Glaciersew

Members-

Posts

21 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Glaciersew

-

She’s broke....Singer 111w155 parts needed

Glaciersew replied to Glaciersew's topic in Leather Sewing Machines

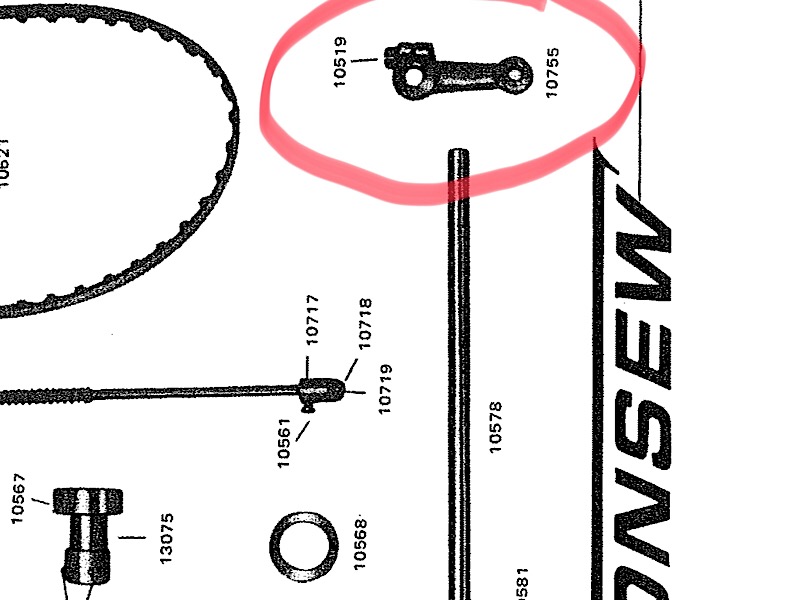

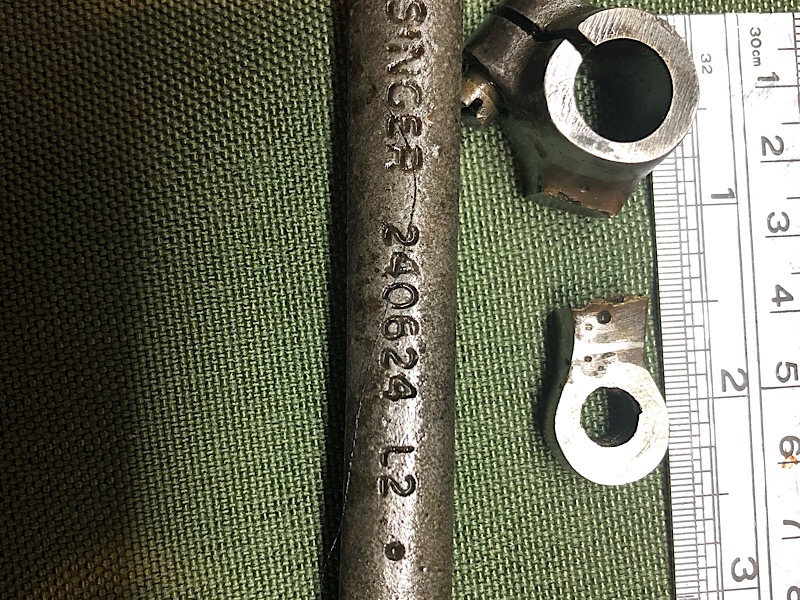

Have new antique piece. It clearly has correct part # stamped on it. The old looks to be home made. And the connecting rod is a different part # than what I’ve found in any manual. Now that it’s in the screw lines up exactly w the front access hole. Same for the wick in the rear. Should be fun getting her timed -

She’s broke....Singer 111w155 parts needed

Glaciersew replied to Glaciersew's topic in Leather Sewing Machines

Greatly appreciate ya looking! Thank you Seller backed out 111w100 so back to searching. In the mean time I did find a suitable replacement at the Consew NJ warehouse, just 20 minutes from home. Not sure what to do w the Singer. Repair and sell. OR repair and setup for binding operations just swap it out when needed. i can’t get over how easy it is to use the 206. I earned every straight line w the Singer. And it fell out of time more often than I can recall. Very happy w the new addition. -

She’s broke....Singer 111w155 parts needed

Glaciersew replied to Glaciersew's topic in Leather Sewing Machines

Found a 111w100 for $100 about an hour away. Hopefully heading there Monday morning. Hopefully it works better than it looks. Lots of rust from storage and general neglect. Seller claims it spins free. Fingers crossed! Can anyone vouch for Consew 226 parts being direct fit for 111w155? If option one fails this is another route. -

She’s broke....Singer 111w155 parts needed

Glaciersew replied to Glaciersew's topic in Leather Sewing Machines

It’s crossed my mind.... I’m on the hunt. -

She’s broke....Singer 111w155 parts needed

Glaciersew replied to Glaciersew's topic in Leather Sewing Machines

-

She’s broke....Singer 111w155 parts needed

Glaciersew replied to Glaciersew's topic in Leather Sewing Machines

Thanks guys. Looks like its been brazed once already. Gonna go that route for now and continue the search for a replacement. The top of the connecting rod had a wick that was dry when I picked it up. It appears to be the point of friction within the machine. -

She’s broke....Singer 111w155 parts needed

Glaciersew replied to Glaciersew's topic in Leather Sewing Machines

Thank you. I tried loading some pics. Wouldn’t allow anything over 1.4 meg. Is there another method of loading pics? Paid subscription? -

Managed to snap part #223693 Needle Bar Rock Frame Rock Shaft Crank Connection. I’ll most likely be looking for another machine to replace this one. If anyone has the parts please let me know Merry Xmas

-

I wish there was a “LIKE” button/feature for posts. Thank you Wizcraft!

