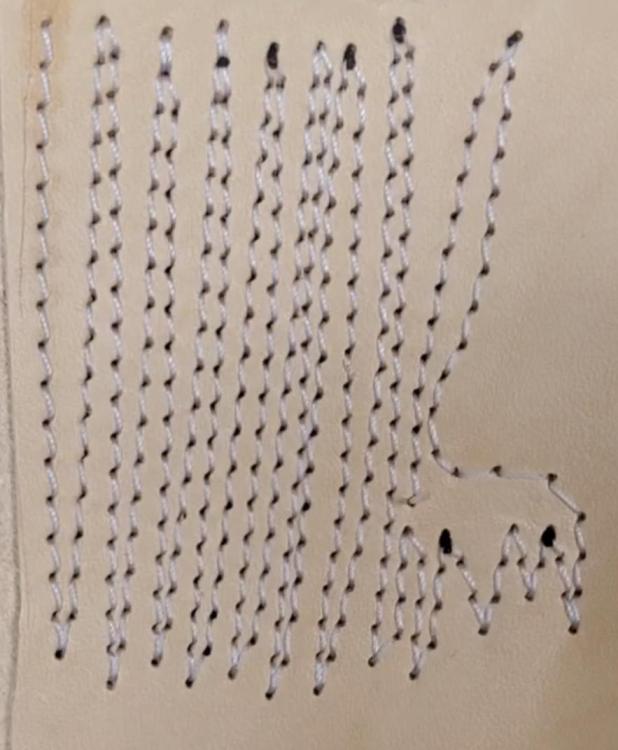

I've discovered something else I've been stitching

Where the knot is within the leather is actually shifting.

A couple stitches it could be perfect then the knot will suddenly move towards the back side of the leather and then it'll come back towards the top of the leather. I won't touch anything it'll just walk on its own it seems

-

Hello.

Would like something that can handle 3/8" thick leather and use #207 thread.

Thank you.

-

I very recently acquired this brand new, I've been having a few issues but I've been trying to work through oh, here's where I'm at right now.

I went back to basics, started all over and reset all tensions.

Running straight it looks good, the knots a little towards the back but not exposed so no big deal.

Still getting the knot pull through on turns though.I'm starting to think there is something wrong somewhere, perhaps a burr (although I looked and saw nothing anywhere). It seems when I make a turn, the tension on top increases or on bottom decreases.

I've rechecked to make sure my string is strung properly, I inspected for burrs, I'm at a complete loss.Unless someone has some idea that I haven't tried, I know not what to do to fix this. I have several wallets I need to get done that are piling up, back to hand sewing for awhile it seems..lol..

-

There is a gentleman not too far away from me sewing a Kenmore 6 Stitch machine he called it. He's asking $100 and says that he has sewn almost 3/8 inch leather with it. Does that seem like a good deal, looking at the pictures it looks nice

-

I'm thinking I should use a cylinder arm because it would make stitching the wallets considerably easier, at least in my mind. Is my thinking correct?

-

5 hours ago, charlie2crows said:For what its worth the max i have used on any wallet ever is 90 and I try to use 69. Smaller/medium bags 90 double stitched.

Depends on a few things - design, material and construction expertise being but a few considerations.

I do it all on three machines that are perfect - all drop shipped from the orient as some racist on here described them.

All cost about 25% of the prices you would pay from 'dealers'

May I inquire as to what machines you run?

1 hour ago, Wizcrafts said:I use #69 bonded nylon on wallet interiors and #92 when attaching the thin leather back to the interior. My wallets are usually well under 8 ounces thick along the sides and bottom. If I make a wallet that is at or over 8 ounces, I may use #138 thread. Almost any industrial walking foot machine can handle these thread weights. I refer to them as upholstery class machines. Visit any upholstery shop and you may find they have an old walking foot machine for sale after replacing it with a newer one. They run them hard and put them up wet!

I am in Omaha Nebraska I don't know if we have any upholstery shops around here but I'm definitely going to start calling today

-

Hello, I'm trying to Source some European leather, Tandy sells European bends which feel great but as I transition into apparel and accessories I need thinner leather, somewhere around 2 Oz.

I would love to get my hands on vachetta leather.

Any help is greatly appreciated.

-

Rocky, what you are doing is exactly what I want to do. Right now I own a holster company which is what I've done for about a decade but I'm wanting to expand more into purses and wallets and clutches. Would it be okay if I added you on Facebook and picked your brain a little bit?

-

Flat bed is better than cylinder for wallet work?

-

Getting more into making wallets, would like advice on what machine would be best.

Want to run 138 thread, bonus if I can use it to also make purses

Thank you.

-

Thank you

-

Looking for some advice. I've actually been a member for a long time lost my sign-in information had to start a new account and then I just managed to sign back in for the first time in several months.

Here's my dilemma, I'm currently running a ferdco 440r, I've been into leather work for several years now but it's always revolved around holsters and carry belts. I recently started to get into wallets and purses and clutches, fancier stuff LOL. I'm going to be replacing my ferdco with a cowboy 3200. I figure it will do my heavy work such as holsters and carry belts but I can also swap out the thread and needle and work on my other projects mentioned above.

With the wallets and purses and clutches and even dress belts I was wondering if a 138 thread would be more appropriate then 207? When I assemble my wallets I was thinking on the insides I could go with it and even lighter thread such as a 90 then do my edges using 138.

For showing the insides with a 90 weight thread I was thinking about picking up another machine something economical as well, any recommendations on that would be greatly appreciated I was thinking something like a cheap singer walking foot?

Any advice would be greatly appreciated thank you very much.

Leather pattern cutting machine

in Leather Machinery

Posted · Report reply

I did just purchase a laser engraver. I didn't know if it would be strong enough or how well a laser would cut through leather I would be afraid of scorching. Have you used this method?