-

Posts

15 -

Joined

-

Last visited

Profile Information

-

Location

EUROPE (Slovenia)

-

Interests

Bag making newbie.

LW Info

-

Interested in learning about

Bagmaking

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

alpinelite's Achievements

Member (2/4)

-

Ditching EFKA Vario DC motor....what do I loose?

alpinelite replied to alpinelite's topic in Leather Sewing Machines

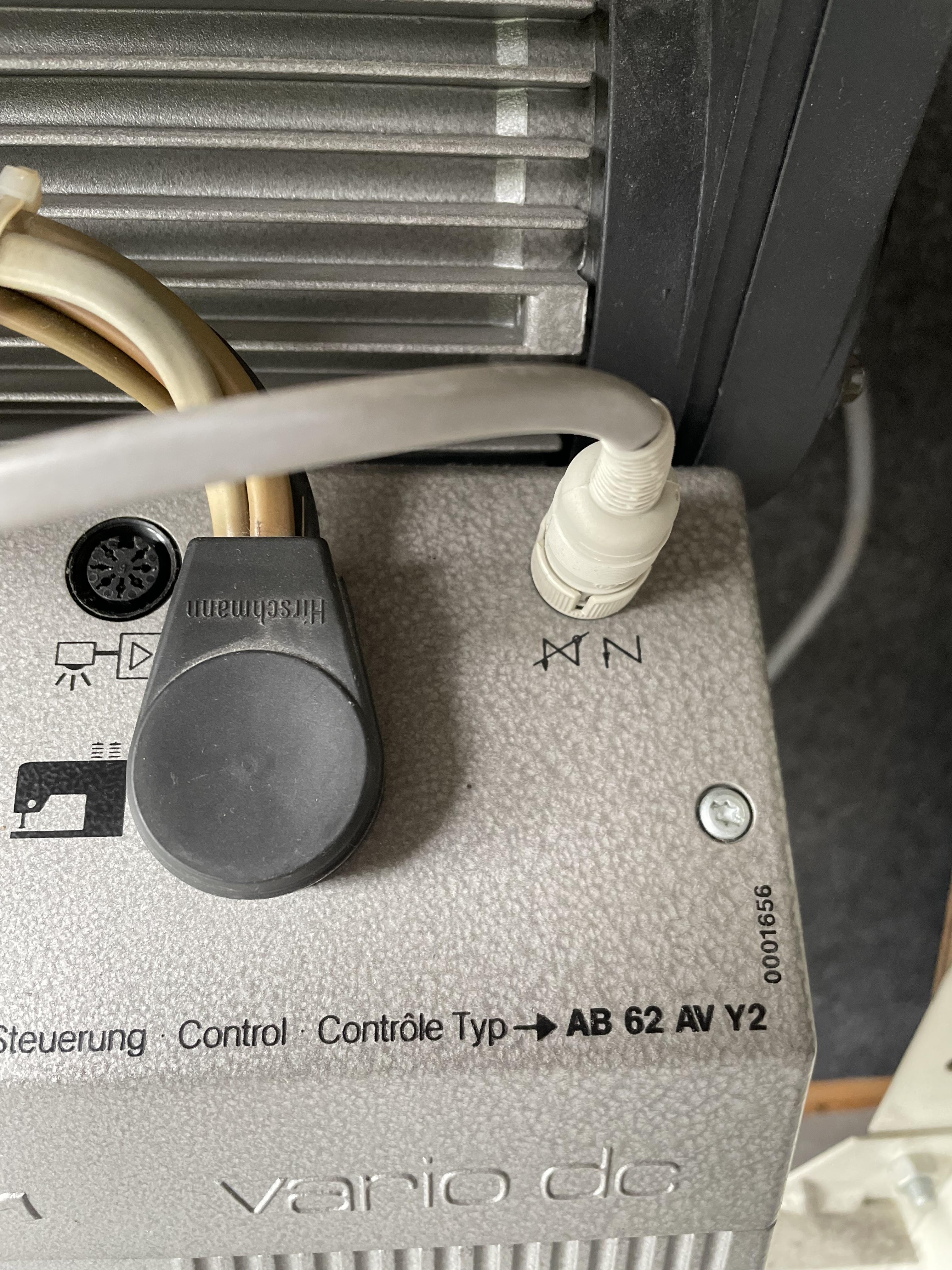

Hans, thanks. I have managed to check for position transmiter and its: EFKA P5-2 repl. P4-2 Q55 1436 CE -

Ditching EFKA Vario DC motor....what do I loose?