-

Machine Choice Heavier Than A Juki 1541S

Glaciersew replied to stickandtin's topic in Leather Sewing Machines

Thanks for the info!!! I’ll leave her be. Have it it working perfect! Only acquired it in past 6 months. And now I have THE BUG! Looking for a similarly capable machine w reverse -

Machine Choice Heavier Than A Juki 1541S

Glaciersew replied to stickandtin's topic in Leather Sewing Machines

Wizcraft you mentioned a larger bobbin in a modified Singer 111. What’s involved in changing the hook & bobbin case. Is the larger a direct fit? Thank you -

Right angle piece hasn’t crossed my mind. Ive been looking at everything else. Thanks guys. It’s back to work after 51 weeks @ home. Reconstructive knee surgery was a huge success! 7 days a week at work for awhile. And daddy to 3 boys leaves little time for my new interest.

-

No. I wrote it as intended. It’s a walking foot compound feed machine. The needle and foot seem to snap backward as soon as they make contact w the feed dogs. I believe they should glide back simultaneously w the feed dogs.

-

As it sits the machine works well. I’ve disassembled and reassembled the area above the needle. Didn’t find any obviously worn parts. Or even parts that felt rough. The issue is when the needle and associated presser foot make contact w the feed dogs. The needle and foot go from front to rear much faster than the presser feet. With heavier materials it’s not an issue. While working w some lighter rip stop fabric I experienced some bunching or piling or the material. Any suggestions are appreciated. Is it unreasonable to think I should be able to work w lighter materials on this particular machine? Thank you

-

I have a non reversing walking foot machine. I’ve seen several methods for making the locking stitch, or backtac ? Curious what is your preference? Which, in your opinion works best? Thank you #1 spin work around and stitch over 4-5 stitches #2 lift presser foot slide work back. Insert needle and go back over stitches #3 when starting work. Position it backwards. Make 4-5 stitches and spin work around then move in your forward direction?

-

Singer 111w155 stitch length issues

Glaciersew replied to Glaciersew's topic in Leather Sewing Machines

Mission accomplished! The orientation of the set screws in the groove for the eccentric is key! Thanks you all for your time and the sharing of knowledge! -

Singer 111w155 stitch length issues

Glaciersew replied to Glaciersew's topic in Leather Sewing Machines

Once again Thank You!!!!! Y’all are incredible! Figured out the locking and adjusting screws earlier today. Im not sure how it happened but the belt appears to have jumped a tooth. Appears to be a relatively new rubber belt. Thanks to Uwe’s Consew 226 video I was able to get it back in time. Also found out that the eccentric gib locking screws weren’t in the groove. Needless to say EVERYTHING has been adjusted! Currently working on the hook timing. Once again one of Uwe’s videos is showing me the way. Not sure what it is but something has been binding. Didn’t think it was enough to be concerned about. The plan was to put it on the “list” of things to do. Well w all this tinkering it’ll proabbaly get torn down and diagnosed this week. -

Singer 111w155 stitch length issues

Glaciersew replied to Glaciersew's topic in Leather Sewing Machines

Thank you guys. I had this machine working perfectly last week. Well so long as I didn’t change stitch length. Timed w Uwe’s video, BTW the quality of your videos are amazing, and she was spot on. No issues at all. I tried changing stitch length last week and noticed the stitch length indicator wasn’t even close. Had to watch the eccentric and eyeball it. Last night it just started moving around on its own. just came in from trying the adjustments y’all recommended. The locking screws are the smaller screws. And the larger screws were use for adjustment. Correct?its difficult to tell in the singer manual. No luck. Now after attempting to set a stitch length I’m back to square one. -

Hello New Guy w another newbie issue. I’ve only had this machine a few weeks. Went ahead and set the timing, added a servo motor and it’s been great. Adjusted the stitch length a few times and that’s where trouble began. First off this machine doesn’t have a hole in front to show the numbers. Looking down through the top i noticed that the length indicated didn’t line up w a measured stitch. Really not a big deal. So at that time the machine was working just fine Last night w 2 short stitches to go in a project the stitch length went from approx 6 stitches to 32. I stopped made the adjustment back to 6 and then it did it again. The concentric doesn’t seem to be holding its position. what keeps the concentric locked in place? Thank you

-

Singer 211g 566 hook bobbin housing issues

Glaciersew replied to wendyp's topic in Leather Sewing Machines

I’m new to these machines as well. Just picked up a singer 111w155. I too was told it was working just fine when placed in storage years ago. The hook was 180degrees out. The starch length concentric was intentionally moved 3/8 to the im not 100% sure but believe your machine is a newer version of mine. This video is priceless for timing