alpinelite replied to alpinelite's topic in Leather Sewing Machines

Hello, I have tried: Unpluged needle positioner and motor stopped and started signaling error. Unpluged needle positioner before starting machine and it started signaling when I started machine.. If I turn machine off and start it again I am able to do 3 or 4 stitches before it stops ans starts signaling. Needle positioner is EFKA but I was unable to read what type/model as I didnt have my reading glasses with me The plug looks like the one I have attached. You are menitoning 2 spinning discs...I reckon I need to remove the positioner cover and do what? This is my first time dealing with positioner. If I can fix this it would be awesome as I got intimidated with the service costs they have quoted. Thanks -

Ditching EFKA Vario DC motor....what do I loose?

alpinelite replied to alpinelite's topic in Leather Sewing Machines

Yes I have read that manual and according to the signaling error I have an issue with position transmiter. I have reached EFKA service company to confirm and they quoted the above repair. Do you think position transmiter needs readjusting? If I unplug it from the control box machine will not work. Best regards, -

Ditching EFKA Vario DC motor....what do I loose?

alpinelite replied to alpinelite's topic in Leather Sewing Machines

-

Ditching EFKA Vario DC motor....what do I loose?

alpinelite replied to alpinelite's topic in Leather Sewing Machines

Hello Hans THANK you for willing to help. Do you have email I can reach you directly to help solve the control unit issue. I can send you some pictures. Best regards -

Hi, I recently picked up barely used Juki LZ 2286 for 100EUR. Its a tri step zigzag machine I would use for bag making purpose. Anyway it came with EFKA Vario DC Motor that is faulty. Something to do with needle positioner or electronics so I was quoted 300EUR for repair. So I wonder if ditching EFKA and going with 750W servo motor with no fancy electronics is the way? What do I loose? I mean I can probably set up a knee lift and can cut the thread with snips etc. Thanks for your insights!

-

HI I have a chance to buy old but fully functional Pfaff 1246 machine and was wondering if it can be rated similar as workhorse Pfaff 1245 or twin needle means trouble and stay away. Would use as single needle (as its currently set) for sewing thru EVA foam/cordura/canvas/leather type of fabrics. Thanks for all replies!

-

Bernina 217 cam reader installation

alpinelite replied to alpinelite's topic in Leather Sewing Machines

Thanks, its older version with small cams....same cam size as domestic 830 model. Both 217 are old versions 6mm zig zags. Thank you -

Bernina 217 cam reader installation

alpinelite replied to alpinelite's topic in Leather Sewing Machines

Anyone that can help? Thanks -

Hello, I got lucky and found Bernina 217 with all the original cams (20 cams) and cam reader. Cam reader works but I would like to move it to my other 217 I am currently using. Both machines are 6mm zigzags. Anyone knows how to remove the Cam reader and re instal it? Amongst the original cams there is a Cam with nr. 10113 but I believe that's not 3 step zigzag cam despite being pictured as such in the original (German) manual? Thank you!

-

Hi, I was using my Juki 5410 Needle feed with Coats Epic80 Tex40 without any issues. Now I swaped to bonded nylon Coats Nylbond 60 tex45 and the bobbin thread snaps while I sew. I start normal but during the sewing there is a noise as if the thread gets overstretched (stretching string sound) before it snaps. Otherwise the seam formation looks fine. The bobbin was inserted anticlockwise. Thoughts? Thanks

-

Hello, this has been probably covered but cant find the threads so asking....what one needs to convert OLD pfaff 335 into binder. My idea is to use flatbed machine for sewing and convert my old 335 into binding machine to use with 2cm binding tape without fold. What do I need to buy to swap out? Are there any complete binding Kits available online in Europe? Thanks

-

I cant print that on standard A4 in 1:1 scale. Can you post pdf. file...thanks

-

Hello, newbie here looking for help to decide with what power servo motor old Pfaff 335 would work well. I recently bought the old Pfaff 335 and want to replace the heavy/noisy clutch motor it came with. Local Jack servo motors supplier said that this size machine needs at least 750W servo to work well but I was reading that 550W servo works just as great. Anyone made the swap for 550W and how does it work for you? I am planning to use machine as binder to bind the bags edge. Bags are mostly made with up to 1000D cordura fabric and have multiple layers of fabric and webbing (backpacks etc.). Will not sew heavy leather just upholstery fakes. Options I was looking at are: https://www.college-sewing.co.uk/store/JK-511A-1-220V-550W-SERVO-3_4-HP-MOTOR-WITH-NEEDLE-POSITION https://www.college-sewing.co.uk/store/JK-561A-220V-750W%3d1HP-SERVO-MOTOR Sorry if the topic was already started but I couldn't find the info. Much Obliged